Smart & Sustainable Monitoring Solutions for Pneumatically-Driven Machines

By Jon Jensen, Industry Projects Manager, Energy,

and Nathan Eisel, National Product Development Manager,

and Sahith Raaghav Sanike, Energy Engineer,

SMC Corporation of America, CA.

Optimize productivity, CO2 reduction, and energy savings through enhanced monitoring. Learn how the design and implementation of smart devices at the machine level can help to achieve production goals, reduce downtime, and cut costs by making data-driven decisions. This paper will explore the ramifications of adding significant monitoring and communication to the standard modular air preparation system in the industrial automation workspace. Such a system can reduce compressed air use while digitally finger-printing the machine’s current performance. Let us use a case packer as an example: Typically, these machines have pneumatic actuators that operate at a remarkably high cycle rate. If the case packer is outfitted with sufficient monitoring, communication, and control, the end user can very quickly realize deep energy savings (25-40%) by “semi-automatically” switching the machine into one of two possible “eco modes” when the machine is idle. The end user can also take full advantage of the monitoring (via an OPC UA interface) to collect and analyze machine performance and establish condition-based maintenance (CBM) algorithms, thus minimizing breakdowns due to pneumatic component failure.The data stream could bypass the traditional methods of PLC mining and go directly to the end user’s Supervisory Control and Data Acquisition (SCADA) system to minimize integration effort, particularly on legacy machines.

Pneumatics is the discipline that describes compressed air flow and how to use the properties of compressed air to transmit energy or convert the same into force and motion. Pneumatic applications use the most widely available resource — air. Pneumatic systems are integral to industrial automation and are especially useful when machines need linear motion or elastic behavior. They also offer a functional way to store energy for subsequent uses. Pneumatic systems are clean, dependable, and simple to operate, and thus are widely used in the food & packaging, beverage & brewing, automotive, and pharmaceutical industries, to name a few. Pneumatic systems have good power density, low initial cost, and significant reliability. The only significant drawback is their low energy efficiency.Because of this inherent inefficiency, compressed air is typically one of the most expensive forms of power transmission used in industry, so much so that it is often considered a “third utility.” When viewed as an expensive utility, or process variable, proper management is required to minimize the environmental impact. The duty cycle of any pneumatic machine includes the supply of the compressed air, the mechanical work done by actuators/drives, and air expansion that generates noise. Air expansion – treated as energy loss – has the following sources: leakage through holes and breaks in pneumatic lines, leakage through damaged or mismatched connectors, and internal leakage in directional control valves, linear and rotary actuators, etc. Measuring leaks and other forms of compressed air waste from pneumatically-driven machines is difficult due to the geometry of the leaking components, safety barriers around the machinery, and scheduling enough planned downtime on the machine to perform a leak survey, since planned production always takes precedence. Therefore, calculating the system efficiency is quite challenging, necessitating the use of measuring equipment, trained and skilled professionals, and calculations. The main objective of this paper is to propose a user-friendly method for determining, optimizing, and eventually eliminating compressed air waste, using an affordable and simple monitoring system, hereafter referred to as an Air Management System, or AMS. It is a widely accepted truth in the pneumatic industry that most pneumatic component failures can be predicted by a leak. A byproduct of monitoring the key performance indicators (KPI’s) of pneumatic system performance, namely pressure and flow, will result in improved reliability. Having the data available will assist a production facility in implementing a condition-based maintenance program. Condition-based maintenance (CBM) is a widely followed industrial management philosophy that aims to minimize the total cost of inspection, repairs, and replacements. This is achieved only by continuous monitoring of the operational condition of a critical component or asset.

Continuously monitoring and optimizing compressed air to pneumatic-driven machinery is now possible using the approach proposed in this paper. As a result, energy losses are more easily identified and mitigated, the opportunity to produce cleaner and more sustainable products is provided, machine digitalization is achieved, costly downtime is avoided, and excessive maintenance-related expenditures are reduced. In 2022, SMC Corporation performed a six-month study at a key client’s facility, installing an Air Management System (AMS) on a bottle-filling production line with 10 machines. Results were extrapolated to 8760 hours of operation (24 X 365). The main objectives were to: Demonstrate the use of an AMS to conserve energy on production machines during their idle time.

Demonstrate secure wireless Data Acquisition from IO-Link sensors on the machine using OPC UA protocol without the use of an edge device.

