Micron Eagle Hydraulics: Revolutionising Fluid Condition Monitoring with FROG

Solution Transforms Proactive Maintenance, Maximises Cost Efficiency and Enhances Environmental Sustainability

Photography courtesy of Micron Eagle Hydraulics.

Micron Eagle Hydraulics has launched a game-changing product that supports real-time monitoring of industrial fluid systems, saving both time and cost.

Fluid-fitness Remote Online Guardian (FROG) is an advanced digital transformation solution providing live remote monitoring that reshapes fluid management and industrial maintenance.

In this context, ‘fluid’ refers to essential industrial liquids such as hydraulic fluids, lubricants, and certain fuels, critical to the smooth and efficient running of machinery.

FROG offers predictive intelligence and customizable alerts to monitor these fluids in real time, enabling proactive asset management.

By detecting contamination issues, FROG helps prevent costly downtime, improve operational efficiency, and support sustainability, ultimately transforming maintenance practices and driving enhanced performance. FROG helps reduce the need for frequent handling and disposal of fluids, contributing to a lower environmental impact by minimizing waste and hazardous disposal requirements.

Photography courtesy of Micron Eagle Hydraulics.

FROG is the first product developed under Micron Eagle’s Fluid Fitness Technology (FFT) program. This initiative is designed to transform how industries monitor and manage fluids, improving operational efficiency, extending equipment lifespans, and refining maintenance practices. FFT also prioritizes fostering collaboration and open dialogue within the industry, ensuring that solutions are responsive to both current needs and emerging challenges. FFT aims to raise fluid performance standards through this innovative approach while addressing complex industry demands with cutting-edge technology and expertise.

Photography courtesy of Micron Eagle Hydraulics.

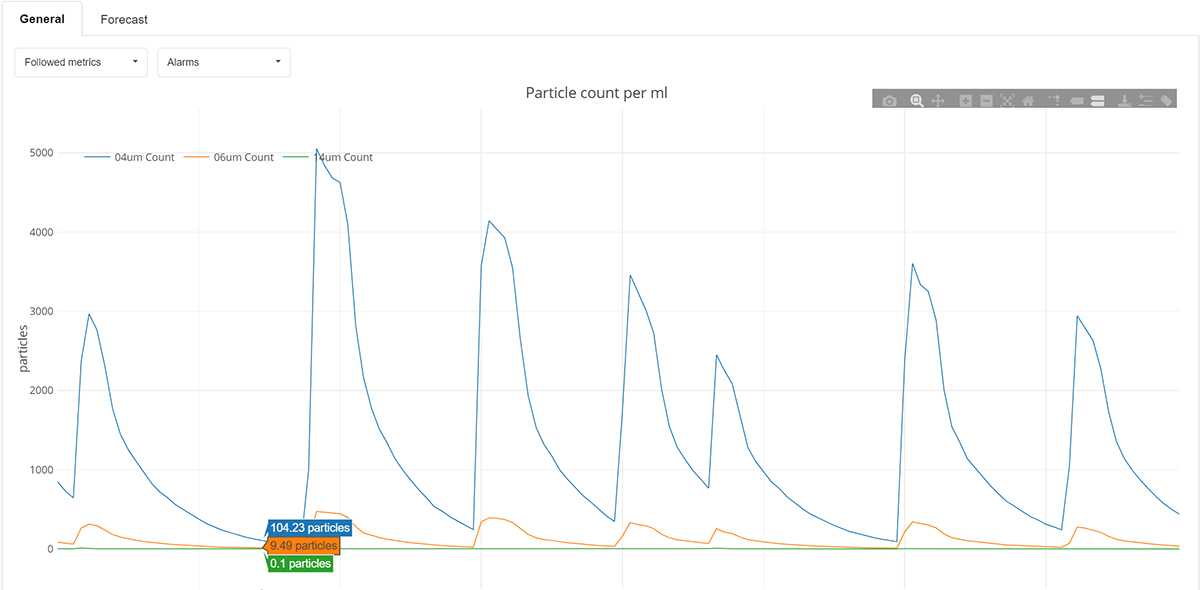

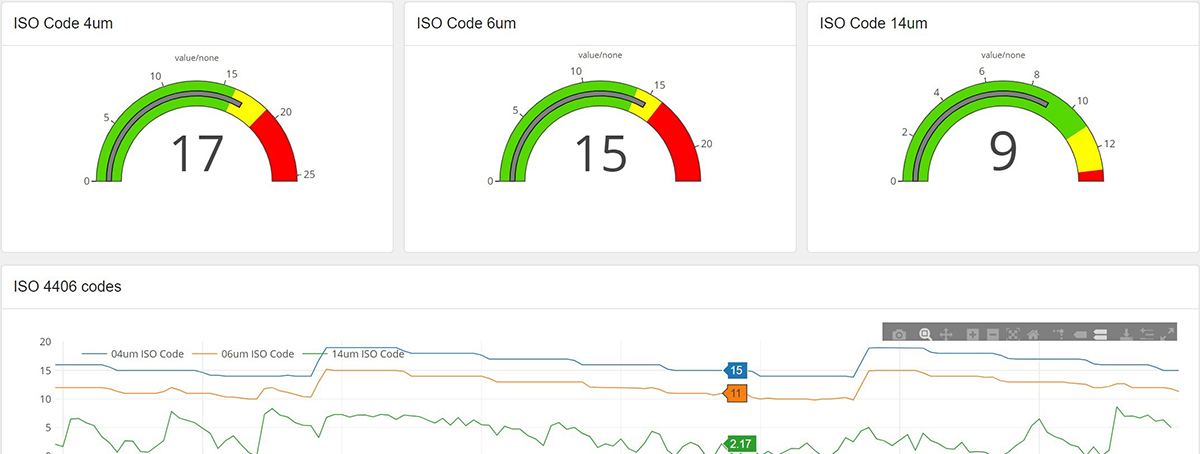

The solution offers a sleek and intuitive interface, allowing users to define precise set points for various elements such as contamination levels, temperature, relative humidity, and pressure.

