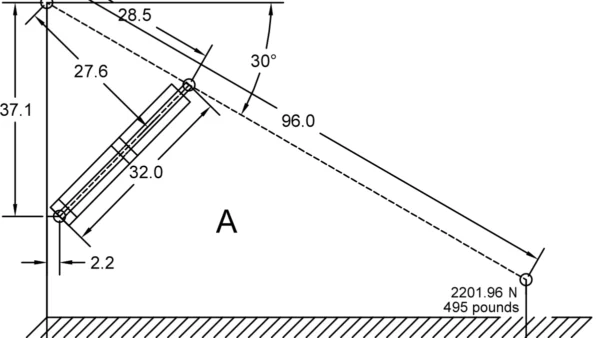

Problem: Sheet Metal Shear

This month’s problem is to convert a manually operated sheet metal shear to operate on pneumatics. Looking at the diagram, you will see the placement of the two pneumatic cylinders mounted at a 75-degree angle, each with a two-inch bore operating at 100 psi. The cylinders are 20″ from the pivot, and the manual bar that one would stand on is 24″ from the pivot. How much would a person have to weigh, standing on the bar, to develop the same force as is produced by the two cylinders? Assume 100% efficiency.

Find Out The Solution

Moment equations are used to find the moment of a force or what one could call “torque.” This is a force multiplied by a perpendicular distance. Here we have a pair of cylinders pushing down at 75 degrees. I think the easiest way to calculate this using “shop math” is to take the force of the two cylinders and multiply by the sine of 75 degrees.

A = D x D x 0.7854 and F = PA. Therefore, 2 x 2 x 0.7854 = 3.14 sq. in.

Using F = PA, 3.14 x 100 = 314 lbs of force for each cylinder. Two cylinders = 628 lbs.

Now we need to know what the equivalent force would be if the cylinder were pushed perpendicular to the bar. If you calculated the sine of 75 degrees, you get 0.9659, which means you will have 96.59% of the 628 lbs pushing straight down.

628 x sine of 75 = 606.6 lbs.

Writing the moment equations, you can say that 606.6 lbs. x 20 inches of leverage is equal to the weight of a person x 24 inches. (606.6 x 20 / 24 = 505.5 pounds.) Without rounding off any of the answers until the end, you should get 505.76 pounds. If the shear is designed for a 250-lb person, one could reduce the air pressure to get the same results.

Deadline past. Not available for submissions.

Winning Answer Submitted By:

Matthew Smith, CFPPS, VOX Printing, Oklahoma City, OK

Correct Submissions By:

Harold Lawson, CFPPS, Air, Inc., Franklin, MA

Stuart Johanson, Hennepin Technical College, Brooklyn Park, MN

Edward Day, CFPPS, Norgren, Inc., Littleton, CO

Richard Throop, CFPAI, CFPAJPP, CFPS, CFPMM, CFPMT, Neff Engineering,

Flint, MI

Ronald Arreola, CFPS, Hydraforce, Inc., Lincolnshire, IL

David Chatterton, CFPS, CFPECS, SMC Corporation, Chicago, IL

John Woolridge, Sunsource, Shakopee, IL

George Fling, CFPS, Dallas, TX

Bernie Mendoza, CFPS, Sauer-Danfoss, Ames, IA

Leon Cuhel, CFPS, North American Hydraulics, Inc., Baton Rouge, LA

By Ernie Parker, AI, AJPP, AJPPCC, S, MT, MM, MIH, MIP, MMH,

Fluid Power Instructor, Hennepin Technical College, EParker@Hennepintech.edu

This teaser is printed in the Fluid Power Journal. Submit your answer HERE. Those who submit the correct answer before the deadline will have their names printed in the Society Page newsletter and in Fluid Power Journal. The winners will also be entered into a drawing for a special gift.