Pushing Hydraulic Fluids Forward

By Blayne McKenzie, Technology Manager, Industrial Oils, The Lubrizol Corporation.

Today’s hydraulic machines have undergone significant design modifications in recent years, but their importance in modern industry is unchanged. The overall growth of the global hydraulic equipment market, including in Asia Pacific, Europe, and the Americas, shows no signs of slowing. It is expected to continue expanding at a compound annual growth rate of 4.13% through 2024.

Indeed, hydraulic systems are responsible for reliable operation in countless critical applications, and it’s important that they perform to the best of their abilities throughout their lifetimes. And as hydraulic systems themselves continue to evolve, so too must one of their most essential components for optimal operation: hydraulic fluids. This article walks through the necessary performance characteristics required in modern hydraulic fluids, and it explores the greater potential for new improvements that can be made with advanced performance polymer technology.

Operational conditions

Operational conditions

Today’s hydraulic fluids must contend with increasingly harsh operating conditions, as OEMs continue to iterate system designs to maximize machine efficiency while controlling costs. Achieving both goals simultaneously can create new challenges for fluids to contend with. For example, hydraulic fluid sumps have been a primary target of downsizing, which has been an effective weight-and-materials reduction strategy for OEMs. But it necessitates that smaller volumes of hydraulic fluids perform the same amount of work throughout the hydraulic system. As a result, the fluid necessarily operates at higher temperatures and, because there is less time for fluid to cool within the sump between work cycles, it remains at elevated temperatures for extended periods of time.

These conditions have detrimental results on a hydraulic fluid’s ability to provide its essential functionality. Consider that one of the most important characteristics of a high-performing fluid is its ability to retain its designed viscosity throughout use. Sustained higher temperatures elevate a fluid’s potential to lose viscosity and become thinner and thinner. As the fluid loses viscosity, its protective film layers are compromised.

Those layers are critical, particularly in strenuous high-speed applications in which maintaining film thickness is critical. If a fluid loses its film thickness at such speeds, the fluid will not be able to deliver the expected protection, and parts can become worn prematurely throughout operation. For end-user operators, worn parts can lead to compromised machine performance and even machine failure. Either situation can become detrimental to an organization’s bottom line, as the resulting repair costs and production losses due to downtime add up.

This all makes viscosity retention a critical performance characteristic in modern hydraulic fluid formulations. The deployment of high-performance additives and performance polymers in the contemporary formulations can help significantly. To demonstrate these capabilities, Lubrizol’s testing team recently compared several experimental ISO 46 hydraulic fluid formulations to validate the potential of a new ethylene-propylene copolymer (OCP) that can enhance viscosity retention. The testing compared a multigrade fluid formulated with OCP (PP1) and versions of a multigrade fluid with a more conventional polymer, poly alkyl methacrylate (PP2).

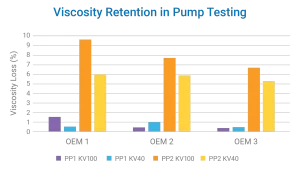

First, both formulations were subjected to OEM pump testing. The data was clear: PP1, containing the new technology, exhibited low viscosity loss and retained viscosity well across many hours of service. This leads, of course, to greater retention of protective film thickness.

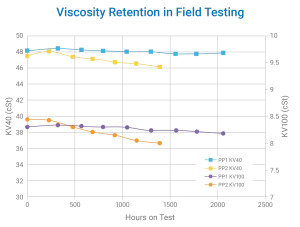

Second, in order to demonstrate the polymer’s applicability to real-world environments, we subjected each formulation to many hours of testing in tough field environments. The application was a hydraulic telehandler. Depending on the attachment mounted to the end of its boom, a telehandler can be used as an all-terrain forklift, crane, aerial work platform, or even an excavator – each of which represents a challenging duty cycle with high shear potential for an applicable hydraulic fluid.

In our testing, we found that PP1 once again delivered exceptional viscosity retention across thousands of hours of work. While PP2 also demonstrated strong shear stability, the elevated performance of PP1 can make a significant difference for end users over time. A fluid’s ability to maintain its viscosity over extended periods of time can allow end users to extend a hydraulic drain interval, lessening maintenance burdens and allowing operations to continue uninterrupted.

Advancements in efficiency

Viscosity retention was not the only performance characteristic Lubrizol’s testing team sought to validate in evaluating OCP’s potential impact on modern hydraulic fluid formulations. Because the need for greater energy efficiency has been the primary driver of design changes we have seen in hydraulic systems, we sought to demonstrate a performance polymer’s ability to contribute directly to new efficiency gains that can improve an end user’s bottom line.

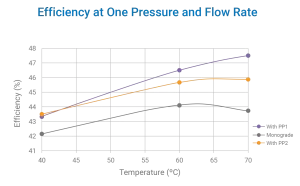

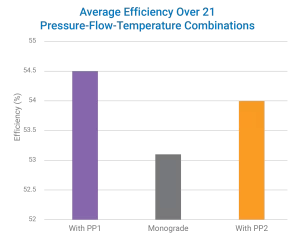

To evaluate potential efficiency gains, we introduced a conventional monograde fluid with no performance polymer as a baseline to our testing. The three experimental formulations were tested via controlled experiments within Lubrizol facilities and in off-site, climate-controlled laboratory settings, across a range of common hydraulic work cycles.

In each, PP1 demonstrated clear efficiency gains versus PP2 and the conventional monograde fluid. Testing was performed at consistent flows and pressures, and across numerous different pressure and flow combinations, in order to validate efficiency gains in a range of applications.

The OCP technology used in our PP1 fluid improves the fluid’s secondary flow properties, which helps create efficiency gains that are realized throughout the hydraulic system, outside of the pump. Secondary flow is where the hydraulic fluid is moving in a different direction to primary flow within an application. Secondary flow typically occurs when flow is constricted or changes direction within the hydraulic system. Secondary flow can thereby prevent the fluid from moving as effectively and efficiently as possible—OCP helps to mitigate this issue, thus directly contributing to improved efficiency. The efficiency benefits of the OCP polymer only grow in more complex systems, where more secondary flow events are likely to occur.

High-performance fluids matter

Modern hydraulic equipment has created new demands of hydraulic fluids, and it’s critical that such fluids remain up to the task. As demonstrated by Lubrizol’s testing, new additive and polymer chemistry has the potential to improve the essential protective characteristics of today’s fluids while providing new efficiency benefits.

For fluid formulators, it is worth exploring ways these technologies can improve formulations to best protect hydraulic equipment. For end users, selecting high-performance hydraulic fluids can deliver real-world benefits, helping to maximize the useful life of hydraulic equipment while minimizing maintenance requirements when such equipment is in service. Hydraulic equipment continues to play a critical role in the modern world, and maximizing its potential with the right fluids stands to benefit everyone. •