New Sealing Technology and Materials for More Efficient and Sustainable Heavy-Duty Equipment

By Andrew Iddeson, Global Technical Director, Hallite Seals

and Chuck White, Global Product Development Manager, Hallite Seals

There is an ever-growing demand, in the Fluid Power Industry, for sealing products manufactured through sustainable practices, that can withstand the harshest operating conditions. Equally, there is a crucial emphasis on enhancing energy efficiency to minimize the frictional “drag” exerted by the seal on the dynamic sealing surface. To achieve less friction, the design of the seal must introduce less resistance without compromising the amount of permissible boundary lubrication that is allowed to pass underneath the sealing lip. Navigating the ever-changing needs of the market prompts seal manufacturers to explore unconventional materials and designs. These solutions must address the challenges posed by harsher operating conditions, improve performance and efficiency, and incorporate sustainable materials.

Let’s look at how we define each of these characteristics before considering some sealing innovations manufactured to address them.

Harsher operating conditions

Heavy-duty equipment operators are familiar with harsh conditions, which often include extreme temperatures, pressures, speeds, and media. However, as the fluid power market evolves to more sustainable systems the demand for sealing components increases. System designs are moving away from a centralized hydraulic pump/reservoir to hydraulic/pump systems that drive portions of the unit, significantly reducing the amount of fluid present in the system and resulting in higher temperatures. Weight reduction is also a consideration, meaning that fluid power components, such as hydraulic cylinders, must become smaller yet maintain the capability to perform at the same level in the application, resulting in higher operating pressures. Finally, all of this must be accomplished with more sustainable fluids, which can adversely affect common sealing materials. Though challenging, there are new innovative products designed to meet the industry’s impending needs.

Better performance and efficiency

Energy conservation is increasingly crucial due to the hybridization and electrification of off-road equipment. While sealing systems contribute a small proportion to overall energy consumption, reducing friction without compromising seal effectiveness is vital. This requires not only innovative design considerations but also the use of advanced materials to achieve optimal results.

Sustainable materials

Sealing applications utilize a range of materials, including thermoplastic polyurethanes, polyesters, acetals, nylons, and PTFE. As sustainability gains prominence, questions arise about the environmental impact of these materials and fillers. Seal manufacturers are compelled to explore alternative materials, challenging the status quo and demanding creative solutions to meet market demands.

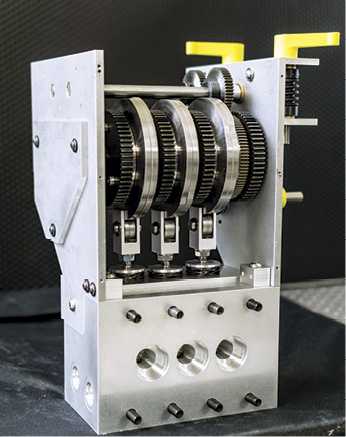

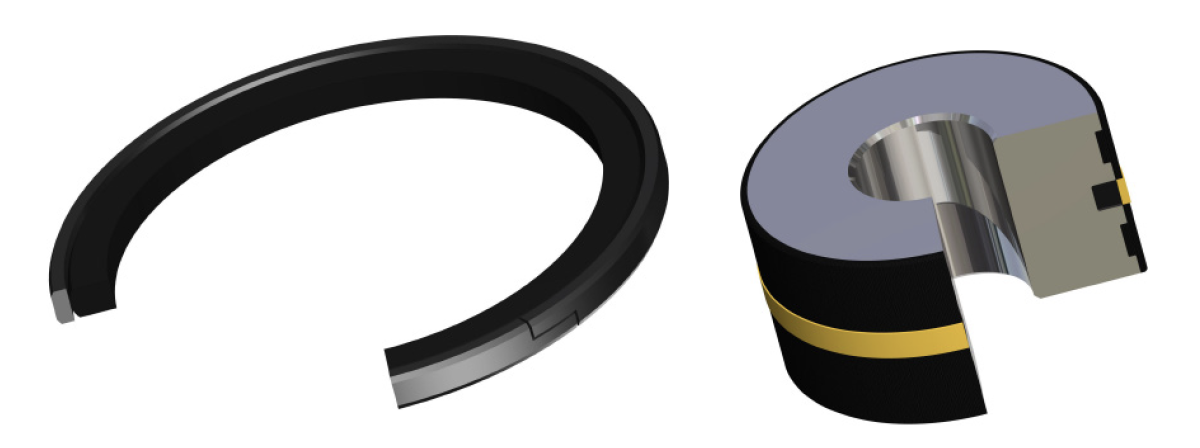

714 (left) and 720 Unitized pistons and glands (right)

Three seal innovations respond to market demand

1. 714 Two-piece Double Acting Piston Seal

The 714 is a heavy-duty piston seal designed to withstand pressures up to 52 MPa (7500 PSI) and continuous operation temperatures up to 100° C (212°F). Its glass-filled nylon face prevents extrusion at high temperatures/pressures, replaces a typical four-piece capped T seal, and can be recyclable, offering a sustainable solution.

