Clean Air Act: Battling Contaminants in Pneumatic Components

By Mike Parzych, Product Marketing Manager, Norgren

Actuators, air motors, grippers, and many other pneumatic components in almost all industries use compressed air, but performance requirements and design parameters vary widely. In life sciences, for example, compressed air drives small, lightweight, high-precision respirators. Patient-care devices require the same reliability and controllability as rail-car braking systems, automotive assembly, metal stamping, food and beverage dispensing, packaging, commercial vehicles, industrial automation, and energy production. Despite the different scale of each of these applications and the unpredictability of the environmental temperatures in which they operate, they all depend on precision and control.

Automotive manufacturing, for example, employs compressed air for the painting, cleaning, press-room, and assembly area production lines, and it’s commonly used to operate robotic end effectors. Compressed air is essential to create auto parts because it lifts, positions, and moves fastening machines. But no matter the application, for the system to perform as required with the longest possible service life, the air supply must be free of contaminants. Oil, for example, can keep paint from adhering to surfaces, and it can cause cracking, flaking, beading, or future corrosion. Unremoved water can stick to pipe walls and block the path of the compressed air. Solid particles such as rust can clog nozzles and compromise the surface of the finished product.

In machine shops, where compressed air operates grinding machines, air guns, and water recovery units, if the air contains too much moisture it can condense on colder surfaces, causing corrosion in the metal work piece or the tooling.

In short, because of the versatility and variety of pneumatic systems, regardless of the application requirements, compressed air must be clean, dry, and delivered at the appropriate pressure. Unless contaminants are filtered out, they compromise proper operation and shorten the life of the equipment.

Compromising compressed air

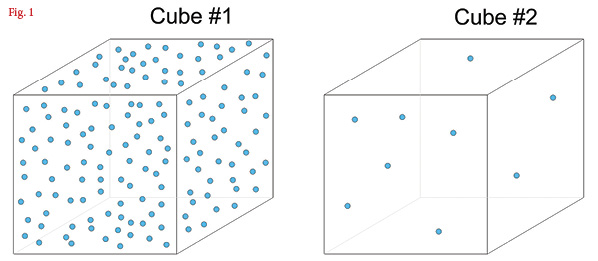

Compressing atmospheric air converts it into potential energy that can be stored, distributed, and used as a source of power for pneumatic systems, tools, and processes. This compressed air retains nitrogen, oxygen, other gasses, water, hydrocarbon vapor, and solid particulates such as dust or heavy dirt measuring as much as a millimeter. Compressing this mix concentrates solid contaminants and heats the air so that it holds more water vapor. In addition, the oil that lubricates the compressor can enter the air stream as fine mist, aerosol, or vapor. Even air leaving oil-free compressors can pick up oil vapors from atmospheric air and pass them into the air-distribution system.

The now-hot air leaves the compressor, passing through a heat exchanger into an air storage receiver and distribution pipework. As the air cools, water and oil vapor condense and turn to liquid or emulsions. An efficient condensate management drainage system can remove these elements. But entrenched solid particulates and any remaining water and oil vapor travel downstream into the distribution system. The air can then pick up even more contaminants such as rust and debris from old receivers, treatment equipment, and pipework.

There is a clear connection between the presence of moisture, particulate, and oil in compressed air and a whole range of disruptions such as less-efficient processes and damaged tools and equipment.

To remove the water and contaminants present in compressed air requires intervention just before or after the compressor but before the air reaches the tools and equipment. Operators can apply many point-of-use air-preparation components at this point. One is an inlet filter, which prevents dirty ambient air particles from entering the compressor in the first place. Another component is a water-removal filter installed between the outlet and the air receiver; it reduces the moisture in the stored air. As air in the receiver cools and vapor condenses, the liquid water and emulsions fall to the bottom to be drained. After the receiver, a coalescing filter can remove oil aerosols and water carried from the compressor. Another installation to consider is a general-purpose filter. When placed at the main header, it removes water and particles 40 microns and larger.

The air is compressed, moisture and oil vapors are condensed and drained, water is removed, and large particles are filtered out. This general level of air preparation may be enough for many industrial uses, but tools can extend their life and effectiveness with the addition of the right filtration, pressure regulation, and lubrication.

