Signs of the Times: Expanding Hydraulic Hose Performance Metrics

By Cindy Cookson, VP Hydraulics Global Product Line Management, Gates

By Cindy Cookson, VP Hydraulics Global Product Line Management, Gates

At one time, it may have been common to ask about a hose’s rating. The answer might be something like, “It’s a half-inch one-wire hose.” Or “It’s a three-quarter-inch R2 hose.” A more sophisticated answer might have been more detailed: “It’s a half-MBR dash 8, 3,000 psi hose rated to 600,000 impulse cycles.”

Hydraulic hose performance has historically been characterized by working pressure, temperature, and bend radius, or by construction (i.e., one-wire braid), in the absence of a clear understanding of the other criteria. While those criteria are still important, hydraulic applications are evolving to demand more of the hydraulic system, and hose and coupling technologies are advancing to deliver more sophisticated products. These advancements require us to expand our evaluation criteria beyond historic characterizations. Contemporary machine designs are pushing the limits of legacy hydraulic hoses, increasing the importance of performance criteria such as flexibility, weight, abrasion resistance, and ozone resistance.

Many industry standards dictate how a hose should perform. For example, four major industry standards – SAE, EN, JIS, and ISO – all define the hose pressure, minimum bend radius, temperature, and impulse cycle requirements for each hose size and for various pressure classes. Some even define aspects of the construction and dimensions, which are largely related to the hose-coupling interface and coupling compatibility. These industry standards define how a hose is expected to perform and the test methods that verify performance, enabling end users to compare hoses and select the best one for their application. Fortunately, these industry standards also define test methods for other performance characteristics, including flexibility, abrasion resistance, and ozone resistance.

Flexibility

As heavy-duty equipment ramps up in pressures and hydraulic systems become more compact, the flexibility of hydraulic hose is increasingly important. Conventionally, higher-pressure hoses require more wire reinforcement to achieve those pressures. But as more wire is added the hose becomes increasingly stiff, to the point where it feels more like a pipe than a hose. Adding to this challenge, a compact hydraulic system has less space to route hoses, resulting in more complex hose routings with tighter bend requirements. This is where hose flexibility is a true performance differentiator between hydraulic hose options. A flexible hose can solve some of the following problems in a hydraulic system.

- Leak-free connection at the port or manifold. Stiff hoses are difficult to align at the port and can suffer from leakage related to crossed threads or other misalignment at the port. A flexible hose promotes a

leak-free connection. - Achieve complex routings. Stiff hoses can be difficult or impossible to route in an intricate application. A flexible hose may simply make a hose routing achievable.

- Easier and faster installation. Stiff hoses take more time to route. In head-to-head studies of Gates MXT hose versus Gates R2 hose, MXT required 50% or less time to route, which can translate to direct labor savings in both original equipment and replacement installations.

- Ergonomics and safety improvements. Stiff hoses increase the stress and strain on the operator during installation. A more flexible hose reduces fatigue and strain during installation, leading to healthier and safer worksites. Additionally, spring-back from a stiff hose can cause injuries to an unsuspecting operator.

- Improved packaging. A rigid hose is difficult to handle and oftentimes must be banded to a pallet or contained within a carton. Conversely, flexible hose can be coiled on a reel for easy handling and storage.

- Equipment responsiveness. Stiff hoses in dynamic applications require some system power just to flex the hose. More flexible hoses deliver more responsive equipment.

- Minimize reactive maintenance. Stiff hoses are difficult to contain in hose tracks, where they are known to break the track. Stiff hoses also tend to rub against machine components or other hoses in dynamic applications. A flexible hose reduces wear and tear on the machine.

Flexibility is often confused with minimum bend radius (MBR), but they are two different performance metrics. MBR is a hose rating that is established during impulse testing; it’s the radius at which the hose bends during the impulse test. MBR is typically measured in inches or millimeters, and it defines the tightest bend allowed in a hose routing. The lower the MBR, the tighter the hose can bend, and the shorter the hose assembly can achieve that routing. Conversely, flexibility is the force required to bend a hose. A tighter MBR shortens the length of the hose, whereas flexibility is the force required to bend a hose, which is related to the installation and dynamic use of the hose.

