Air Teaser: Find the Cylinder Rod

By Ernie Parker, CFPAI, CFPSD, CFPS, CFPMM, CFPMT, CFPMIP, CFPMMH, CFPMIH, CFPE.

What is the maximum theotretical efficiency for extension and retraction?

How many standard cubic feet per minute are wasted?

What is the cost of the wasted air for a year at $.50 per 1,000 standard cubic feet working 24/7?

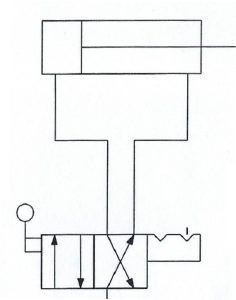

1″ x 6″ x 5/8″ (25.4 mm x 152.4 mm x 15.875 mm) cylinder

Extend and hold 2 seconds

Retract and hold 2 seconds

Dwell 6 seconds

Load 39.27 lbs.,

174.67 N extend force

0 load on retract

Hoses are 1/4″ x 10′

(3.05 meters) long

See the Solution

What is the maximum efficiency for extension and retraction?

To extend the cylinder, it takes 50 psi (3.45 bar).

Compression ratio (CR) at 100 psi = (100 + 14.7) / 14.7 = 7.8

CR at 50 psi = (50 +14.7)/14.7 = 4.4

Solving: Area of cylinder x stroke x cycles/minute (cpm) x CR / 1,728 = scfm (1,728 = cubic inches in a cubic foot)

Volume of cylinder given to extend at 100 psi is 1² x .7854 x 6 x 6 cpm x 7.8 / 1,728 = .128 scfm

Volume of cylinder needed to extend at 50 psi is 1² x .7854 x 6 x 6 cpm x 4.4 /1,728 = .072 scfm

Loss energy in cylinder because only 50 psi is needed = .1276 – .072 = .055 scfm

Loss in 1 hose = .25² x .7854 x 120” x 6 cpm x 7.8 CR / 1,728 x = .160 scfm

Total loss energy to extend (cylinder + hose) = .055 + .160 = .215 scfm

Total energy used = .128 + .160 = .288 scfm

Efficiency = .072 / .215 = 33% for extension

To retract the cylinder, it theoretically takes no pressure.

CR = 7.8

Solving: Rod-end area of cylinder x stroke x cpm x CR / 1,728 = scfm

Volume of cylinder to retract = (1² x .7854) – (.625² x .7854) x 6” x 6 cpm x 7.8 CR/ 1,728 = .078 scfm

Loss in 1 hose = .25² x .7854 x 120” x 6 cpm x 7.8 CR / 1,728 x = .160 scfm

Total energy loss = .078 + .16 = .238 scfm

Total energy used = .078 + .16 = .238 scfm

Efficiency 0 / .238 = 0% for retraction

Note: It isn’t reality to use no pressure to move an empty cylinder.

Total loss scfm = .215 + .238 = .453 scfm wasted

Cost = .453 x 60 minutes x 24 hours x 365 days x $.50 / 1000 = $119.05 Cost for wasted air

Total loss in air hoses = .16 x 2 hoses x 60 x 24 x 365 x .50 / 1,000 = $84

Almost $84 per year could be saved by just moving the valve close to the cylinder, and you wouldn’t have the air loss in the hoses since the air never enters the cylinder. Additional savings could also be made by using an air regulator on the rod end of the cylinder to reduce the air pressure that isn’t needed.