An application with high-speed pneumatic tools or process-control instrumentation requires filtering out particles down to 5 µm. Paint spraying and food-related applications require filtration down to 1 µm or less. But applying such a fine filter to the entire distribution system significantly increases initial equipment costs and maintenance in the form of filter replacement. It also drives up operating costs because a finer filter makes it more difficult for air to pass through, producing a pressure drop. And increasing air pressure to compensate raises the total cost for compressed air.

Generally, it is inadvisable to provide filtration finer than absolutely necessary because fine filter elements trap more dirt and become blocked more quickly. For an effective workaround, employ standard air-line filters as prefilters; this reduces the risk of overtaxing high-efficiency elements with coarse particles.

Oil is another contaminant found in compressed air. Oil can exist in three forms – oil/water emulsion, aerosol, or oil vapor. While standard air-line filters can remove emulsions, only special coalescing filters can remove small particles between 1 µm and 0.01 µm. These filters are typically rated by the amount of air they can process at a given cleanliness level, normally a maximum remaining oil content of 0.01 ppm in the exit air. Flow that exceeds the rating increases not only pressure drop across the unit but also the remaining oil content. It also increases energy costs. Air-line filters mounted immediately upstream protect coalescing filters from particulate and water contamination.

Oil vapor is typically present in such minute quantities that it can be ignored, except in sensitive applications such as food and beverage processing, pharmaceuticals, and breathing air. Passing the air through an absorbing bed of activated carbon after it flows through standard and coalescing filters removes the oil vapor.

After taking all contaminants into account, consider the degree of cleanliness for each machine or part of a plant. Using the right filter in the right location minimizes energy and maintenance costs. Always determine the volume of air involved in each stage because undersized, inappropriate filters are a prime cause of high energy costs.

Point-of-use filtration

In selecting point-of-use filtration, the first thing to assess is the end-use equipment itself. What does it require? Find the answer in the operating manual. Manufacturers of tools and machines powered by air specify the appropriate level of filtration, beginning with purity classes of compressed air with respect to particles, water, and oil. After identifying that level, the end user can specify a filter that meets the requirements. But there are important variables to keep in mind.

- Even after filtration at the main distribution point, additional contaminants may seep into the air stream via the pipework.

- Residual moisture may condense as the air moves through the distribution system.

- Harsh operating conditions, such as salt sea air, high humidity, or caustic environments, can compromise air-preparation equipment.

Countering such situations requires components with robust construction and specialized sealing materials. Some applications benefit from the addition of multistage filtration: a prefilter, a fine-particle filter, and a coalescing filter to remove oil. Using a prefilter to remove larger particles prevents the finer filter from clogging and prolongs the service life of the finer filter element. Applications benefiting from three-stage filtration range from instrument air for precision fluid control to large offshore oil rigs using compressed hydrocarbon gas.

Regulating pressure

All pneumatic equipment has an optimum operating pressure. Exceeding that pressure won’t yield greater productivity; it will, in fact, cause excessive wear while wasting compressed air. To use compressed air most efficiently, reduce the pressure of air leaving the compressor to the precise level the application requires.

Systems tend to operate at two pressure levels: compressed air stored in a receiver at high pressure (which optimizes filter performance and energy efficiency), and air used by actuators and other devices, usually at a pressure 10% to 20% lower. This arrangement ensures the compressor is not constantly running.

Regulators, that is, pressure-reducing valves that control pressure, have two important performance characteristics: regulation, maintaining consistent outlet pressure regardless of inlet pressure, and flow, maintaining consistent outlet pressure regardless of flow rate. The precision of regulation and required flow dictates the type and cost of the regulator.

Most regulators fall into one of four categories: general purpose, pilot operated, precision, and special purpose. Most general-purpose regulators are diaphragm types, though piston versions are used where equipment demands higher flow capacity for a given size. Adjusting manually operated knobs or handles lowers downstream pressure without actuating downstream equipment. To adjust a nonrelieving regulator to deliver lower pressure, cycle downstream equipment or use a 3/2 shutoff valve to expel excess air.