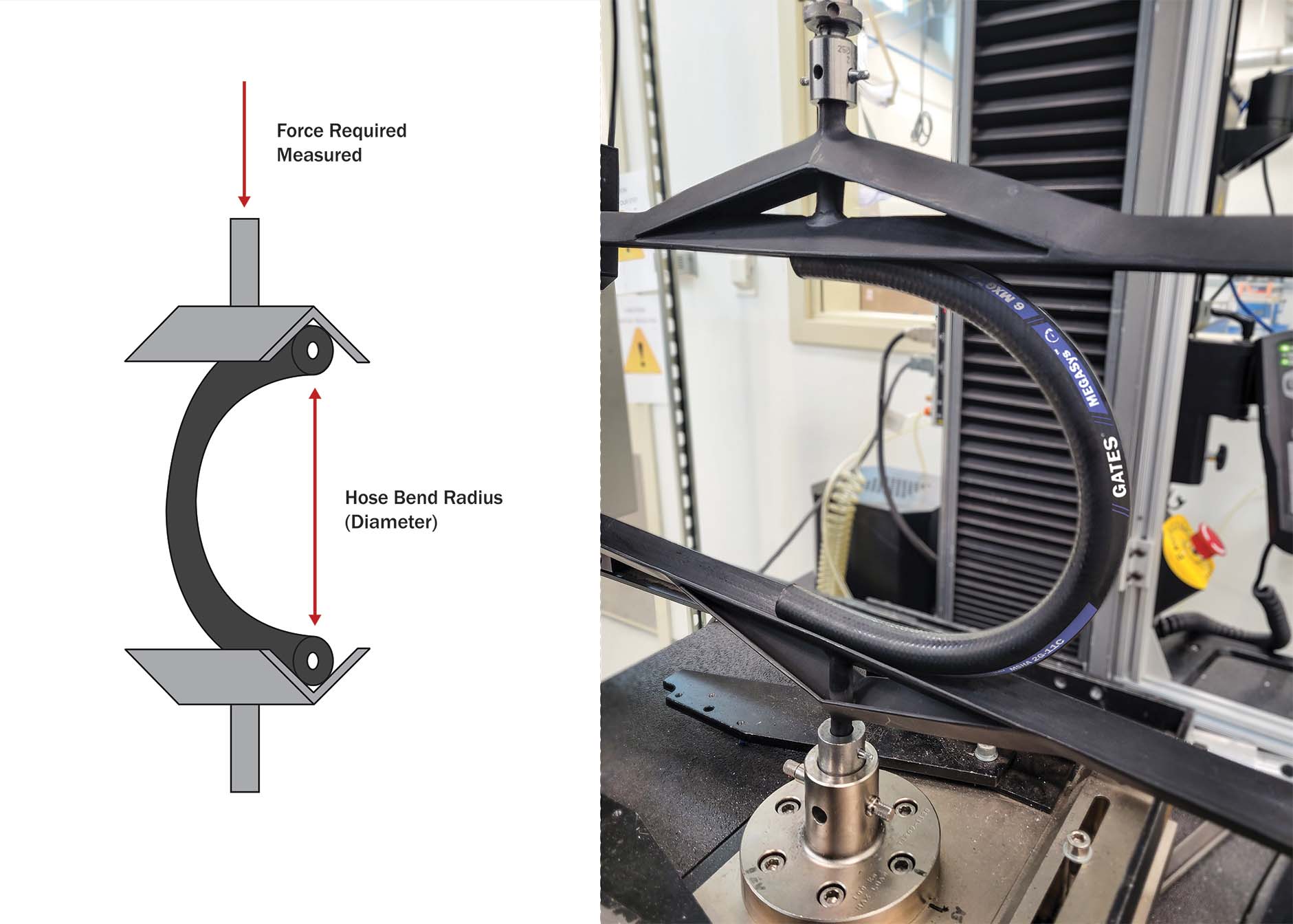

Returning to our discussion of standards, ISO 10619 defines four different methods for measuring the flexibility of an unpressurized hose at ambient temperature, which is a good measurement of the force required to install a hose in application. Gates uses method A2 to compare Gates and competitive hoses. An Instron test rig is employed to measure the force required as guides move vertically together to the hose MBR (see figure 1). This force is usually measured in pounds or kilograms, and a lower force-to-bend value means the hose is more flexible. By using an Instron, Gates continuously collects force measurements through an entire hose-bending range rather than at one specific bend radius. By gathering force measurements over the full hose-bending range, hoses with different MBRs can be compared at the same bend values. For example, an SAE 100R16 hose can be compared with an SAE 100R2 hose at a larger MBR without having to retest the samples.

Figure 1: Instron force-to-bend test rig.

