Endress+Hauser Adds to Proline Promass Q Flowmeter Lineup

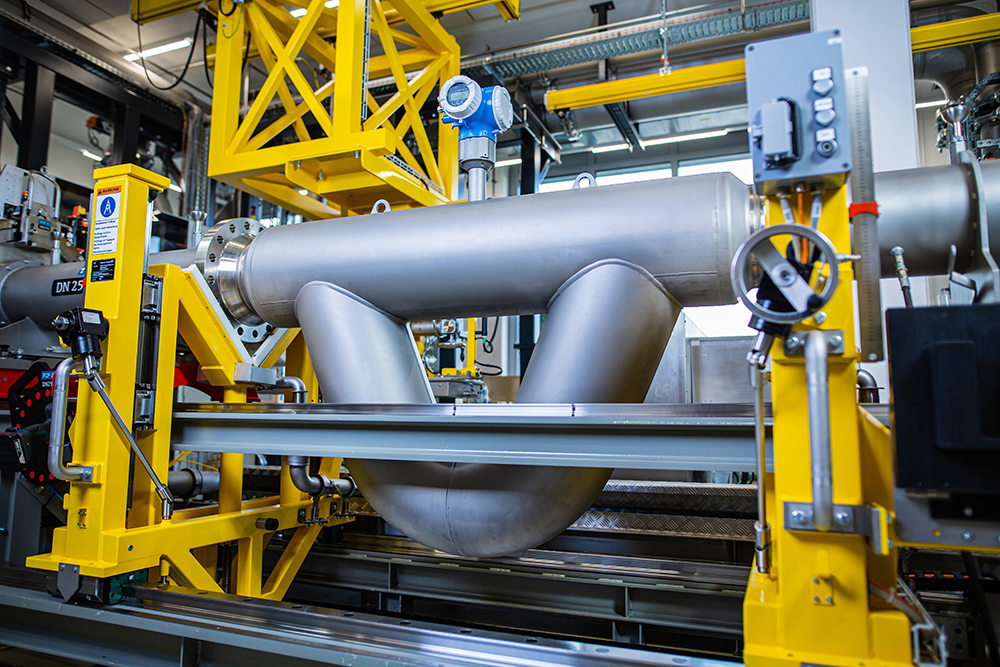

Endress+Hauser recently added to its Promass Q lineup, which is now available for larger pipes, up to 10” (DN 250), for measuring flow rates up to 18,900 bph (2,400 t/h). And the new four-tube technology opens the door to additional applications in the oil and gas industry. These include high-precision metering for custody transfer, fiscal metering, master metering as a reference device for on-site verification, and more.

In addition to mass and volumetric flow, Promass Q also records process density and temperature. This enables the incorporation of fluctuating process and ambient conditions into flow measurement, with appropriate compensation, helping achieve tight error bands of ±0.05% for mass flow and ±0.2 kg/m³ for density.

Four-tube technology pushes the boundary for Coriolis flowmeters. Compared to meters with two measuring tubes, four tubes reliably measure 25% greater flow rates, enabling faster transactions in the oil and gas business. Four-tube technology reduces pressure loss while pumping and measuring because of the increased cross-sectional flow area relative to line size. This provides further cost savings because operators can use smaller pumps, which consume less energy relative to overall volumetric output.

Promass Q flowmeters are available in stainless steel and IP66/67-rated materials, ensuring robust and long-term operation, even in harsh conditions, such as offshore areas with high humidity and salt spray. Promass Q is rated for process temperatures ranging from –321°F to 401°F (–196°C to 205°C), with the low-end making Promass Q meters an ideal choice for measuring cryogenic fluids. With SIL ratings in compliance with IEC 61508, Promass Q is also suitable for safety-related applications.

For more information, visit www.us.endress.com.