Building the World’s First Fully Electric Large Foundation Rig

Pioneering Sustainability in Construction

By Stefan Eichler, Senior Manager Editron Sales EMEA, Danfoss Power Solutions.

Construction machines worldwide emit a staggering 400 MT of carbon dioxide annually, equivalent to the yearly emissions generated by international aviation. For construction sites to decarbonize and reach emissions reduction targets, construction machines must evolve.

When Hydrauvision, a leader in hydraulic and electrical drive and control solutions and parent company of foundation rig specialist Fundex Equipment, decided it wanted to help drive the construction industry’s sustainable transition, it decided to electrify a foundation rig in a world-first project.

While some construction equipment is fairly easy to electrify due to the relatively low energy required, building a large, fully electric foundation rig had yet to be achieved until Hydrauvision took up this challenge. The company needed to develop an innovative approach to power supply to ensure a large foundation machine stayed running throughout the working day.

Flexible design for the future of energy

The F4800E is based on Fundex Equipment’s diesel-powered F4800 foundation rig, which has a 500 kNm (368,761 lbf.ft) full-length drilling torque and a daily energy consumption of up to 2,000 kWh (1,490 hph). With a leader length of 48 meters (157 feet), the electrification of foundation machines of this size is unprecedented, making the powering of the machine the primary challenge.

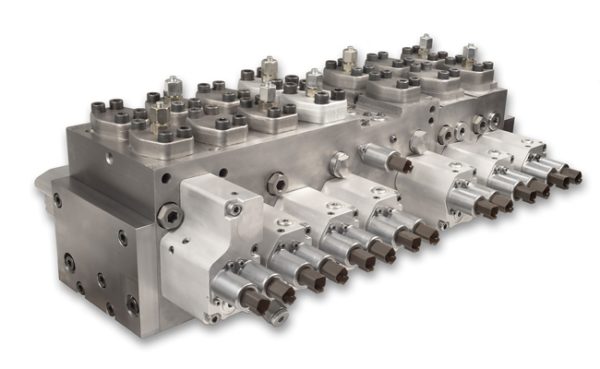

To make the machine compatible with most construction sites, Fundex decided to prioritize flexible design and give the new F4800E the ability to switch between different energy sources. As a result, the basic machine, including winches and hydraulic pump units, is entirely electrically driven by permanent magnet machines and drive converters supplied by Danfoss. The F4800E also features a 150 kWh (112 hph) integrated battery pack for peak shaving during regular operation. In addition, the battery is used to store regenerated energy from the winches. This means the machine can operate totally emissions-free when connected to a power source.

However, power sources are not yet available on every construction site. Therefore, Hydrauvision developed a new DC-generator set with a diesel engine to supplement the battery pack on the basic F4800E machine and prevent inefficient peak loads, with peak shaving as a power backup. This configuration maintains the machine’s sustainability benefits by reducing energy consumption by 25% to 40%, depending on the foundation process.

Another issue currently facing the construction industry is uncertainty around what the primary energy source for producing and storing electricity will be in the future. To account for this, the generator set can easily be disconnected and replaced with various energy sources, such as hydrogen, formic acid, or e-methanol. The system can also be connected directly to the electric grid. Therefore, as soon as other energy sources become available, Hydrauvision can respond to them very quickly due to the flexible design of the F4800E. This gives customers a high return on investment.

Another issue currently facing the construction industry is uncertainty around what the primary energy source for producing and storing electricity will be in the future. To account for this, the generator set can easily be disconnected and replaced with various energy sources, such as hydrogen, formic acid, or e-methanol. The system can also be connected directly to the electric grid. Therefore, as soon as other energy sources become available, Hydrauvision can respond to them very quickly due to the flexible design of the F4800E. This gives customers a high return on investment.

High performance to match conventional foundation rigs

Aside from the substantial sustainability benefits, Hydrauvision also prioritized high performance in the design of the F4800E. By basing the design on the conventional machine, though replacing the diesel powertrain with a fully electric system, they were able to maintain and, in places, enhance performance.

The F4800E is specially designed for both drilling and pile driving techniques. Production performance is also equal to that of conventional machines, including a high drill torque of 500 kNm (368,761 lbf.ft) along the entire leader length and a maximum 1333 kN (150-ton) pull-up force and 356 kN (40-ton) tool weight.

The F4800E’s controls are identical to the conventional machine’s, meaning operators can easily transition to the electric rig. Due to its electric motor, the machine also provides a 90% noise reduction during operation compared to a diesel-driven rig, which is a valuable advantage when working in urban environments.

One step closer to a more sustainable construction industry

One step closer to a more sustainable construction industry

The result of Danfoss Editron’s collaboration with Hydrauvision and Fundex Equipment is the first fully electric large foundation rig on the market. The rig’s performance was tested in September 2023 when it successfully completed its first commercial project in Rotterdam for the real estate and construction services business Heijmans.

While operating on the Canvas Living residential building project in Rotterdam, the F4800E successfully installed over 250 foundation piles. A conventional F3500 foundation rig was used on the same project as a point of comparison for the electric rig. Powered by Hydrauvision’s electric powertrain system and DC-generator set with a diesel engine, the F4800E proved to be a strong, robust, and reliable machine that can match the performance of conventional rigs.