Compact Hydraulics Is on the Move

By Ben Dupré, Sr. Technical Writer, HydraForce, Inc.

In today’s world, where innovation, sustainability and digitization are at the heart of new solutions, Bosch Rexroth Compact Hydraulics is responding to the needs of mobile machinery manufacturers with increasingly sustainable and smart solutions. For instance, the use of energy efficient hydraulic components is becoming more common to reduce fuel consumption and harmful emissions. Additionally, the integration of digital technologies such as sensors, actuators, and intelligent control systems is improving the precision and responsiveness of hydraulic systems, enabling manufacturers to achieve fast response times and greater system reliability.

Another emerging trend is the use of compact and modular hydraulic solutions, which allow manufacturers to design more compact and lightweight machinery, thus optimizing resources and improving maneuverability and operator comfort. The response to the new needs of mobile machinery manufacturers is taking place through innovation, sustainability, and digitization, which are leading to increasingly efficient, precise, and compact solutions.

The new EDG-OBE

Today Bosch Rexroth is developing a new closed-loop piloting module with onboard electronics for the EDG line of pre-compensated compact directional valves. The EDG-OBE joins EDG-DP direct-operated, and EDG-PP pilot-operated analog open-loop products. The wide scalability and extensibility with functions like anti-shock, anti-cavitation, LS relief and many others complement the flexibility and configurability of this product family.

EDG-OBE features closed-loop operation with integrated spool position feedback. This allows the onboard controller to continuously adjust piloting forces to maintain a desired spool position. Closed-loop control can reduce deadband and hysteresis, while also optimizing step response, compensating for hydrodynamic forces, and self-linearizing the control curve. In a closed-loop system, the valve simply does what you ask of it. This dramatic increase in accuracy opens the door to all sorts of precision applications, including autonomous vehicle functions.

Distribute control for flexibility and efficiency

The EDG-OBE is a plug-and-play CAN control compatible with the SAE J1939 standard used primarily in mobile machinery applications. It can be added easily to any vehicle with a Controller Area Network. As an independent CAN device on the network, the main vehicle control needs only to send a command telling the valve to open at some percentage of maximum. The onboard electronics do the rest. The OBE is also able to send messages back to the vehicle controller, reporting status, opening position, and diagnostic messages (DMs).

The OBE handles all the functions needed to provide a stable output from the valve. It operates the PID control loop and allows very precise tuning for the needs of a particular application. It controls the piloting of the main spool, adjusting forces many times per second to maintain the provided setpoint.

Using CAN to employ distributed control lightens the load on the main vehicle controller allowing you to use a more economical main vehicle control with less total I/O. A distributed control architecture can even allow multiple independent controllers to operate the EDG-OBE. For example: a truck-mounted crane may have a vehicle mounted control station and a remote “belly box” control. A mobile elevating work platform typically employs ground controls and platform controls. These separate control stations can operate the valves independently, and the long wire loom to the platform only needs to carry a low-voltage CAN signal, not heavy current-carrying conductors with a large voltage-drop. An application may even include redundant controls for safety reasons.

Close the loop on hysteresis

Closing the loop with spool position feedback has many benefits and allows the EDG-OBE to self-compensate for variations such as coil resistance, temperature, and hydrodynamic forces. Even manufacturing variation is overcome with position feedback. The net effect is accuracy approaching that of very expensive servo-controls, faster response, and very low hysteresis.

Optimize your controls for the needs of each function

The PID control loop is tunable to optimize for different performance needs. One function on the machine may require very fast operation while another may be intolerant of overshoot. With closed-loop control, you can also change the response of the control to match the actuator. One function may require a wide deadband while another may require a quick response at the beginning of the stroke, and a slow response near the end. With EDG-OBE each section can be tuned and shaped independently. You also have the traditional options available such as optimizing the metering profile though the use of alternative spool configurations.

With software you can perform Input/output scaling and curve shaping, and with closed-loop control you can do this very accurately. Imagine you have a section of the valve bank dedicated to controlling attachments, possibly used with an ISOBus display/controller: the control curve and performance can be adapted to the different needs of each attachment without any hardware change required. Or an operator of a mobile elevating work platform must position the boom very carefully around electrical transmission wires, you can design a creep mode that slows the boom movement for precise placement.

