Eaton Rolls Out a Winning Solution for Bowling Ball Maker

The Brunswick Corp., Lake Forest, Ill., has been throwing strikes for nearly two centuries now. Founded by Swiss immigrant John Moses Brunswick, the company originally opened for business as a manufacturer of carriages in 1845. Soon after, however, the founder took a tremendous interest in billiards and decided to manufacture billiard tables, which were mostly imported from England.

His tables quickly became a commercial success, and the business has been on a roll ever since. A major part of that success was the expansion into the sport of bowling, which included the manufacturing of balls, pins, and bowling alley equipment. Late in the 19th century, Brunswick revolutionized the way bowling balls were made by using vulcanized rubber. Before that, balls were made of solid wood. Today’s balls are made with engineered plastics.

Challenge

Most of the Brunswick bowling balls are made at the company’s plant in Reynosa, Mex. Water is used as a lubricant and as a cooling fluid to machine the balls to a precise roundness with the necessary high-gloss finish.

That precision, unfortunately, produces a buildup of small plastic particles that need to be routinely removed from the water. Hydraulic fluids are also used during the process and so is grease to keep the machinery properly lubricated. That combination was further muddying the water.

To remedy that, Brunswick was relying on two antiquated gravity filtration systems with paper roll media to clean the mix of water, oil, plastics, and chemicals. The cost to maintain the filters was approximately $1,500 per month, which would have been acceptable had the filters been operating efficiently, but the filters were not.

As if the situation wasn’t already dampened enough, chemicals also needed to be added to the water to prevent unwanted foaming.

Meanwhile, because the Mexican government enforces stringent water regulations and due to the buildup of hydrocarbons and organics, the rancid water had to be regularly hauled away and replenished with a fresh, clean supply. That was costing Brunswick another $2,000 per month.

Expensive, inefficient, and polluting, the filtration system at Brunswick had to go.

Solution

Eaton was called and soon, the diversified industrial manufacturer was throwing strikes of its own with Brunswick.

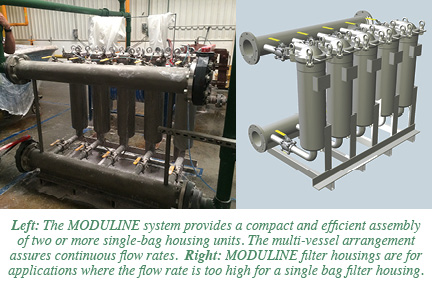

Eaton developed a two-stage filtration process. In the first stage, a five-station MODULINE filter bag vessel with nylon mesh filter bags was installed for the removal of the coarse plastic particles. Next, a six-bag MAXILINE™ filter with polypropylene felt bags was put into operation for final polish. This second step was to ensure clean water went back into the system. At the end of each workweek, maintenance staff installed Eaton oil adsorption inserts in the MODULINE, and Brunswick ran the system to remove any further traces of oils and hydrocarbons.

MODULINE systems are ideal for applications like Brunswick’s where the flow rate is too high for a single-bag filter housing. The individual vessels can each be isolated for cleaning and bag replacement while maintaining system flow. The manifold assembly permits the flow to go through all housings simultaneously with a single inlet and outlet connection. Eaton’s MAXILINE systems provide a user-friendly, cost-effective filtration solution for higher flow rates, providing the perfect solution for the high-volume, highly efficient requirements at Brunswick.

Results

Since completion of the Eaton conversion, water quality and supply problems are no longer an issue.

“At the end of the day, the water quality to the machining center was excellent and all rancidity problems were effectively eliminated, as well as the need to haul and dispose of water,” explains Carl Berthold, regional sales manager for Eaton. “That’s great news for us because regardless of water application, Eaton is dedicated to minimizing any negative impact on the environment around the world.”

That’s great news for Brunswick, as well, and for more than just the huge gains in achieving the excellent sustainable business practices now in place.

Brunswick has not had to pay to discharge water for six months, according to Berthold. Energy, labor, supplies, and maintenance costs associated with the old machines have been eliminated, and so have the costs associated with the anti-foaming chemicals.

How much so?

“The MODULINE/MAXILINE combination has paid for itself in seven months,” notes Berthold. “That’s an ROI that any company would be very happy to throw at you.”