Make the data available for future integration into the client’s existing SCADA system for purposes of condition-based maintenance and digitalization.

Air Management System (AMS)

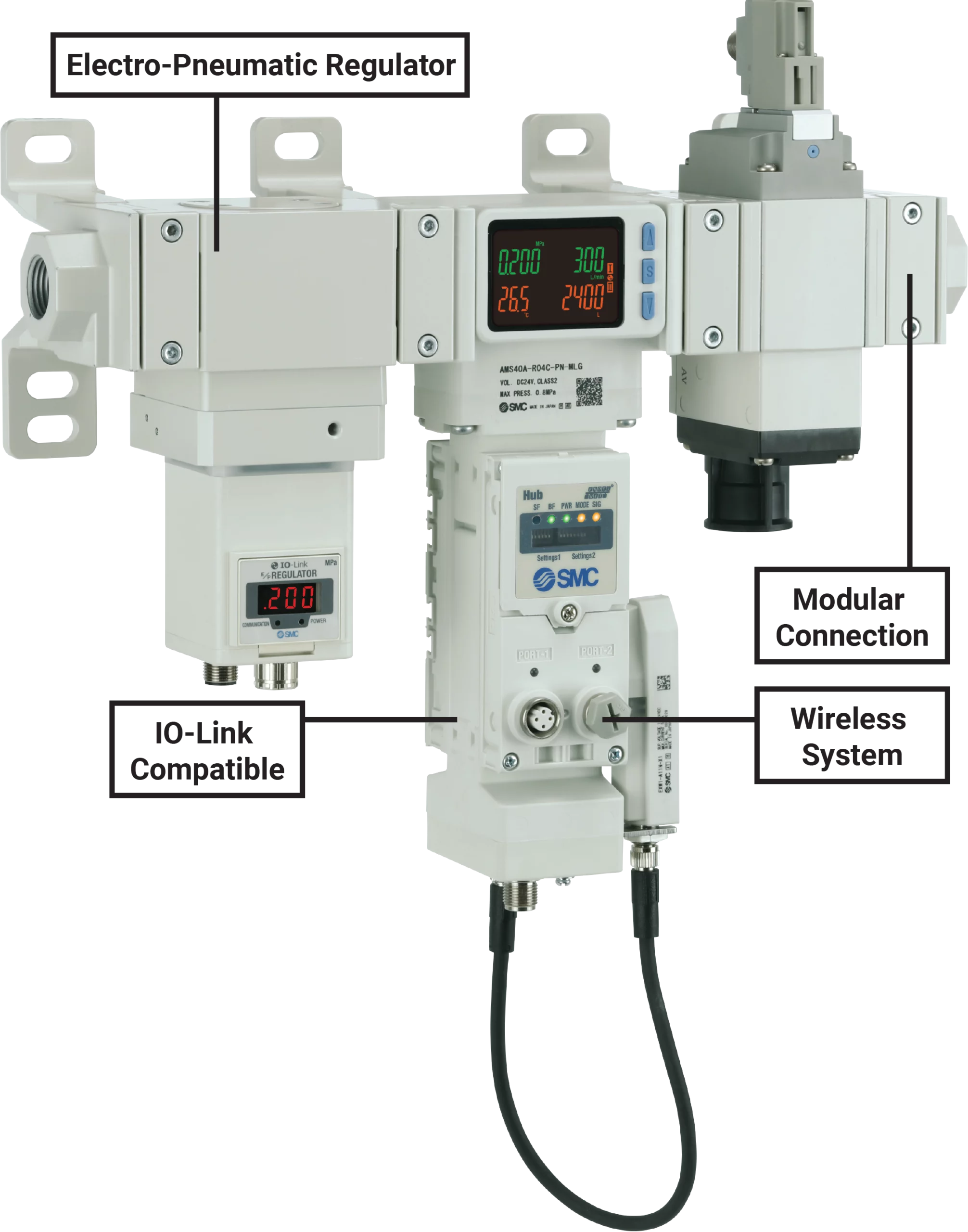

The Air Management System evaluated was an assembly of components, consisting of the following:

- Electro-pneumatic pressure regulators

- Manual pressure regulators

- Multiple communications units (HUB):

- 2AMS base units

- 8 remote units

- Residual pressure relief valves

The AMS system was designed to easily and semi- automatically reduce or remove (isolate) the air pressure supplied to a machine while idle. The primary sustainability benefit comes from using the compressed air when it is needed to run the production process and reducing or removing the pressure when the machine has paused, no matter how briefly. Consequently, leakage and other non-productive uses of compressed air on the machine are reduced or removed. Consider, as an analogy, that most modern automobiles set the engine to idle when the vehicle is coasting and turn off the engine completely when the vehicle is stopped, thus reducing, or removing the need for fuel.

