Advanced Surface Analysis of Mechanical Seals

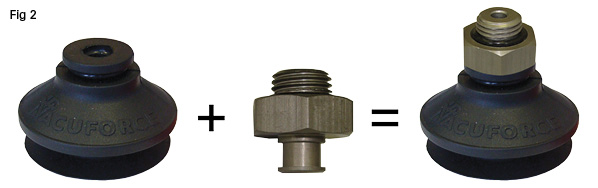

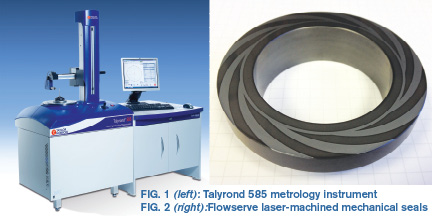

Flowserve Corp., a provider of flow control products and services for the global infrastructure markets, has harnessed the high-accuracy surface measurement capabilities of AMETEK Taylor Hobson’s Talyrond 585 metrology tool to analyze micro-features laser machined onto its most advanced mechanical seals. In developing the mechanical seals, Flowserve pioneered entirely new laser-machining techniques at its Temecula, Calif., facility that involved incorporating micro-features, such as waves and concentric grooves, onto the faces of its seals.

The Flowserve seals were developed for use in harsh environments and highly demanding applications, such as pipelines, boilers, pumps, and compressors, where seals would often come in contact with highly abrasive or difficult-to-handle materials at elevated temperatures and pressures. The advanced surface features are designed to greatly extend the life of some seals, allow them to run without making contact, or eliminate leaks and other operational issues.

To develop the seals and ensure their performance, Flowserve needed a reliable, easy-to-operate surface measurement tool. It required a high-accuracy instrument that could repeatedly measure seals in a range of diameters and contours with complex surface features and made from a variety of materials. The Talyrond 585 proved up to the task on all counts and, combined with proprietary Flowserve software, established itself as an integral, complementary instrument in the company’s analytical laboratory.

In developing this series of instruments, Taylor Hobson combined its experience in high-accuracy surface measurement with its expertise in ultra-precision machining. The resulting Talyrond 585 is a metrology tool able to perform three core measurements (roundness, contour, and surface finish) on a single platform.

The versatile instrument has a measurement resolution of 0.3 nm, a key advantage in measuring complex micro-features. It has a high-resolution gauge for linear or circumferential surface roughness measurement; frictionless air-bearing spindle and precision column for roundness, cylindricity, and straightness measurements; and a patented calibration technique for the measurement of radius, angle, height, length, and distance.

The instrument provides a cost-effective solution for accurate and repeatable measurements that previously required up to three separate instruments to perform. Along with analyzing Flowserve mechanical seals, the instrument is well suited for a range of applications, such as precision automotive and aerospace components.