Test Your Skills

Each month Fluid Power Journal brings you an industry problem with a solution the following month.

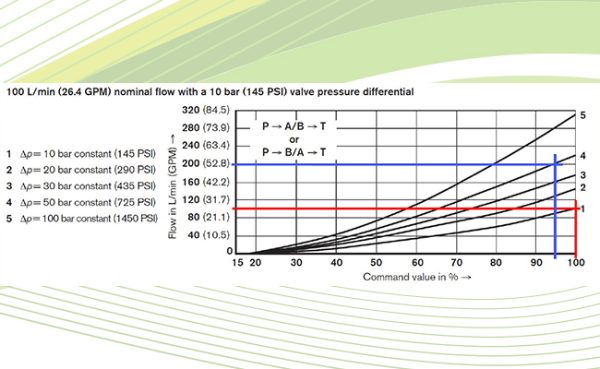

Test Your Skills: Application of Proportional Valves

There are many applications for proportional solenoids in the control of hydraulic pressure and flow in both mobile and industrial applications. The terms …

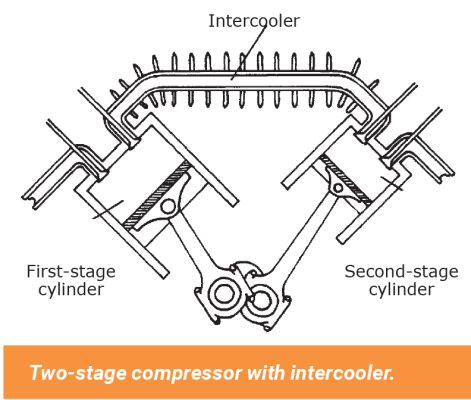

Test Your Skills: Types and Applications of Compressors

The generic term “supply side” is often used to refer to the complete package that includes the compressor, drive motor, and associated hardware, as well …

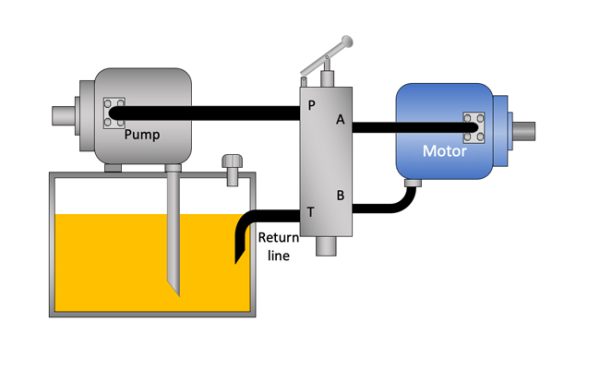

Test Your Skills: Hydrostatic Transmissions

The transmission of force through a contained hydraulic fluid (hydrostatics) will fall into one of two categories: open circuit or closed circuit. An open …

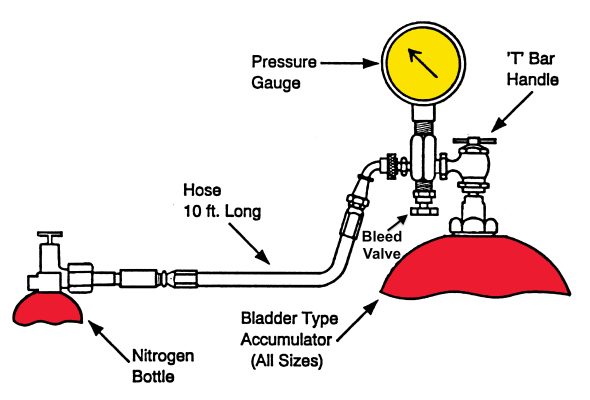

Gas-Charged Hydraulic Accumulators

Accumulators are pressure vessels and are subject to the American Society of Testing Materials standards in addition to the International Standards …

Stopping a Load with a Shock Absorber

It is common practice to position shock absorbers to cushion loads attached to air cylinders, rather than to subject the air cylinders to shock loading …

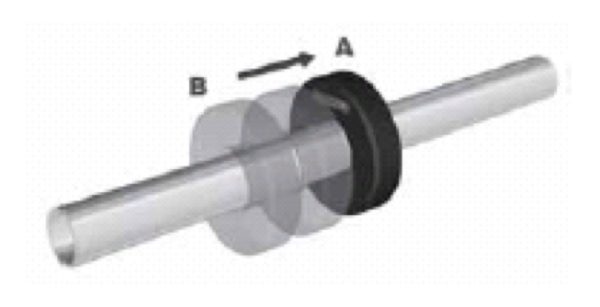

Recognizing Misaligned Cylinders

Misalignment of a cylinder occurs when the load is not applied along the centerline of the rod. Many applications have a small amount of inherent misalignment …

Linear Displacement Sensors

The first factors to consider when selecting linear displacement sensors are the mechanical interface, dimensions, contact, noncontact, and environmental …

Selecting Vacuum Pads

Vacuum pads are primarily used for handling smooth surfaced material but can be used with textured or irregular shaped material as well. Because sheet glass …

The Function of Fluids

The word “fluid” refers to something that flows and can describe a gas or a liquid. A hydraulic system is the transmission of power by means of a …

Understanding Supply-Side Air Preparation

As air is compressed, the temperature of the air increases significantly. The compressor discharge air temperature is typically over 200°F (93°C) for a …