Pilot-operated regulators control outlet pressure by means of an air-pressure signal produced by a precision regulator. This means, for example, it’s possible to mount the regulator in large distribution mains but control it remotely from the shop floor. Engineers usually use this type of control when a continuous process requires a large, steady air flow.

Precision regulators are normally used for instrumentation applications in which fast response, exact repeatability, and control of outlet pressure are necessary. These units have a limited range but superior flow and regulation characteristics. Precision regulators also can relieve up to 90% of their flow for specialized applications, such as tensioning belts, paper rolling, and balancing.

Special-purpose regulators can be based on any of the other types with application-specific modification. For example, they may be constructed of special materials like stainless steel, have high relief flows, or operate with a plunger instead of a hand wheel.

Combination filter/regulators clean air and control pressure in a compact unit, saving space and costs. Specialized filter/regulators remove fine particles of oil, offering precise regulation.

Lubricants

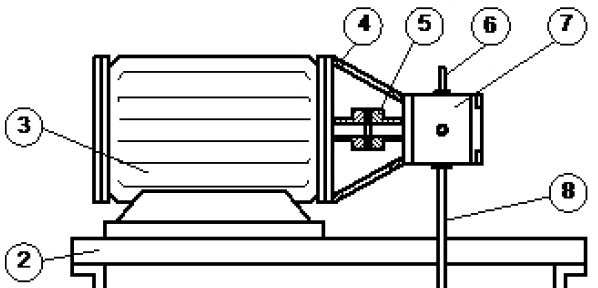

To ensure that operating equipment performs efficiently without excessive resistance to wear, we need to introduce a lubricant, usually oil. Aerosol oil-fog lubricators use reservoirs or bowls filled with oil, which, when generated, have relatively large oil particles that cannot rise or travel far before dropping out of the air stream. Therefore install oil-fog lubricators near the equipment they are meant to service but never below it.

There are also microfog lubricators, which atomize the oil in the bowl, creating particles less than 2 µm in size. This fog can travel upward and for long distances through complex feed lines. Microfog units can also ensure proportionate distribution through numerous lubrication outlets, making it ideal for multiple valve-control circuits. Only about 10% of the oil in a microfog system becomes an aerosol, so it works well in applications requiring only small amounts of lubricant. By adjusting the drip rate, oil delivery can be raised to approach that of an oil-fog lubricator.

One other type of lubricator is a positive-displacement injection pump. It does not continuously deliver lubricant like aerosol lubricators but instead injects the same amount of lubricant every cycle. This type is often used on conveyor chains where several injectors can be joined together on a manifold to treat different points at the same frequency.

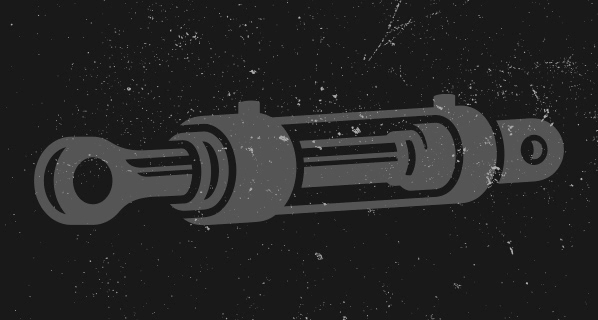

Most valves and cylinders powered by pneumatics are prelubricated and in most applications do not require additional lubrication during their service life. Once they reach the end of their lubrication life, nonrepairable cylinders must be replaced. Other components can be repaired, but technicians must apply new grease before they are put back into service. In addition, contaminated air gradually compromises the original grease lubricant and shortens the seal life.

Lubricated air prolongs the life and performance of prelubricated components. Applications that have high cycles, operate at high speeds, or use large diameter bearings can generate heat that speeds up the deterioration of internal lubrication. Lubricated air is also essential for equipment that is not prelubricated, for example, pneumatic hand tools such as screwdrivers.

Lubricated air extends cylinder life, but it also washes out the original lubrication. So once lubricated air is introduced, it must always be used. The amount of oil for sufficient lubrication varies with each pneumatic device, so it is important to follow equipment manufacturers’ recommendations. From regular inspections and servicing, technicians can determine the optimum setting and adjust the amount delivered.