To add further color to why flexibility matters, consider Gates MXG 5K hose, which is 25% more flexible than traditional 350-bar hoses. During field trials, an excavator operator noted the flexibility of MXG 5K hose. While traditional hoses required two people to route, MXG 5K could easily be routed with just one person, which drives true value in a labor-constrained situation. Another field trial in a tunnel-boring machine showed that MXG 5K routed in a space with just 100 mm (4 inches) clearance (see figure 2), whereas the legacy hose would not fit in that space. They were also able to route all hoses with just one person instead of two, and in many cases the operator could hand-tighten the termination with just one hand. Finally, the flexibility of the MXG 5K umbilical line formed a nice coil and handled easily, whereas the legacy hoses were cumbersome due to their stiffness (see figure 3).

Weight savings

When considering the weight savings of a hydraulic hose, users often wonder how the weight of the hose could possibly matter in a piece of equipment that weighs 10 or 20 tons. Overwhelmingly, original equipment engineers agree that in high-performance systems, both the overall weight as well as where the weight is located matters for a variety of reasons.

Figure 2: MXG 5K routed with only 100 mm

(4 inches) clearance. (Photo courtesy of Tenbusch.)

- Improved energy efficiency. Heavier hoses require more energy to move. Lightweight hoses can help fleets meet fuel-efficiency targets. This is especially important in electrification and hybrid platforms where weight-reduction efforts are necessary. More energy-efficient equipment can also stay in the field longer for improved uptime.

- Maintaining gross vehicle weight. Heavy-duty equipment is designed to stay below gross vehicle weight thresholds for shipping purposes. Lighter-weight equipment can be moved between sites using common transport vehicles.

- Reduced freight and shipping costs. Heavier hoses incur higher freight costs. Distributors that ship bulk hose directly benefit from lighter-weight hoses in their

logistics savings. - Improved equipment designs. Reducing weight in a boom arm means more machine power does actual work instead of lifting and moving hoses. A lighter-weight boom arm can also lead to reductions in counterweights for additional weight savings.

- Ergonomics and safety improvements. Lighter-weight hoses are more ergonomic to install and less fatiguing during bulk hose handling, with obvious ergonomic and safety advantages.

Again, let’s consider MXG 5K hose, which is more than 20% lighter than traditional

350-bar hoses. An excavator field trial revealed benefits related to weight savings. The lighter-weight hose was feasibly handled by one person, leading to direct labor savings during installation. A second benefit of the weight savings was seen in the dynamic application. When the boom is fully retracted, the weight of the traditional hose caused severe hose bending near the coupling. When using the lighter-weight MXG 5K hose, the bending issue was immediately relieved, resulting in extended hose durability (see figure 4.)

Figure 3: Umbilical line. (Photo courtesy of Tenbusch.)

Figure 4: MXG 5K installed on an excavator boom.

Abrasion resistance

As a material, rubber has many properties that make it ideal for hydraulic hoses. It is strong but flexible, it can withstand extreme temperatures, and it resists degradation from oils and other materials present in heavy-duty systems. For these reasons, rubber is an excellent choice to cover the hose when the cover’s primary purpose is to protect the hose reinforcement from damage. While standard rubber covers do a good job of protecting the hose from normal environmental conditions, some applications experience severe abrasion caused by poor hose routings, severe applications, congested hydraulic systems, or interactions with other machine components in dynamic installations. Unfortunately, external abrasion has been identified as one of the most common causes of premature hose failure. Most hose manufacturers make varying grades of hose covers to address these challenging applications.

Abrasion resistance is a measure of the rubber cover’s ability to resist damage from abrasion. The most common method for measuring abrasion resistance is described in the ISO 6945 test method, and it is still the most common way hose and original equipment manufacturers quantify abrasion resistance. However, the method has been withdrawn by the governing body due to the difficulty of duplicating exact test conditions and obtaining correlating results between locations. But it remains a useful test for side-by-side comparisons in the same location when all other variables can be controlled.