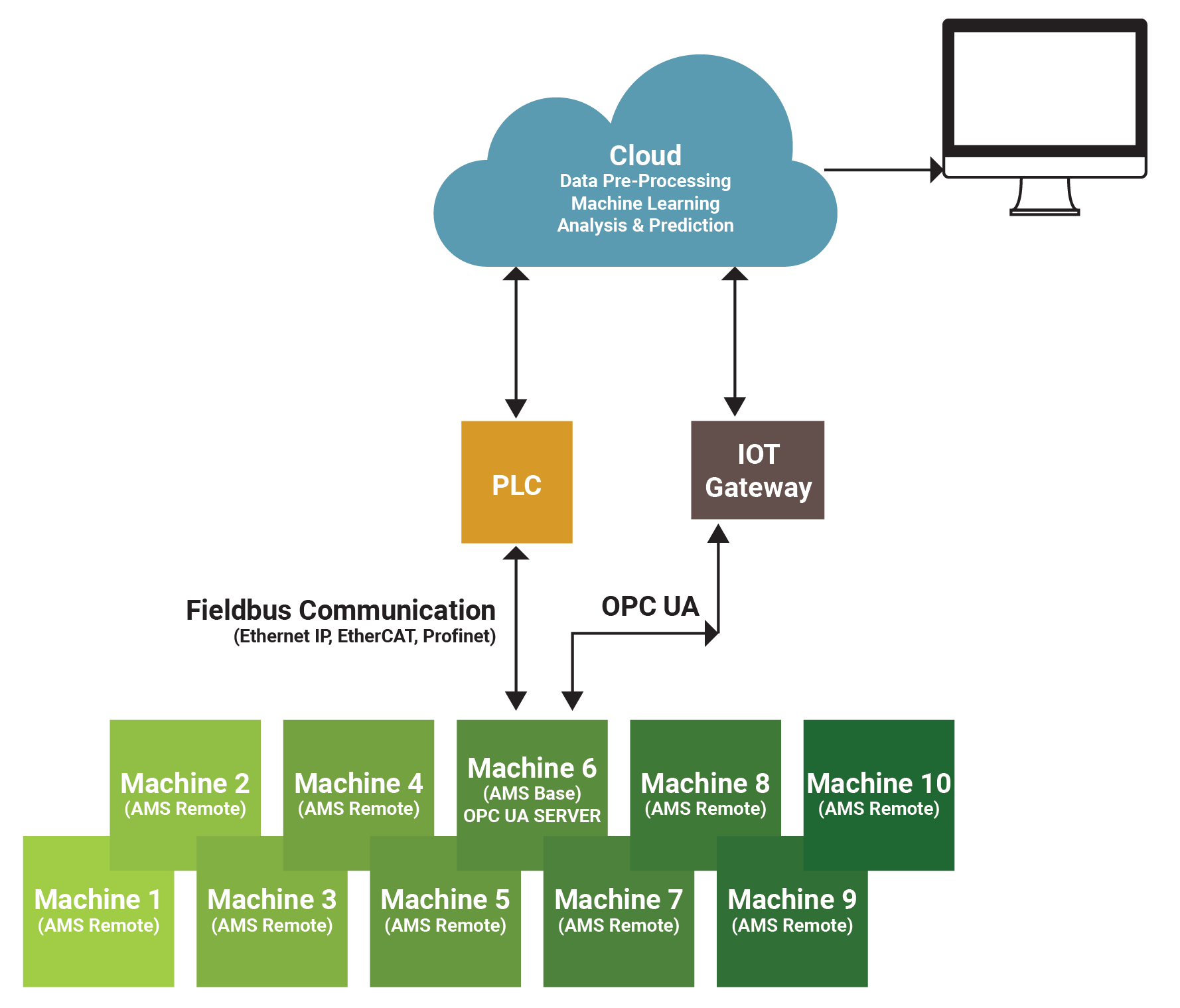

The AMS base unit had an integrated OPC UA server to facilitate data transfer. Compressed air pressure, flow, and temperature values were stored at 10Hz in an internal buffer and published to the supervisory control system at 1Hz via the integral OPC UA client. Data was simultaneously published to the machine’s controller (PLC), using an industrial fieldbus protocol (the device used supports PROFINET, EtherNet/IP, and EtherCAT). The eight wireless remote units (maximum of ten remote units possible within 100-meter radius), were paired with the AMS base units. This enabled a hybrid system wherein the PLC takes control of the real-time processes, and the data is communicated to the data cloud for analysis. The wireless remote units communicated with the base unit using a proprietary wireless protocol at the 2.4 GHz ISM (Industrial, Scientific & Medical) frequency band. The data generated by the AMS is high resolution, so fine details of a machine’s operation can be observed. With analytics software packages, high-resolution data can be used to detect air leakage, predict pneumatic component failures, build digital twins, and understand the machine’s efficiency more deeply.