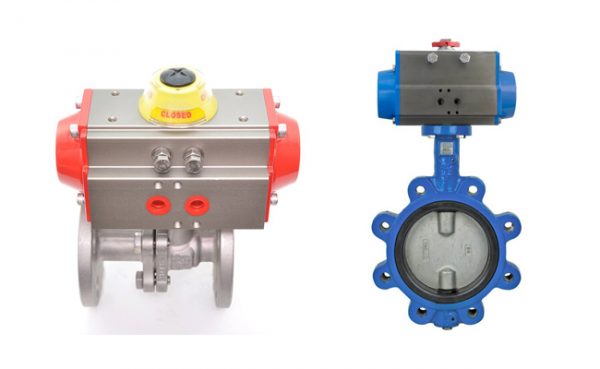

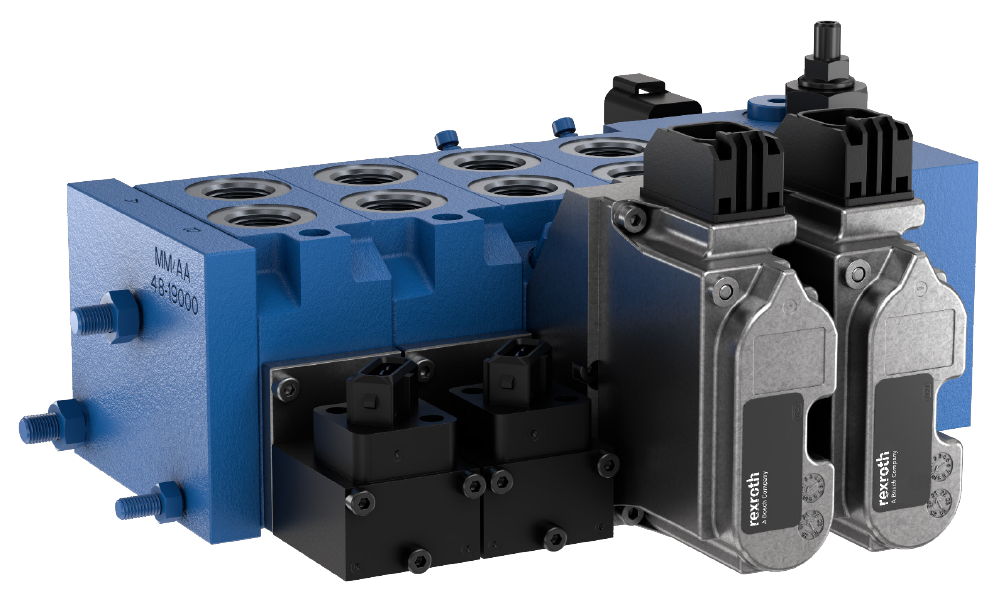

Four function valve bank with EDG-PP (left) and EDG-OBE (right) modules.

Operate safely

With failover-redundant control circuits, EDG-OBE is Pld (Performance level d) compliant as per ISO 13849 making it suitable for use in applications such as mobile elevating work platforms and truck-mounted cranes where operator safety concerns demand a very high level of reliability.

The on-board electronics are compatible with CANsafe networks for use on machines with elevated safety and security concerns. CANsafe is an extension of the Controller Area Network (CAN) protocol designed for use in applications where safety is of paramount importance. CANsafe adds a number of features such as: error detection and reporting, fault tolerance, diagnostics, and encryption to CAN that make it more suitable for safety-critical applications.

Save space

With smaller more efficient machines being developed today, space claim can be an important factor when choosing hydraulic system components. The EDG line of bankable compact directional valves is the most compact and lightweight solution available in the industry for flow rates up to 60 lpm (15 gpm).

Save energy

The EDG-OBE uses smart energy control. Compared to electrohydraulic piloted control EDG-PP, the OBE piloting element consumes less power while holding spool position. On battery-powered vehicles, every amp counts, and even small

Build flexibly

Bosch Rexroth compact directional valves are very modular and scalable in nature. You can mix and match valve sections to build your entire hydraulic system in one unit. In addition to EDG-OBE, the EDG line of 4/3 and 4/2 pre-compensated, bankable spool valves has on-off modules (EDG-DO), direct-acting proportional modules (EDG-DP), and electro-hydraulically piloted proportional modules (EDG-PP) that can be combined in one bank. All of these are customizable with various port-relief, anti-cavitation, counterbalance, PO checks, and load-sense relief valves. Additionally, dedicated inlet or intermediate elements are available to adapt other frame sizes to form a complete hydraulic solution for any flow rate.

Depend on precision

Responding to the demand for more autonomous machines and machine functions, closed-loop control is becoming a key component in many applications. The enhanced precision and reliability these controls provide are essential for functions like automatic steering on machines that track a repetitive course. Whether plowing a field or grading a building site, any error in the hydraulic steering can quickly compound as the vehicle moves row by row across the field/site.

Material handlers that place bulky pallets precisely in high storage bays rely heavily on the accuracy and repeatability of closed-loop controls. As every cubic foot of material storage space is maximized, the empty spaces between pallets and cartons shrink. The technology is essential to performing material movements safely as warehouse space is often shared with inventory workers and even big-box retail customers.

Truck-mounted cranes may unload cargo onto the street, or may be expected to place building materials precisely on upper stories and rooftops. Mobile elevating work platforms require greater precision in their controls when operating while the platform is in the air. Both types of machines employ long booms that can store kinetic energy and may become wildly unstable if not carefully controlled.

Align your vision

Bosch Rexroth is committed to providing powerful compact solutions for your mobile equipment that stretch the market’s expectations. In a world that is rapidly moving to maximize sustainability and energy efficiency, hydraulics continue not only to remain relevant, but also to provide the most optimized solutions where power density and compactness are a major concern.

HydraForce cartridge valves and electronic controls have recently been added to the compact hydraulics family. As ONE company, HydraForce and Bosch Rexroth Compact Hydraulics are already strongly aligned with a vision for the future of hydraulic controls.