Advanced Products and Game-Changing Engineering are Trending for Fluid Power Pros

The NFPA released a November 2016 survey on the “State of the Fluid Power Industry.” The study notes that distributors see annual shipments for their overall business during the next 12 months being nearly 90% better than the prior 12 months. Behind that growth in hydraulic businesses are three trends: (1) availability of new intelligent products, (2) game-changing additive manufacturing as a tool for engineers, and (3) services that help businesses fill skill gaps for hydraulic professionals.

The NFPA released a November 2016 survey on the “State of the Fluid Power Industry.” The study notes that distributors see annual shipments for their overall business during the next 12 months being nearly 90% better than the prior 12 months. Behind that growth in hydraulic businesses are three trends: (1) availability of new intelligent products, (2) game-changing additive manufacturing as a tool for engineers, and (3) services that help businesses fill skill gaps for hydraulic professionals.

Intelligent digital and axis control servo and proportional valves, and pumps, are gaining traction for more and more machine builders. While the benefits of better flexibility, modularity, and less wiring are well known, many businesses were not comfortable with the technology. But manufacturing and processing plants are now placing a high value on the ability to tune a valve with software. In paper mills with a hundred axes, digital valve technology offers less wiring and the ability to tune pressure control on the fly, leading to improved quality of the paper produced, reduced maintenance, and increased productivity.

There is also increasing interest in electro-hydraulic actuation (EHA) products, a “power by wire” system combining hydraulic and electric technology. EHA is a self-contained actuation system that receives power from an electric source and transforms an input command signal (usually electrical) into motion. This system is ideal for a large press manufacturer, for example, because it helps to save energy, reduce piping, or address environmental cleanliness. It is now another option in a tool box helping machine builders who want a competitive advantage and new motion control solutions.

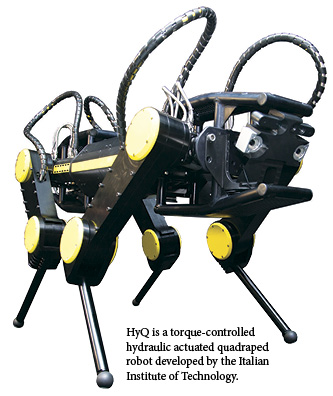

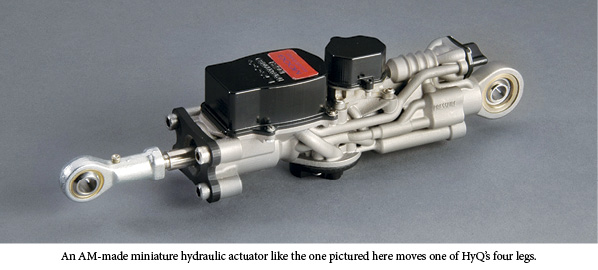

Additive manufacturing (AM) is another way engineers are innovating the fluid power industry; experience shows that this has become a game-changer for customers. Most people know that AM helps with rapid prototyping, thereby getting new designs to market faster and compressing production time from months to weeks. In 2017, you’ll see engineers increasingly working on developing products with unique flow paths and material properties that weren’t possible with traditional machining practices. One example of this is a case where engineers were able to fundamentally integrate a miniature servo valve and actuator with the same body to save space and increase the performance available in a small package. The product is a miniature hydraulic actuator, which controls the legs on a new servo-powered advanced robot called HyQ, which was engineered with AM. The process enabled engineers to offer complex geometries, reduce envelope size, and achieve reliable performance.

Additive manufacturing (AM) is another way engineers are innovating the fluid power industry; experience shows that this has become a game-changer for customers. Most people know that AM helps with rapid prototyping, thereby getting new designs to market faster and compressing production time from months to weeks. In 2017, you’ll see engineers increasingly working on developing products with unique flow paths and material properties that weren’t possible with traditional machining practices. One example of this is a case where engineers were able to fundamentally integrate a miniature servo valve and actuator with the same body to save space and increase the performance available in a small package. The product is a miniature hydraulic actuator, which controls the legs on a new servo-powered advanced robot called HyQ, which was engineered with AM. The process enabled engineers to offer complex geometries, reduce envelope size, and achieve reliable performance.

One of the challenges the industry faces is the difficulty finding new employees who are trained and educated in fluid power technology. One of the ways companies can succeed is by providing services that allow customers to access hydraulic motion control expertise, such as technical support, hands-on training classes, and on-site field services to help fill the experience gap. These trends will, hopefully, create exciting opportunities for future fluid power professionals.

Dave Brodzinski is sales manager for Moog’s Industrial Group business in North America. He can be reached at dbrodzinski@moog.com.