Research to Watch: Investigation of Noise Transmission through Pump Casing

This column will bring you the progress of the pre-competitive research being conducted at member universities that are part of the CCEFP network. This research will help give insight into the future direction of fluid power.

The Center for Compact and Efficient Fluid Power (CCEFP) holds a monthly forum, highlighting research, workforce, and special topic presentations.

CCEFP is a network of fluid-power-research laboratories, academic faculty, graduate and undergraduate students at nine universities. It is also a National Science Foundation Research Center. For more information on CCEFP, visit www.ccefp.org.

Since 2014, the National Fluid Power Association (NFPA) Foundation has supported and is helping to expand the pre-competitive fluid-power-research activities of the CCEFP, dramatically increasing the number of institutions and students impacted by its research program. For more on NFPA, visit www.nfpa.com/aboutnfpa/missionfocus.aspx.

Research Assistant: Dan Ding, a Master’s student at Purdue University

Project Leader: Dr. Monika Ivantysynova, Professor Agricultural & Biological Engineering/Mechanical Eng

Institution: Purdue University

PURPOSE

The goal of this research is to model the transmission of vibrations from a swash plate type axial piston pump through the pump’s casing to the generation of acoustic noise in the surrounding environment. The desired result of this research is to gain a better understanding of noise generation and transmission in axial piston pumps and to create a comprehensive model of an axial piston pump’s noise emission. This computer- based model can be used for the predictive design of pumps, including pump housing and valve-plate design to reduce airborne noise generation.

PROGRESS

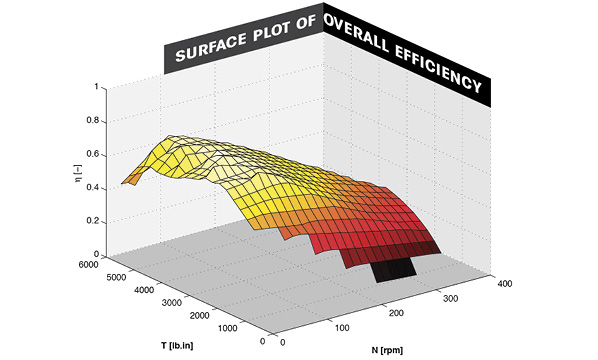

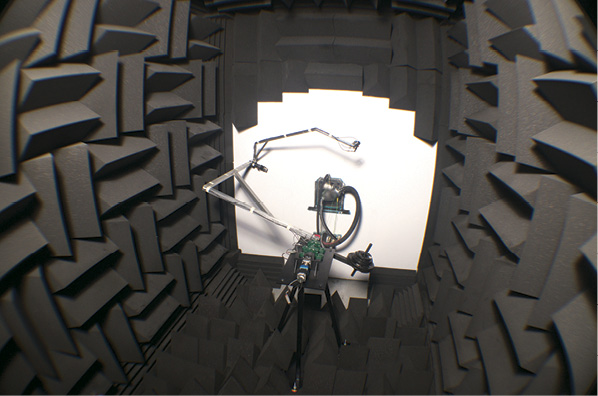

Using a generic structural acoustic process, a pump’s oscillatory energy was organized into three domains—hydraulic, vibration, and acoustic—and a task was formulated for each domain. Task 1 (hydraulic) was to measure pressures to validate the current hydraulic model, task 2 (vibration) was to preliminarily perform experimental modal analysis, and task 3 (acoustic) was to experimentally characterize the sound field using a custom made robot. So far, the experimental results have supported that pump harmonic frequencies below 5,000 Hz are the dominant frequencies of audible noise. To better interpret the spatial distribution of noise, it was decided to minimize the reflection of pressure waves by covering the expose concrete floor in the semi-anechoic chamber. Additionally, a new hemispherical measurement grid was created in order to take advantage of its geometric symmetry that required new robot speed and a taller robot stand. Major improvements were also made to the sound chamber in order to raise the shaft height and improve the acoustic qualities. The modelling method is being revisited, and custom-vibration modelling software is being developed.

NEXT STEPS

The remodeling of the sound chamber will be completed, and the experimental modal analysis will continue.