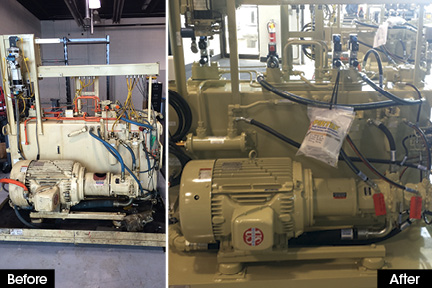

PIRTEK Sterling Heights Rebuilds Power Units

A driveline-manufacturing engineer contacted John Martin, director of sales and marketing for PIRTEK Detroit, to request a quote to rebuild four old hydraulic power units. The client designs, manufactures, and distributes driveline systems and service parts for vehicles, and the hydraulic power units are a critical piece of equipment in the production process. They supply hydraulic power to the friction welders that build the drive shafts. The units were running extremely hot, causing the company to make frequent, sometimes daily, repairs.

Each component of the units, such as valves, switches, gauges, electric motor, motor mounts, pumps, chiller, hydraulic tubes, and hoses were removed and replaced with new/remanufactured components. The motors were cleaned, inspected, and rewound. The pumps and motors were calibrated to factory specs and included certification paperwork for verification. The chiller was also upgraded to resolve the overheating issue.