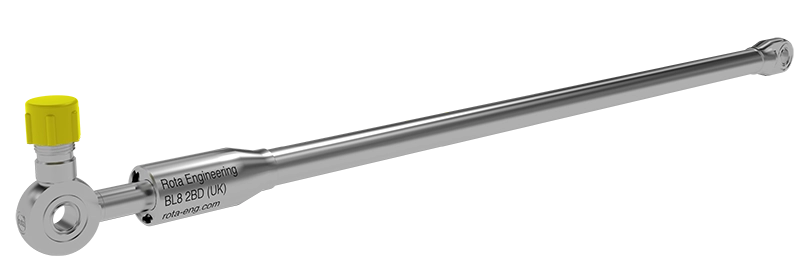

Rota Offers Transducer for Robust Environments

Rota Engineering recently released its LL transducer series, which it designed for monitoring ultra-robust environments.

Sharing the same technology as Rota’s internal LA series, the LL series can be mounted directly to the machine or mirror the pin-to-pin dimension of the cylinder, which requires monitoring. This flexibility means finding suitable mounting points is easier, and integration costs are lower, as there are no cylinder machining costs. Rota can tailor the open and closed transducer body centers to match existing machine or cylinder geometry. It’s this ease of installation which makes the LL series ideal for rapid prototyping, small batches and production volumes.

By virtue of its design, the LL series is field-replaceable, which reduces machine downtime, associated repair costs, and loss of productivity. The independent-mount design allows OEM installers or dealers to offer customized solutions. The LL series may be added during production of the machine or at the dealer location, depending on the specification of machine and level of control or automation required by the customer.

Other features of Rota’s LL series include a high vibration rating, IP69K OPEN FACE M12 and Deutsch connectors, absolute signal, -30° to 80°C (-22°F to 176°F) operating temperature range, and optional velocity option available in CANbus signal.

For more information, email info@rota-eng.com or visit www.rota-eng.com/innovation.