Festo Launches Essentials Customer-Service Program

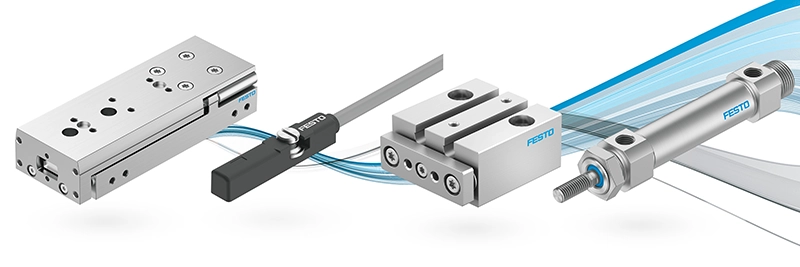

Festo recently launched its pneumatic Essentials program, an ambitious global undertaking to streamline ordering, ensure fast delivery of guaranteed in-stock pneumatic components, and produce more compact parts for today’s smaller-footprint, energy-efficient machines.

In addition to competitive prices, guaranteed availability, short delivery time, and innovative design, customers are assured of world-renowned Festo quality components that boost machine performance, lower waste, and reduce the risk of downtime.

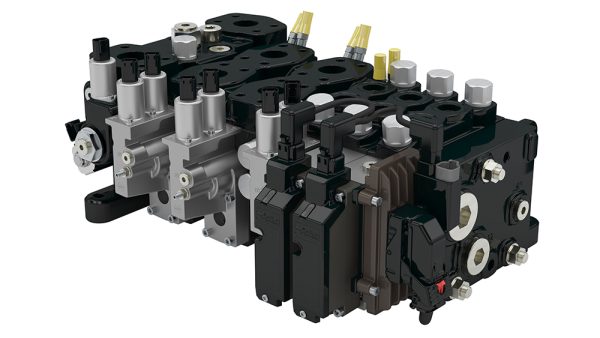

Pneumatic Essentials is a one-stop-shop for the 16 fundamental components that Festo finds fit most common pneumatic applications. These components include air preparation, high wear polyurethane tubing, one-way flow control valve, high-flow valves for normal and harsh environments, self-teaching proximity switch, mini slide, guided drive, direct interchangeability ANSI NFPA cylinders, and metric and imperial round and compact cylinders.

North American customers will experience short delivery times for both catalog and customized Essentials components from the Festo Global Production Center in Mason, Ohio. Quick, assured Essentials shipping is available to customers globally from Festo regional service centers. Global availability is an inventory and uptime plus for original equipment manufacturers and end users, as they are assured of rapid receipt of replacement parts.

Festo invested substantial time, energy, and resources in augmenting manufacturing and logistics to ensure a robust supply chain for pneumatic Essentials.

For more information, visit here and www.festo.com/us/en/.