Combined with the appropriate fluid conditioning unit, FROG forms a patented solution that has already secured contracts in the UK, the Middle East, and Africa. The development of this innovation was led by Henry Nagel, a director at Micron Eagle, based in Blackburn, Aberdeenshire [United Kingdom].

FROG’s cloud-based dashboard provides real-time data accessible to maintenance teams and management, whether offshore or onshore, via desktop or mobile device. It’s a preventative approach – one with visibility of system fluid health and notification of issues.

Advanced analytics tools allow the identification of trends to facilitate proactive maintenance without disrupting existing workflows.

Industries such as offshore oil and gas, manufacturing, transportation, and power generation require robust fluid monitoring to ensure optimal equipment performance and reliability. In offshore oil and gas, monitoring lubricating and functional system fluids is crucial for safety and operational efficiency. Manufacturing sectors benefit from fluid monitoring in production machinery, hydraulic presses, and assembly lines to minimize downtime and maintain precision. The transportation industry is increasingly reliant on effective fluid management to support sustainability goals. In power generation, maintaining the quality of turbine and generator fluids is of paramount importance in the prevention of outages.

A New Era in FluidMonitoring

Fluid monitoring relies on periodic manual sampling and lab analysis – a time-consuming process that does not capitalize on today’s digitization approach. This traditional periodic sampling method can also pose potential issues:

- Elongated process: Sending samples to labs can take weeks, potentially causing sample degradation and delaying crucial maintenance decisions.

- Snapshot Data: Lab tests provide only periodic snapshots, missing ongoing changes in fluid conditions.

- Potential for Errors: Manual sampling can introduce contaminants, leading to inaccurate results.

Aligned with today’s automated processes, FROG communicates ‘live’ insights into the condition of systems fluids, allowing for proactive maintenance and significant cost savings, reducing the potential for error.

Game-Changing Benefits

FROG is a game-changer for several reasons:

- Proactive Maintenance: By enabling early detection of fluid issues, FROG’s real time monitoring and communicating ability supports proactive decision-making and preventive maintenance.

- Cost-Efficiency: Live system communication allows the optimization of equipment performance, extends asset lifespan, and lowers maintenance costs.

- Environmental Impact: FROG’s data has the scope to reduce environmental impact by minimizing fluid waste through precise monitoring and proactive maintenance.

- Data-Driven Decisions: Utilise advanced analytics and trend detection to improve maintenance decision-making, enhance overall efficiency, and provide immediate notifications of condition changes.

- Technical Support: The innovation seamlessly integrates with existing systems, with support from the FROG team.

Transforming Market Sectors

FROG’s real-time dashboard is particularly beneficial across multiple market sectors:

- Offshore oil and gas: Scope to ensure the reliability of critical equipment in harsh environments, minimizing operational risks and enhancing safety.

- Manufacturing: Opportunities to enhance machinery performance and lifespan, leading to increased productivity and reduced operational costs.

- Transportation: Supports maintenance efforts, optimizing performance and reducing maintenance expenses.

- Power generation: Assists in the smooth operation of turbines and other critical machinery, helping in the prevention of costly outages and enhancing energy efficiency.

The High Cost of Poor Fluid Monitoring

Failing to properly monitor fluid systems can lead to significant financial consequences. The replacement and disposal of contaminated fluids not only carry high costs but also present environmental risks. Additionally, component failures caused by unfit or poorly maintained fluids can lead to costly downtime, resulting in lost production and further impacting profitability.

Engineering Precision

FROG offers precision, putting clients in control. Sensors track contamination, humidity, temperature – and other information – transmitting data to a secure portal. This continuous stream of real-time data allows for swift anomaly detection and trend analysis, empowering teams to anticipate issues and plan ahead.

FROG: The Vital Live Overview of Your Assets

FROG: The Vital Live Overview of Your Assets

FROG provides a comprehensive solution for fluid management, offering a range of benefits designed to enhance operational efficiency and asset longevity. These include:

- Predictive Intelligence: Advanced algorithms that detect subtle patterns, delivering valuable insights for proactive maintenance planning.

- Customizable Alerts: Users can set specific thresholds, with real-time alerts keeping them in control of their operations.

- Scalable Solutions: FROG’s adaptable design meets the needs of businesses of any size, from single-unit operations to enterprise-wide systems.

Supporting Opportunities for Micron Eagle Products

The data provided by FROG can also enhance the performance and maintenance strategies for other Micron Eagle products. By integrating FROG’s real-time monitoring data, companies can create a more comprehensive and efficient maintenance ecosystem, further driving operational excellence.