How to Protect and Optimize Pressure Transducers on Mobile Hydraulics

By Mark Zabawa, Ashcroft’s Director of North America OEM/Direct Sales.

Hydraulic machinery exceeds nearly every other mechanical form of power transmission when working in extreme environments. Excavators, tree harvesters, mining, tow trucks, and other hydraulic vehicles perform the harshest tasks on uneven terrains with heavy loads that apply tremendous forces to hydraulic systems.

These tasks can generate extreme shock, vibrations, and dramatic temperature, dust, and moisture changes. In addition, pressure spikes/impulses generated within hydraulic systems can present a significant challenge to the reliability of internal components like pressure instruments.

So, how can you optimize the performance of your mobile hydraulics against hazards?

This article will help you with pressure control and measurement challenges, including shock, vibration, pressure spikes, pulsation, and environment. It will show you how to keep your mobile hydraulic machines in optimal shape.

Shock, Vibration and Spikes in Hydraulic Applications

Shock, vibration, pressure spikes, and pulsation can all challenge the pressure transducers in your mobile hydraulics equipment.

Hydraulic shock occurs when something causes the fluid to suddenly start, stop, or change direction. The impact of this shock affects any equipment in contact with the fluid. Your pressure instrument must be able to withstand the physical impact.

Short frequency/high amplitude pulses impact many instruments. Unlike air, hydraulic fluid has limited compressibility and pressure spikes in the system can increase four to five times over the normal operating pressure. That affects the performance and lifespan of pressure instruments if they are not strategically designed and protected.

Vibration is a mechanical oscillation that occurs occasionally or indiscriminately from motors, pumps, actuators, valves, hydraulic lines, and other components. It can generate flow ripples, which connect with hydraulic components such as transmission lines and valves to create harmonic pressure waves. Hydraulic vibration is primarily high frequency/low amplitude pulses that also affect the performance and lifespan of pressure instruments if they have not been designed to handle them.

Pressure Impulses (or pressure spikes) can also occur in hydraulic systems when fluid flow rates change quickly. Like a water hammer, a sudden valve closing can cause a significant short-duration, high-magnitude pressure wave within the hydraulic system. These pressure spikes are measured in microseconds but peak at many times the normal operating pressure.

Pressure Transducers in Mobile Hydraulics

Pressure transducers can be damaged under the continuous operation of pressure spikes and pulsation. The typical effect of pressure spikes and pulsation is a positive zero shift. Depending on the application, there are several choices to protect transducers, such as throttle screws, snubbers, and capillary lines.

Therefore, pressure transducers intended for mobile hydraulic applications must have compact sensing elements, shorter wire bonds, a coplanar design, and a small footprint to withstand shock and vibration.

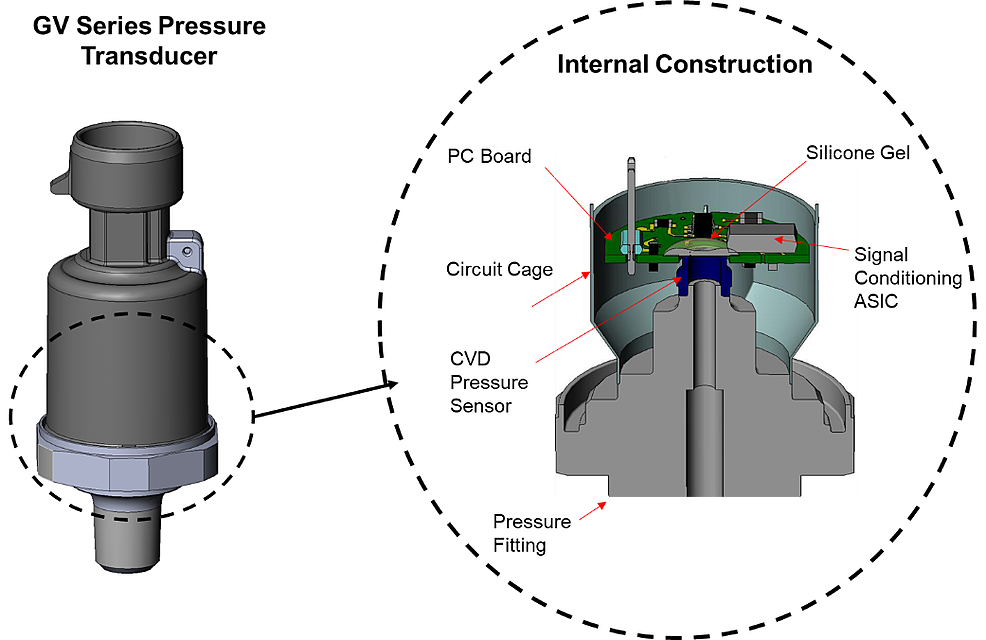

Ashcroft developed our CVD thin film pressure sensor with high stability, accuracy, and wide operating temperature ranges to meet the above requirements. In addition, we use a silicone gel that absorbs shock and vibration to protect delicate wire bonds, which connect the sensor element to the electronics. Figure 1 shows the Ashcroft GV pressure transducer enhanced design for vibration and shock application.