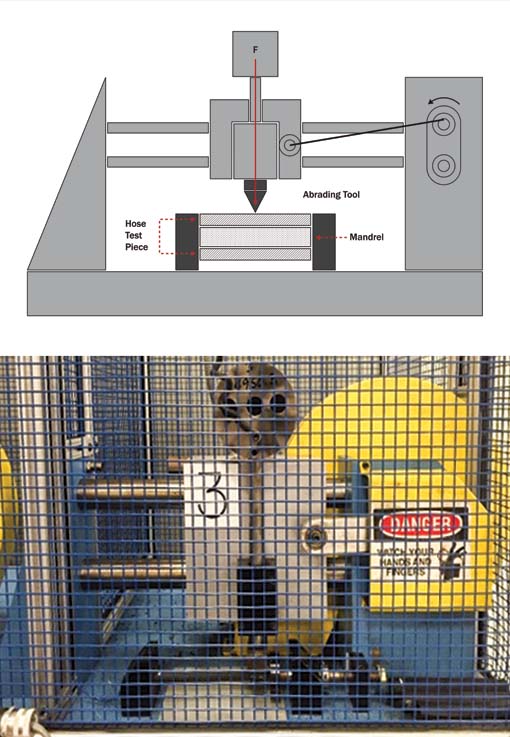

The test is conducted by cycling the abrading tool back and forth across the hose sample, measuring in grams the mass of weight loss that has occurred through the test. This test is not intended for predicting product abrasion life, nor for specifying a cycle count; rather it’s for the comparison of different cover materials. The apparatus used in the test is shown in figure 5. The test can be run using 25N or 50N force. The abrading tool is rubbed back and forth at 75 cycles per minute. The results are reported in one of three ways:

- How many grams were removed per 2,000 cycles (wear test).

- How many cycles it took to wear through the cover and reach the reinforcement (life test).

- How many grams were removed when the reinforcement is exposed (life test).

Gates mid-tier abrasion-resistant cover is called XtraTuff Plus. XTP has 25 times the abrasion resistance of a standard cover, which extends hose life in rugged applications. The XTP cover is standard on Gates MXG 4K and 5K hoses to ensure the cover performance matches the 1 million impulse cycle rating.

During MXG 4K field trials on a mining replacement application, the customer reported that the average life of their legacy spiral hose was just 35-40 days due to abrasion on the cover. Gates MXG 4K hose with XTP cover lasted more than 120 days before replacement, helping the operator realize reduced hose costs as well as improved uptime.

Figure 5: Abrasion test rig.

Ozone resistance

Ozone is created when ultraviolet (UV) light transforms oxygen into ozone. UV is generated by the sun as well as equipment with high-energy electrical discharge, like welding equipment. Therefore, equipment that operates outdoors or near electrical discharge sources is subject to damage from ozone exposure. Related to hydraulics hoses, ozone can react with rubber materials and cause cracks on the surface cover of the hose (see figure 6). Remember that the purpose of the cover is to protect the reinforcement from environmental damage. These cracks can allow moisture and debris to degrade the reinforcement and cause premature failure. Gates recommends replacing any hose where the cover is damaged and the reinforcement is exposed. Ozone cracking is commonly called dry rotting or weathering. Ozone cracks usually appear first on the most exposed and stretched rubber surfaces – usually the outside radius of a bent hose. Hoses that are frequently flexed in application are also more susceptible to ozone cracking.

A common industry standard test for measuring ozone resistance is ISO 7326:2016. It outlines five methods to test hose materials for ozone resistance:

- Whole hose test (bore sizes up to and including 25 mm).

- Hose section test (bore sizes greater than 25 mm).

- Hose cover test (bore sizes greater than 25 mm).

- Whole hose test (all bore sizes).

- Expandable hoses (i.e., textile reinforced hoses, all bore sizes).

Gates typically uses the first test method to compare hoses and covers for their ozone resistance. The hoses are fixed at their minimum bend radius and then suspended in an ozone chamber that is emitting a specified ozone concentration. The samples are examined for cracks at specified time intervals (e.g., 24 or 48 hours). The result is reported as the number of hours of ozone exposure before any cracks form.

The previously mentioned XTP cover is called “plus” because it resists both abrasion and ozone damage. The MXT hose is available with an optional XTP cover, and a field trial on an oil rig demonstrated the value of ozone resistance in this outdoor application. The top drive system was having issues with ozone damage on a legacy hose. Installing MXT-XTP eliminated premature failure related to

ozone issues.

Figure 6: Ozone cracks on the hose surface.

Performance redefined

Hose performance is no longer just about pressure, bend radius, and temperature. Evolving expectations are enabling higher-performing machines through enhancements in flexibility, weight savings, and resistance to environmental factors like abrasion and ozone. The additional performance metrics discussed in this article are not easily deciphered by looking at a hose layline or referencing traditional metrics in a catalog. Handling a hose side by side is telling, but the ultimate measure of these new performance metrics is in field trials. Improved performance and extended life are possible through these technology breakthroughs, which enable customers to push their hydraulics systems beyond traditional capabilities.

Maybe the next time you’re in a hydraulic distributor shop you’ll hear a discussion about hydraulic hose performance that includes some of these alternative performance metrics – flexibility, weight savings, abrasion resistance, and ozone resistance. Don’t be limited by what hoses did in the past. Hydraulic hose technology breakthroughs are redefining performance to solve hydraulic system challenges.