Select Components for Pneumatic Systems

Size Air Receivers

Air receivers serve many functions: as a pulsation dampener, as an air reservoir, and as an air conditioner. They also serve an important function, if properly designed, in that they reduce wear and tear on a compressor, the capacity control system, and the motor driving the compressor by preventing excessive compressor cycling.

As a pulsation dampener, the receiver allows the compressor to supply air at a constant and steady pressure at the outlet of the receiver, even though the inlet pressure to the receiver varies during each compression cycle.

As an air reservoir, the receiver will supply more air for short periods of time during peak periods of use than the compressor can deliver. Thus, an air system demanding 25 scfm for several minutes may be supplied by a compressor delivering only 20 scfm, during the same period of time. Of course, there must also be time during the use cycle when air system demand is sufficiently less than 20 scfm, so that the compressor may build back an oversupply of air in the receiver for the next time that demand exceeds supply.

The receiver also conditions air by cooling it and removing condensed water through a drain in the bottom.

Cool air improves system efficiency. By removing water, components located downstream will be less likely to deteriorate due to the formation of rust and corrosion.

There are several methods used to size an air receiver, from specifically calculated volume, to rules of thumb. A commonly accepted industry practice is to size the air receiver volume to equal 1 gallon of volume per every output cfm of air from the compressor. For example, 30 cfm at the compressor output would require a 30 gallon receiver.

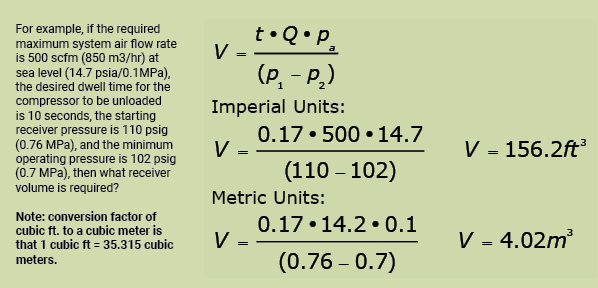

Calculating the required air receiver size, and to optimize the sizing, requires determining the desired dwell time or unloading time of the compressor, as well as determining the maximum required air flow.

The minimum satisfactory operating pressure must be known as well.

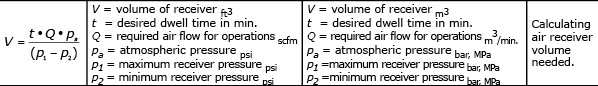

The equation to determine is

Sometimes it is advantageous to install a secondary air receiver within the system. The advantage of installing a secondary tank at a location where a higher flow rate may be required on an intermittent basis is that if an intermittent process can be averaged out (which an air tank will do), the instantaneous requirement of the compressed air system is reduced. This will help to minimize excessive compressor cycling.

Test Your Skills

An important function of an air receiver is to:

a. Add humidity to the air.

b. Increase cycle time of an actuator.

c. Increase the inlet flow to the compressor.

d. Help condition the air.

e. Ensure that the compressor runs continuously and therefore removes need for capacity control.