Line Drive: Bucher Leans into the E-Mobility Market

By Michael Pyper for Bucher Hydraulics.

About a year ago, the Swiss group Bucher Industries acquired the Mobile Drives division of the Lenze group. Based in Romanshorn, Switzerland, the specialist in frequency inverters and DC/DC converters for commercial vehicles has been integrated into Bucher Hydraulics, which already provides hydraulic drive expertise within the group. The company now sees itself as being ideally equipped for the electric mobility of the future.

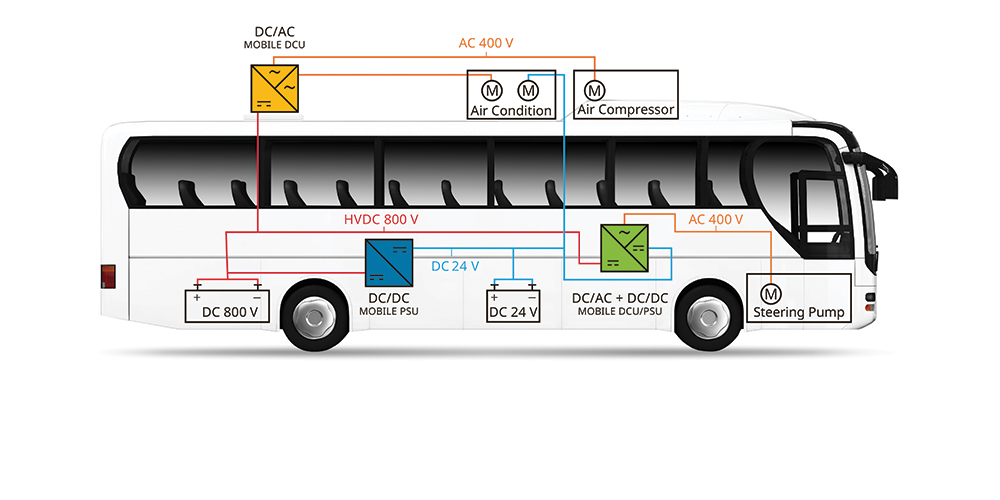

Typical auxiliary drives in a city bus.

“The world needs to decarbonize to tackle climate change. That’s why the future of mobility is electric,” said Andreas Schnurrenberger, head of sales and product management for electrohydraulic systems and mobile drives. The acquisition of Mobile Drives and its integration into Bucher Hydraulics has significantly strengthened the division’s position as a supplier and partner in the e-mobility market, benefiting manufacturers of buses, trucks, and mobile machines.

The business acquired by Bucher Industries is a pioneer in electromobility. Founded in 1989 by a handful of idealists, some of whom are still onboard today, it means that Bucher Hydraulics now has unique expertise in the field of multi-inverters and DC/DC converters for electrically powered commercial vehicles. As early as 1995, an electric traction drive with an integrated vehicle charger was developed. Over the years, project business in the bus and truck sector has resulted in important requirements for the current platform, called MOBILE, which can implement a wide range of drive solutions quickly and easily. Since 2014, Mobile Drives has been supplying customers in the automotive industry with products tried and tested in large-scale production, together with ECE E1 approvals from Germany’s Federal Motor Transport Authority.

A comparison with inverters from the industrial sector shows how essential experience is, especially in the mobility sector.

“While such components fail after a very short time on test benches that simulate the environment, the Mobile Drives products easily withstand the specified load cycles,” Schnurrenberger said, not least because a new product has to fulfill several hundred qualification tests before it goes into series production.

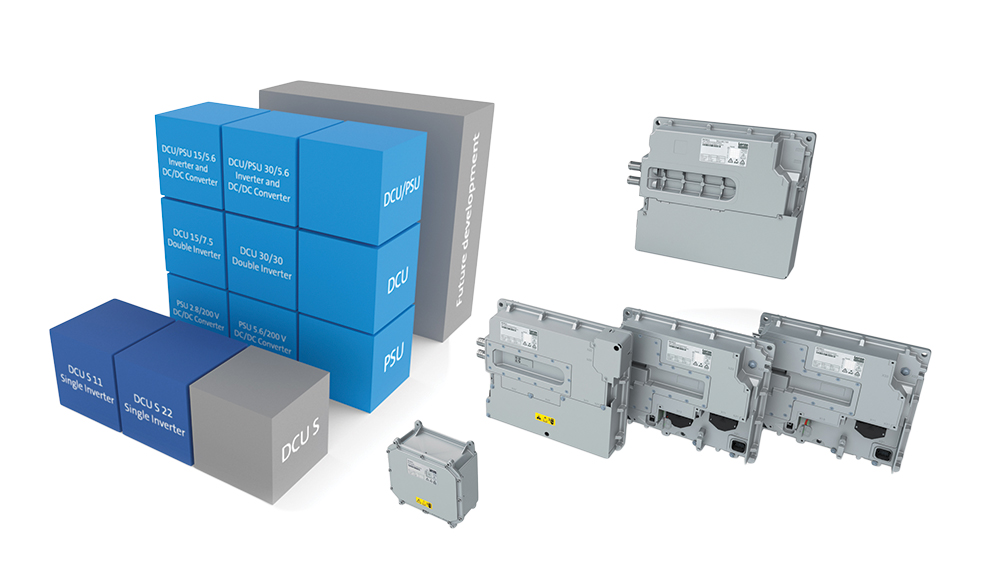

Modular system

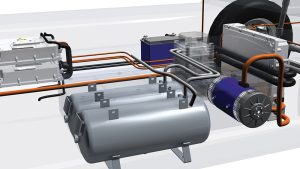

The inverters and DC/DC converters supply electrical auxiliary drives such as air compressors, pumps, or compressors. Combined devices also convert the voltage of the traction battery into the 12 or 24 VDC voltage required for the vehicle’s onboard electrical system. With a maximum input voltage of 848, units are already equipped for future 800 VDC fast-charging stations.

The modular principle makes it possible to meet vehicle manufacturers’ individual requirements with customized software but largely standardized hardware. The compact, standardized housings significantly increase the long-term availability of spare parts and reduce their variety in production and customer service.

“After all, e-buses have now been in service for up to 20 years,” Schnurrenberger said.

In buses and trucks, every cubic centimeter of installation space is at a premium. That is why the product portfolio includes double inverters that can supply two actuators from just one housing, which saves on space and costs.

‘Powered by hydraulics’

The know-how acquired in the field of commercial vehicles can be transferred to mobile machines. Here, too, electric drives with batteries or fuel cells are increasingly replacing fossil-fuel diesel engines. The work functions are still commonly powered by hydraulics, which combine high forces with maximum ruggedness and low space requirements. As a provider of innovative hydraulic drives, Bucher Hydraulics is developing electrohydraulic solutions to make mobile machines more efficient, quieter, and longer lasting. This also results in solutions with enormous energy savings by means of recuperation.

“The Mobile Drives business segment,” Schnurrenberger said, “is committed to efficiently and reliably converting energy for electrically powered vehicles such as e-buses, e-trucks, and mobile e-machines. We are therefore ideally positioned to deliver the drive solutions of the future.”