Safety

Compressed air is powerful, so it is important to have safety features built-in to the pneumatic system to protect equipment and personnel.

The first safety consideration is overpressure protection. Components in pneumatic systems often have a pressure rating lower than what is generated by the compressor. If for some reason the regulators do not maintain safe working pressure (SWP), downstream components exposed to excess pressure can malfunction or fail.

The most common overpressure protection is a relief valve. This device holds system pressure at a constant level at or below the stated SWP. Relief valves should operate only when the system exceeds regulated pressure, so they need to be set to a pressure higher than that for the regulator. Frequently, relief valves are situated too close to the system operating pressure, causing the relief valve to vent air during normal operation.

The relief device must also be sized to match or exceed flow through the parts of the systems it protects, without system pressure rising above the acceptable overpressure level.

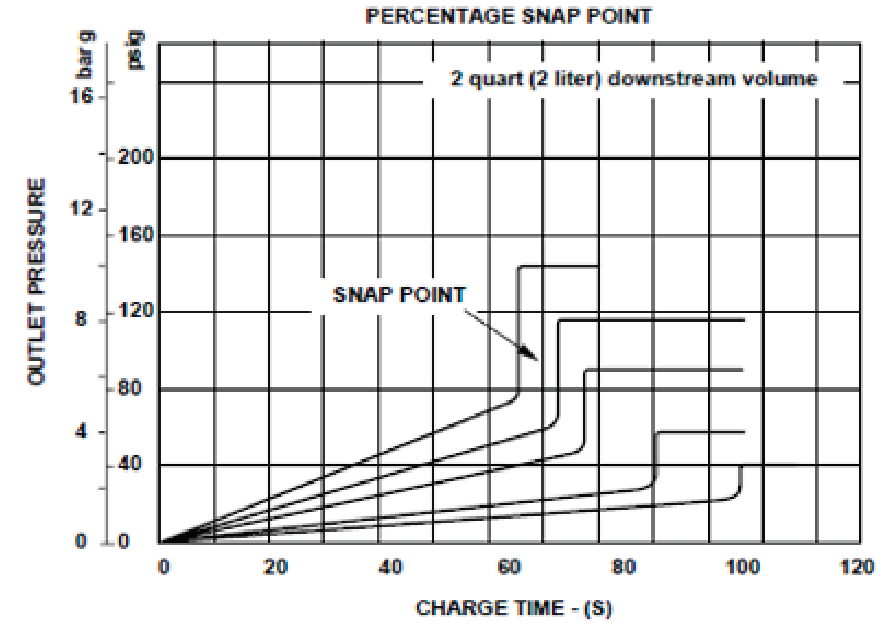

Finally, consider start-up. Loading during start-up can cause unnecessary wear on moving parts, and sudden movement can injure personnel. Soft-start valves prevent such problems. They let air gradually bypass from a compressor to the pneumatic system. Adjusting the valve controls the rate of pressure buildup. The valves usually have a spring-operated internal poppet design, set to open, or “snap,” when pressure reaches between 40% and 70% of full-line pressure. It is more economical to set these devices near the equipment they are intended to protect rather than fit a larger valve to the whole distribution system.

We’ve mentioned many of the challenges to proper air preparation presented by such variables as harsh environments. Numerous industrial processes require extremely high pressures, and these must be carefully monitored. When faced with such conditions be aware of the various kinds of sensors capable of detecting pressure and switches that can open or close a connection based on the pressure level. Options include simple but effective electromechanical pressure switches, electronic pressure switches with few moving parts and offline programming, and pressure transducers or transmitters that convert pressure into an analog electrical signal.

A recent study from Research and Markets estimates that the smart pneumatics market will grow by nearly 7% between now and 2026. This growth depends on equipment effectiveness, which is itself determined by IIoT factors. Predictive maintenance will save up to 12% over scheduled repairs, reducing overall maintenance costs up to 30% and eliminating breakdowns up to 70%. For fluid power systems, says the report, this “means a whole new level of condition and remote monitoring.” In short, compressed air generation, properly installed and maintained, can deliver years of trouble-reduced operations.