Calculate Cylinder Size For Pneumatic Door Openers

By Ernie Parker, CFPAI, CFPSD, CFPS, CFPMM, CFPMT, CFPMIP, CFPMMH, CFPMIH, CFPE.

Most of the handicap doors are operated with linear actuators, however there is a much cheaper solution using pneumatics. I installed three pneumatic door openers in a church for a total of $700 that included an air compressor and handicap buttons. As I was connecting the last line, a minister walked in and told me that they just spent $14,000 for one door at a different church.

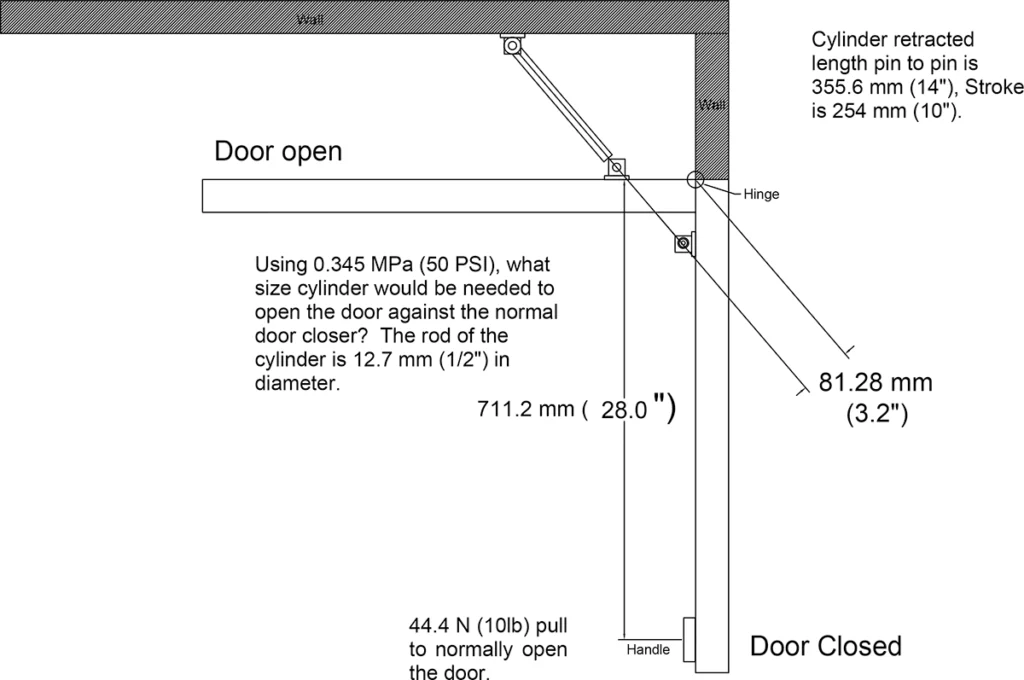

I approached the opportunity using pneumatics with a cylinder for each door that would retract when someone pushed the handicap button. The buttons have a built-in time delay making the installation very easy. I purchased a small air compressor and mounted it in a maintenance room and connected a small drain line to the bottom of the tank with a shutoff valve to drain the water occasionally. Additionally, I added a pressure regulator and the two position, three-way directional control valves connecting to the cylinders. The exact placement of the cylinders was done on AutoCAD so that the door would completely open or close at the end of the stroke.

Here is the beauty of using pneumatics. First the regulator limits the force that opens the door. If the door is locked, nothing moves and nothing breaks. If something like someone’s cane or foot gets in the way, it just stops and doesn’t burn out a motor or damage anything. The big handicap buttons are placed about waist high where people walking in with their hands full, can easily push them with any part or their body. Secondly, there isn’t any additional force required to close the door; that is done with the original door closer, so there is no additional liability. Third, I like the fact that, when the door is opened manually, there is no additional effort like the electric ones require. I did run a line from the cap end of the cylinder back inside the building with a filter/muffler on it.

Problem: Using the attached drawing, calculate the standard size pneumatic cylinders that are needed to open the doors. The cylinders retract to open the door.

See Solution

Find the moment (torque) required to open the door and then the pull force of the cylinder.

Metric:

44.4 N × 711.2 mm to the pivot = 31577.28 Nm.

Then divide by the perpendicular distance from the same pivot (hinge).

31,577.28 Nm/ 81.28 mm = 388.5 N.

F = PA

388.5 N / .345 MPa = 1126 mm² needed.

Now add the area of the rod.

12.7² × 0.7854 = 126.68 mm².

Adding the required area and the rod area is

1126 + 126.68 = 1252.77 mm².

Working backwards to find the diameter;

1252.77 mm / .7854 = 1595; √1595 = 39.94 mm.

The next standard size up would be a 50 mm, requiring less pressure.

US Customary:

28” × 10 lb = 280 lb.in. / 3.2” = 87.5 lbs.

F = PA

87.5 lbs / 50 psi = 1.75 in².

Now add the area of the rod. 0.5² × 0.7854 = 0.19635 in².

Adding 1.75 in² + 0.19635 in² = 1.95 in².

Find the diameter working backwards using the formula

A = D² × 0.7854.

1.95 / 0.7854 = 2.48 and taking the √2.48 = 1.57”

The next standard size up would be a 2-inch cylinder, requiring less pressure.

Checking your answers 1.57” × 25.4 = 39.9 mm,

the same as the metric answer.