2. Unitized Pistons and Glands

Extrusion of sealing material is a primary cause of seal failures. Unitized pistons and glands, featuring over-molded components are precision machined to minimize extrusion gaps and offer enhanced seal life, higher operating temperatures, and pressures. Unitized pistons and glands are over-molded with a bearing material, reducing the overall length required, resulting in less material and weight without the risk of metal-to-metal contact.

In grapple and shearer applications, heavy side load, heat generation, and pressure spikes are the norm. The unitized product allows an engineer to address these concerns by taking advantage of the significant side load protection (when compared to the non-unitized alternative) without having to redesign the original piston and gland envelope to allow for more bearing area. The designer can maintain the existing design envelope while upgrading the cylinder performance. Thus, the upgrade is retroactive for a product that exists in the field already and is a big improvement for new cylinders. In addition, the tight extrusion gaps provided by the unitized piston and gland help increase seal life by reducing the number of contaminants that reach the seals and prevent extrusion of the seal during high cyclic usage.

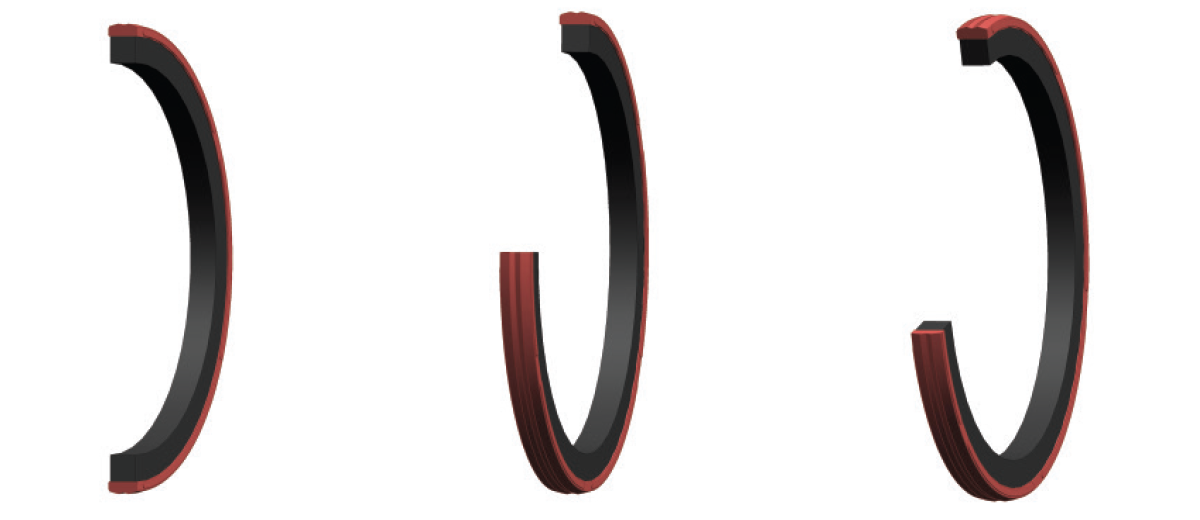

777 half and quarter views

3. 777 Two-piece Compact Piston Seal

Manufactured from state-of-the-art thermoplastic polyurethane (TPU), the 777 seal offers enhanced wear resistance in a wide range of operating temperatures. In addition, optimized tooling ensures the parts are provided with both high-quality and cost-effective methods that contribute to the product’s performance and longevity, and this contributes to reducing waste.

Testing drives technology and material advancements forward

Comprehensive testing is critical for developing materials that align with sustainability objectives and validate seal performance. Hallite’s test capabilities focus on assessing product performance, providing data confirming the benefits of design innovations.

Conclusion

Efficient, sustainable products necessitate a focus on materials and products that reduce energy consumption and enhance longevity. Collaborating with manufacturers committed to continuous improvement in sealing technology benefits equipment manufacturers and operators alike.