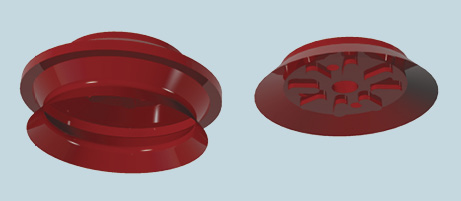

Basic Vacuum Cup Selection: Part 1

There are many types of vacuum cups available from a large range of manufacturers. The primary application of vacuum cups is on automated machinery, such as …

Turn It Off!

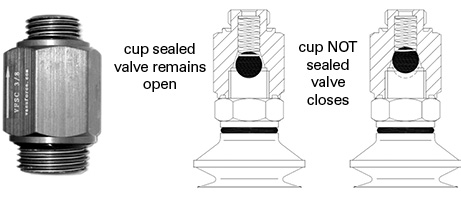

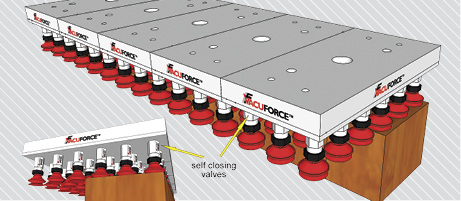

If it’s not needed, then don’t use it, right? An obvious statement, but so rarely is this philosophy employed when using compressed air-powered venturi …

Hold It Down

Most of my previous articles have been about vacuum pick-and-place, which is the most common application in fluid power circles for vacuum components. However, …

Safety First!

Select a Secure Circuit Design In fluid power applications, safety is the number-one priority in the design of a system. Vacuum lifting, as you can imagine, is …

Random Pick and Place

In 90% of vacuum pick-and-place applications, the product being handled is a known size, shape, and weight. A packaging machine designed to pick up a 20-lb box …

The Pressure Is On!

Most industrial vacuum applications involve the picking up or transfer of products, such as vacuum pick-and-place or material conveying. This article discusses …

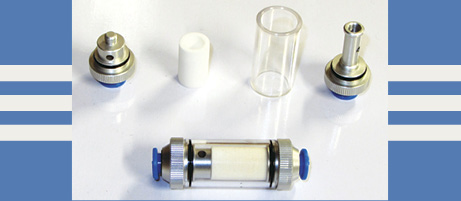

Vacuum Filters

I have previously written about the importance of filtration in vacuum pick-and-place applications and in other tasks where dirt and dust might be present. …

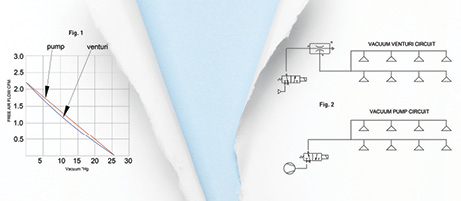

Pump or Venturi?

When a salesperson is quoting a vacuum installation, a common question to the end user is, “Would you prefer a vacuum pump or venturi?” More often …

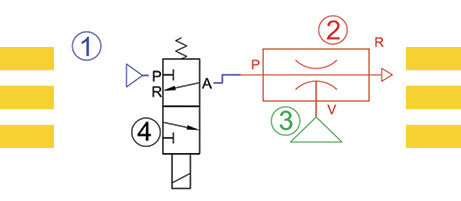

Basic Vacuum Schematics

In vacuum material handling, there usually are only a handful of separate components, such as a vacuum pump, inlet filter, control valves, and cups. This …

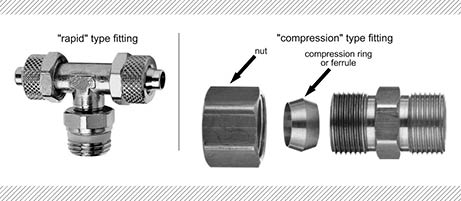

Vacuum Hose and Fittings

Most applications involving vacuum pick-and-place components utilize small-diameter hose and tubing—the same hose and tubing used on similar-sized pneumatic …