Figure 1- Ashcroft GV Pressure Transducer with enhanced Vibration and Shock Protection

The Ashcroft® S1 OEM pressure transducer is another good option. It incorporates the CVD sensing technology to provide a cost-effective transducer that provides superior performance. The S1 is a hydraulic pressure sensor designed for applications that see high shock, vibration and excessive pressure cycling. It’s an ideal choice for pressure measurement for mid- to high-volume applications.

Protecting Pressure Transducers

Here are some tips I’ve found to be successful in protecting pressure transducers used in mobile hydraulics:

- Remove air from the hydraulic system to significantly reduce the magnitude of hydraulic pressure spikes.

- Avoid placing pressure transducers at the end of long and/or straight runs of pipe.

- Consider using the highest-pressure range transducer to meet application requirements.

- Install pressure snubbers or dampers between the process and the pressure instrument connection with different grades of porosity selection for protection.

- Install a throttle screw or plug in the process connection to dampen pressure spikes and pulsation.

- Install capillary lines to remote mount the pressure instrument away from shock and vibration. This prevents pressure spikes and pulsation by increasing the throttling effect due to the small size tubing.

- Dampeners are a cost efficient and effective choice to prevent damaging effects of pressure spikes and pulsation.

Pressure Switches in Mobile Hydraulics

A high-quality pressure switch for mobile hydraulics should not be sensitive to shock or vibration but should react to pressure pulses between 5 to 10 milliseconds. Premature switching can occur if pressure spikes or pulsation overcome the set point.

Throttling devices are also used to minimize pressure spikes and pulsation. Remote mount pressure switches in a shock and vibration-free location with capillary are the best practice to eliminate pressure spikes or pulsation, or a pressure snubber can be installed between the process and pressure switch to dampen pressure spikes and pulsation.

Pressure Gauges in Mobile Hydraulics

Digital pressure gauges are less vulnerable to shock and vibration than analog or mechanical pressure gauges. Still, protecting all pressure devices for better performance is a good practice. The impact of shock and vibration will damage mechanical pressure gauges in several ways:

- Pressure spikes and pulsation effects are clearly visual on mechanical pressure gauges as the pointer upsurges rapidly in response.

- If the pointer fluctuates, it’s difficult to accurately read the pressure gauge.

- Pressure gauge movement will wear the gear teeth across the segment when exposed to low frequency/high amplitude signal known as pressure spikes.

The best practice to prevent damage from shock and vibration is to remote mount pressure gauges with capillary. For analog gauges, use a fill liquid such as glycerin or silicon. Ashcroft offers liquid fill substitutions such as PLUS!™ Performance.

Throttle screws or throttle plugs installed in the pressure gauge process connection can restrict the flow and minimize pressure spikes and pulsation. You can also install pressure snubbers or dampers between the process and the pressure gauge.

Pressure Instrument Classifications

Mobile hydraulics applications require pressure instruments that offer the most rugged electrical, mechanical, and environmental protection due to the extreme outdoor dynamic and remote operating conditions.

There are two types of enclosure protection classifications: National Electronic Manufacturers Association (NEMA) ratings and Ingress Protection (IP) ratings.

Though NEMA and IP ratings are not identical, they are similar and can often be used interchangeably for rating enclosures of pressure instruments.

IP ratings specify standards for protection against the ingress of solid foreign objects or liquids, while NEMA ratings also define protection against other conditions, such as corrosive agents. Typically, most pressure instrument manufacturers define the instrument temperature specifications on the datasheet. Pressure transducers with NEMA 4 or IP66 ratings and above are acceptable to be used in most mobile hydraulics.

NEMA 4 Enclosures are adequate for outdoor use, protect against falling dirt, rain, sleet, snow, windblown dust, splashing water, or hose-directed water, and will be intact by the external formation of ice on the enclosure. IP66 offers protection against dust and low-pressure jets of water from all directions.

Mobile hydraulic systems require strength capacity, fast response, and precise control, which is possible with pressure instruments such as pressure transducers, pressure switches, and pressure gauges.

I hope you understand the importance of quality pressure instruments in your mobile hydraulics and how you can keep them safe in harsh conditions. The Ashcroft A series is a great place to start your research. You can also contact us today to talk to one of our industry experts and get all your questions answered.