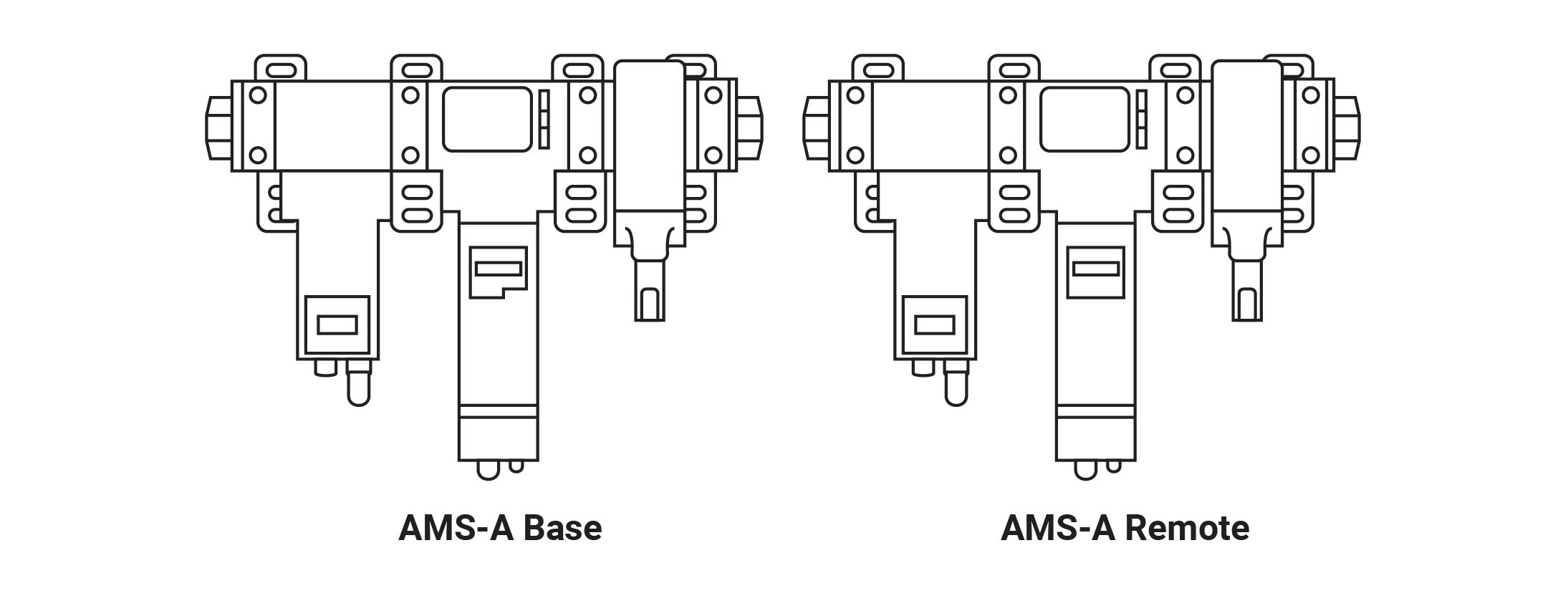

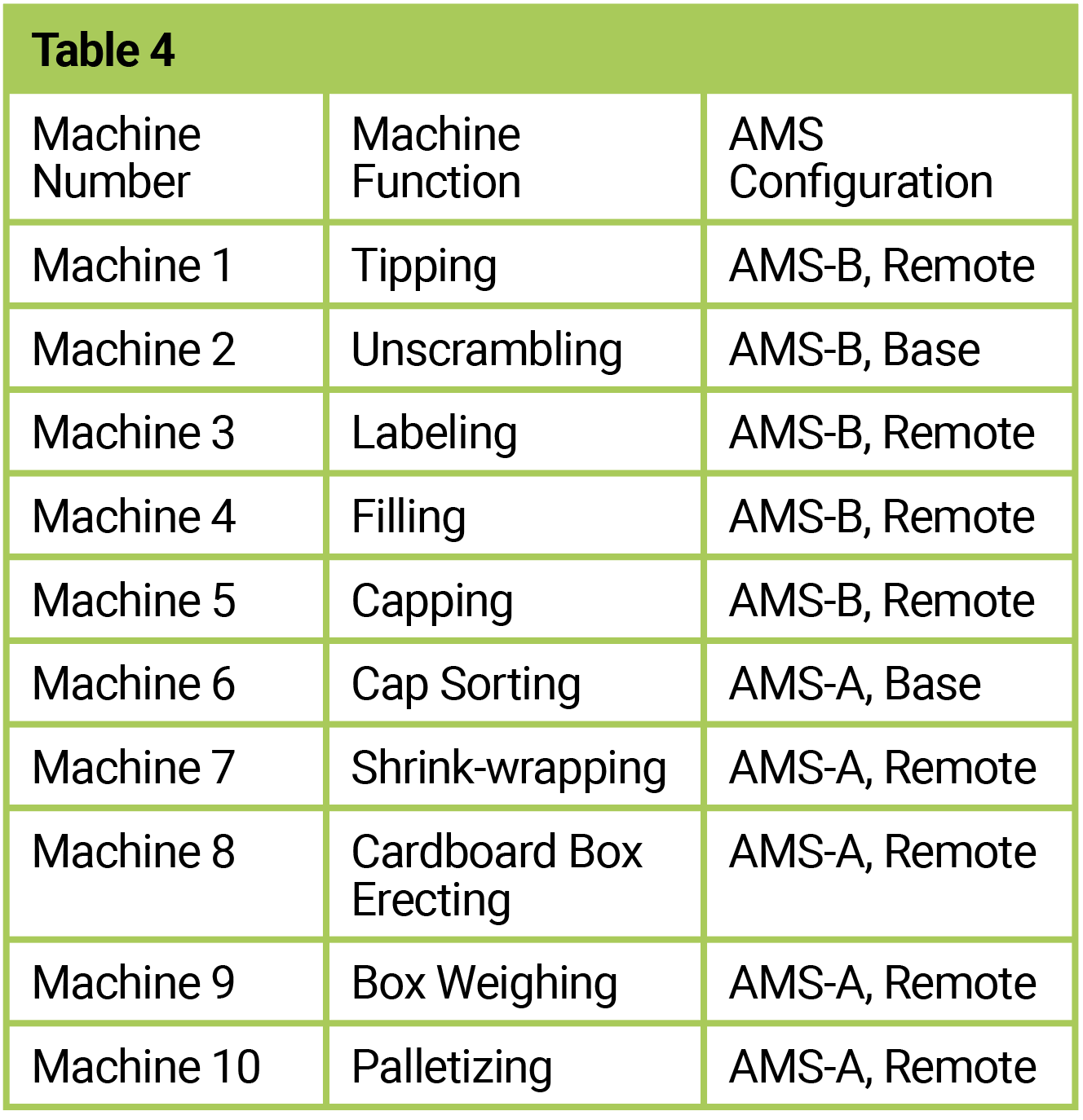

The AMS configurations used were as follows:

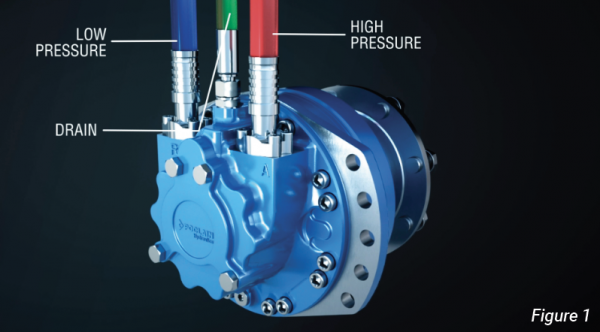

- AMS-A (see Figure 1)

