Eliminating Water Hammer: It’s a Must

By Sheila Kennedy, CMRP, Additive Communications Managing Director and Brian Strait, Business Development Manager, Check-All Valve Mfg. Co.

Water hammer can be so damaging to machinery and dangerous to human health that every effort should be taken to prevent this hazard. Also called hydraulic shock, water hammer sounds like a mechanical noise and is sometimes perceived to be a valve slamming closed. In reality, it is a phenomenon that occurs in piping systems when fast-moving fluid stops instantly, or reverse flow begins. The sudden change in momentum or direction induces the hydraulic shock wave, creating what sounds like a loud bang.

The jarring water-hammer noise is a recognizable symptom of a serious problem. Though short-lived, the pressure or shock wave will reverberate all the way through the fluid-handling system until it eventually dissipates. The banging or hammering sound is a result of the pressure spike traveling through the media, bouncing back and forth against the pipe walls, valves, and other obstacles in its path – putting them at risk of damage or destruction. OSHA accident reports detailing water-hammer incidents illustrate the potentially harrowing nature of its effects.

Because of its risks to equipment reliability, process performance, and safety, it is essential to prioritize the elimination of hydraulic shock and its costly consequences. Proper valve selection and sizing can help avert the damaging effects of water hammer. Spring-loaded check valves, designed primarily to prevent the reverse flow of media, are uniquely effective at minimizing if not eliminating the phenomenon.

Understanding the problem

Compared to industrial systems, the water hammer heard in household plumbing probably won’t do much damage. When a kitchen-sink faucet running at full force is shut off suddenly, or a washing machine finishes filling, the abrupt stop causes the surge of water to slam against the pipes. Recurrences over time can loosen a pipe’s connections or joints, potentially causing a water leak. To mitigate further hydraulic shock, the pipes can be tightened and secured, and devices such as pressure reducers or water hammer arrestors can be installed.

In industrial fluid processes, where the hydraulic shock is more powerful, the system is more extensive, and the components are more sensitive, the risks of water hammer are greater. Usually a liquid is involved, but it can also occur with a gas, steam, slurry, or multiphase fluid. When a forced stop of fluid or abrupt change in fluid direction creates hydraulic shock, the transient pressure spike and shaking effects could destroy anything from pressure sensors and flow meters to pumps, boilers, and entire piping systems. For instance, pressure spikes can travel into a pump and damage its impeller and drive.

Water hammer can destroy equipment, even knocking pumps off their moorings. The degree of damage caused by the momentary spike in fluid pressure depends on the intensity of the shock wave. But even mild water hammer can gradually degrade a system. It is best to assume there is no “safe” level of water hammer and to work toward its elimination.

Operational and human costs

Failures arising from water hammer are extremely costly, not only in terms of repairs, replacements, and process downtime, but also due to the serious health, safety, and regulatory repercussions.

Significant operational effects may include cracked, ruptured, or burst pipes; blown gaskets; fractured fittings; damaged valves; leaking joints; compromised supports and pipe racks; destroyed expansion joints; collapsed structures; and disabled process equipment such as pumps, boilers, and steam systems.

Severe injury or death can result for people in the vicinity if steam or hot condensate forcefully escapes, fluid-carrying hazardous chemicals are released, or equipment fragments are forcefully propelled into the air.

Tackling the cause

Properly designed pipeline systems won’t experience water hammer. Choosing the right valve type and components for the given media and application is essential to an efficient, effective, noise-minimizing fluid system. Valve styles that stop reverse flow or backflow before the flow direction changes will significantly minimize if not eliminate water hammer.

Earlier check valve designs were subject to hydraulic shock. For example, traditional swing check valves depend on flow reversal and gravity from the weight of the disc to fully close. The swing check valve’s disc, a moveable flapper, sits on a hinge pin, and forward fluid flow pushes it open. Reverse flow causes it to slam shut, returning it to its seat, though it doesn’t always close quickly enough to completely prevent backflow; or, when it does close, it can do so very rapidly. Both conditions induce the damaging pressure and shock wave of water hammer.

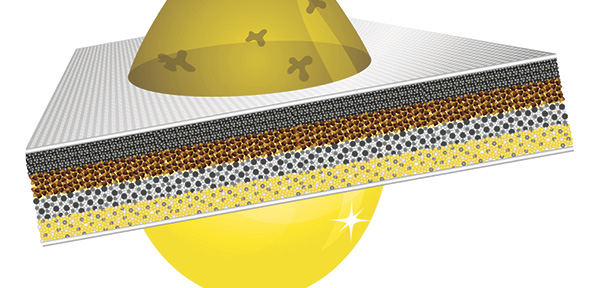

On the other hand, modern spring-loaded check valves tackle the cause of water hammer by design. Inline spring-assisted check valves allow media (typically liquids, gases, and steam) to flow in one direction. Media flow and pressure drop cause the spring to collapse, allowing the valve to open. The spring closes the valve quickly and smoothly as the forward velocity of the fluid slows down or stops, preventing flow reversal.

The most effective check valve style combines three characteristics. First, spring-loaded check valves incorporate a spring to assist in closing the check valve before fluid flow reversal, thus avoiding water hammer. They function equally well in vertical or horizontal positions with proper spring selection.

Secondly, poppet-style check valves are spring-loaded to help close the valve prior to fluid flow reversal, preventing water hammer. They incorporate a disc as the checking mechanism, normally at the end of a sleeve or stem. Designed to reduce maintenance costs, the seating surfaces are parallel to each other, thereby preventing the excessive wear that can occur in plug, cone, and ball seats.

Finally, silent check valves are engineered to operate silently by closing quickly and smoothly. They utilize a spring to assist the poppet in closing the check valve before fluid flow reversal.

When selecting a spring-loaded check valve, its style, size, flow coefficient, cracking pressure, seat material, and temperature rating are among the important considerations. Ideal designs ensure that the media flows over smooth, contoured surfaces with a minimum change of direction to minimize pressure drop. The orifice size will be engineered to give a minimum pressure drop over the full flow range of the valve. Also, the valve will ensure positive sealing by inducing turbulence on the seating surfaces just before the valve closes, helping to remove any minute foreign particles suspended in the fluid.

When designing to avoid water hammer, other factors are at play, such as avoiding having pumps output into vertical lines; avoiding having multiple pumps feed into a common header; and identifying the optimal valve locations within a piping system. Also be aware of industry standards and regulations regarding water hammer’s hazards.