A New Generation of Double Pumps

Hengli’s HP21VG series of axial piston variable double pumps boast high performance, compact design, and high power density that can meet a customer’s application requirements of high pressure, high speed, frequent shock, and other harsh working conditions.

Overall, these pumps feature a concise, high-performance design that uses fewer parts than previous hydrostatic products. The more compact design gives design engineers more freedom and flexibility in system design.

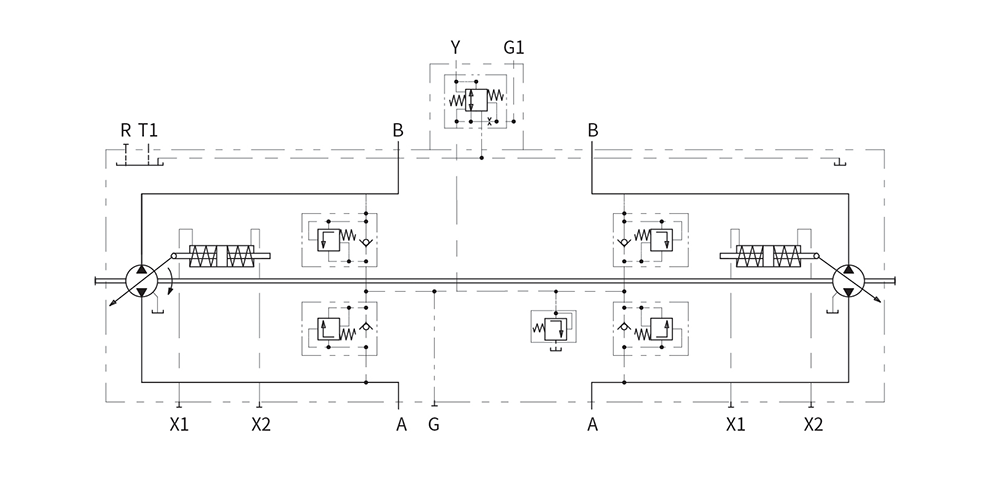

The HP21VG’s variable pump working circuit is closed circuit with pressure of 42-45 MPa (6,091-6,526 psi). Hydraulic, electric, and mechanical servo controls can be developed according to customers’ needs, and DA or emergency brake valves can be integrated as well. The pump is spline shaft driven, with working oil port A/B on the same side of the casing, with direct acting high pressure relief valve, without bypass and charge pump.

Features and advantages

High efficiency. Control of hydraulic flow rate and direction by an electrohydraulic integrated servo system ensures extremely low servo pressure and superior high power density. The extremely high operating efficiency allows the HP21VG series pumps to reduce the total cost of ownership.

Compactness. The low number of total components and the compact arrangement of the oil ports and control valves substantially shorten the overall pump length and facilitate installation in tight spaces. The compact design coupled with the high-pressure and speed ratings gives it a higher power density ratio.

Better design. Using a low-noise casing while optimizing the structure of the flow distribution plate helps meet the low noise requirements of the whole machine for hydraulic components. Strengthened shaft and bearing parts ensure the rotary accuracy of the pump and make it operate reliably ultrahigh pressure.

Control options

Hydraulic control, electric proportional control (voltage 12V DC and 24V DC), mechanical servo control, and other control options are available to meet the needs of multi-industry applications.

Multifunctional combination. The pump can be integrated with DA or emergency brake valve to obtain newer and better functions. For example, when the DA valve is integrated, the HP21VG closed double pump can be given a special control method to achieve stepless adjustment of hydraulic pump displacement.

In practical applications, the HP21VG series closed double pump can be used with any existing Hengli motor to form a hydraulic drive system to realize fluid transmission and control. As described above, it can also be used with DA valve to realize functions such as automatic driving and hydraulic DA of the vehicle, which is a good helper for hydrostatic travel system.

For example, in the actual application of skid steer loader, the main pump uses the HP21VG45 axial piston variable closed double pump, and HRP series radial piston motor to form a strong, efficient, automated, low fuel-consumption hydrostatic closed travel system that can meet the traveling condition under full load and the traction condition when shoveling. Moreover, smooth transitions while starting, stopping, or turning results in a more comfortable driving experience.

Based on the development of electrification, the HP21VG closed double pump is easily compatible with Hengli’s HLEC6448A series or HL-C series controller to enhance the functional adaptability of the whole machine.