Cleanova re-imagines O&M Filtration support with launch of Cleanova.CARE

Cleanova.CARE is a new comprehensive suite of services designed to optimise filtration systems

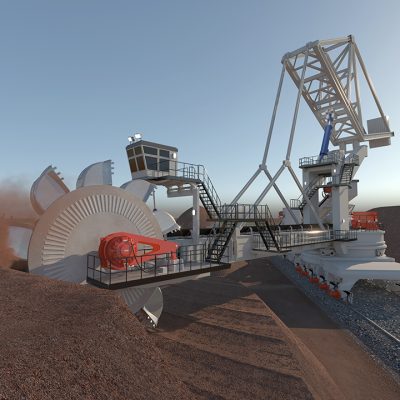

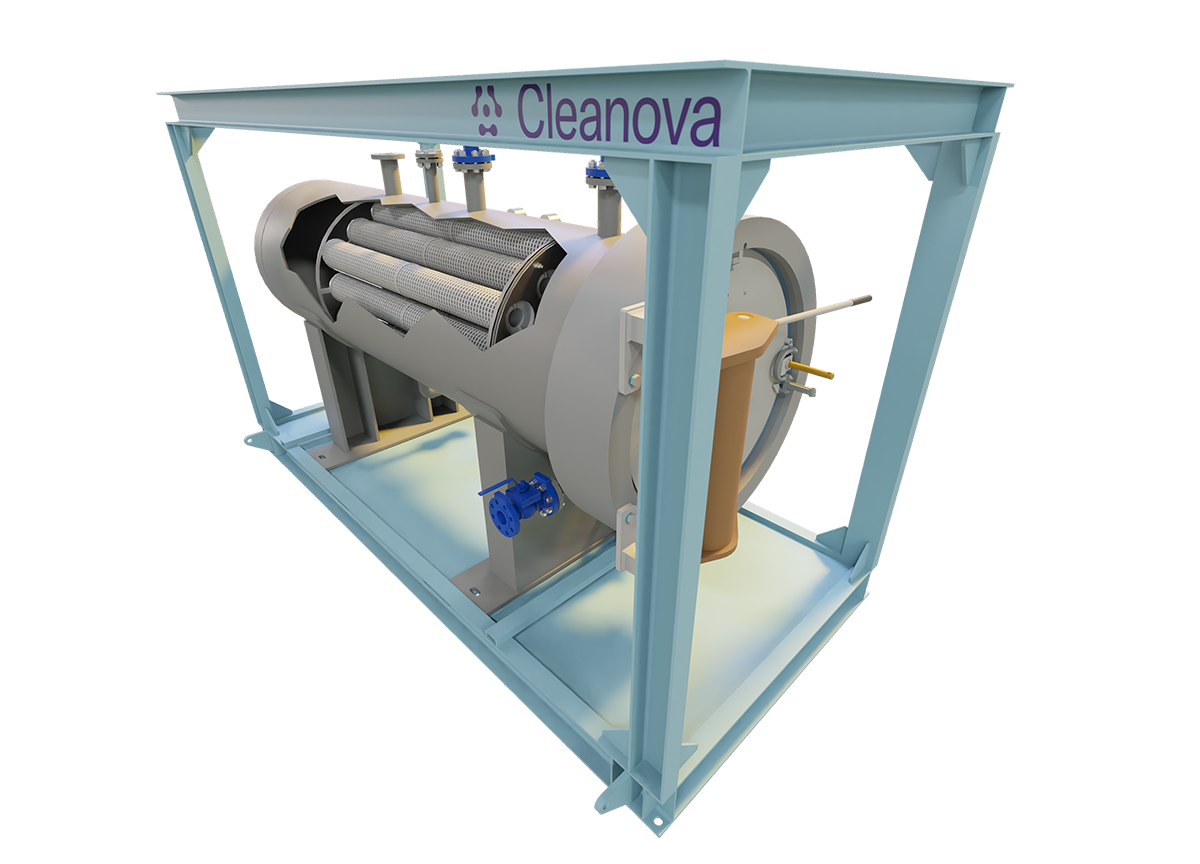

Incorporated into Cleanova.CARE FAST units, UNIQ-MAX high-capacity filters can help identify and resolve high solids loading issues

3 September 2024 – What makes it difficult for operations and maintenance managers to keep industrial filtration systems running efficiently over time? This question was the starting point for the evolution of Cleanova.CARE, a new and comprehensive approach to filtration support from Cleanova, which owns established filtration brands Airpel, Dollinger, Plenty and Vokes.

Cleanova.CARE encompasses a comprehensive suite of services that include on-site testing, aftermarket spares, rental rigs and expert support with capital upgrades: but these are secondary to Cleanova’s primary purpose, which is to work collaboratively with customers to achieve the best possible filtration outcome.

As a relatively new entrant in the industrial filtration sector, Cleanova is not afraid to challenge expectations. The company has already pledged to eradicate tortuous transactional routes from its business so it can forge long and lasting relationships with customers.

Cleanova.CARE encompasses five key support pillars:

FAST solutions that range from on-site technical support and recommendations to optimise operations and maintenance to the sourcing of aftermarket spares.

FAST filter testing to determine the quantity and type of contaminants in the process and measure the effectiveness of current filtration systems, without the need to halt production.

FAST units that give customers the flexibility to bypass current processes, maintain continuous operation, or trial alternative filtration options without high capital expenditure.

FAST exchange to assist customers in finding the best value, best quality filter replacements without paying premium OEM prices, to reduce the total cost of ownership.

FAST recovery is a prompt and cost-effective means of reconditioning sewn-end filter elements with specially formulated filter media at a fraction of the cost of buying new. Recycling the metal frames also reduces waste to make filter replacement more sustainable.

Chris Nixon concludes: “Cleanova.CARE enables us to deliver outstanding results by responding quickly, engaging in technical discussion or site investigation to get to the root of the customer’s filtration challenge, and providing a lasting solution that minimises cost, maximises uptime, and optimises efficiency.”

For more information, visit: cleanova.com/cleanovacare