- Electro-pneumatic pressure regulator

- AMS HUB – BASE

- AMS HUB – REMOTE

- Residual pressure relief valve

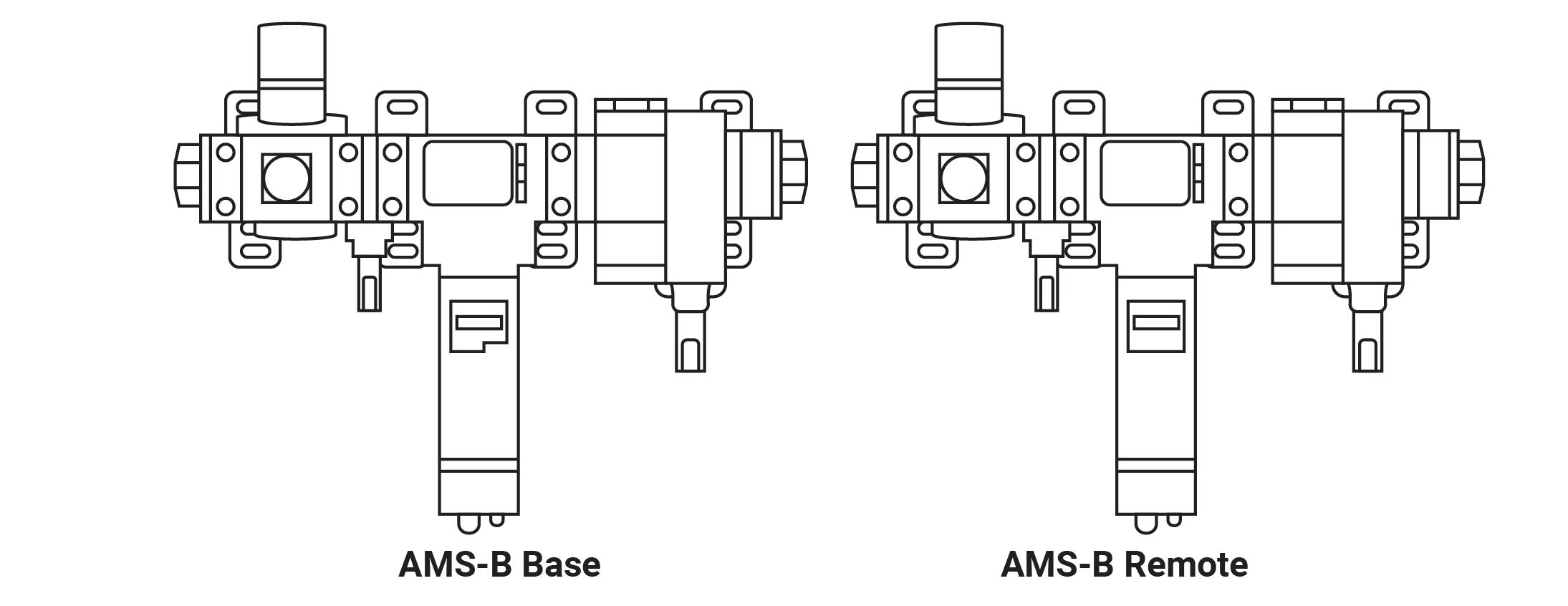

- AMS-B (see Figure 2)

- Manual pressure regulator

- AMS HUB – BASE

- AMS HUB – REMOTE

- Residual pressure relief valve with soft start

Figure 1

Figure 2

The AMS unit’s sustainability features include management of the machine’s operational mode, standby mode, and isolation mode. When the measured flow rate drops below a user-defined value, for longer than the user-defined time, and the machine’s digital input signal (24V DC) is ON (provided to the AMS HUB), the AMS reduces the output pressure (operating pressure setpoint) to the secondary, or stand-by, pressure setting (lowest feasible pressure setting on the machine). If the standby mode continues until a user-defined time, the isolation valve closes to exhaust the output pressure. From standby mode or isolation mode, the AMS’s output pressure is set to increase to the operational pressure mode when the standby input signal goes OFF (0 VDC), thus putting the machine back into Operation Mode. The AMS installed for our test was designed to replace the traditional filter/regulator unit for easy installation and maintenance. Its compact size took little additional space in the facility or on the machine, making it an attractive solution for users looking to improve their environmental performance without incurring significant installation costs.

The AMS unit’s sustainability features include management of the machine’s operational mode, standby mode, and isolation mode. When the measured flow rate drops below a user-defined value, for longer than the user-defined time, and the machine’s digital input signal (24V DC) is ON (provided to the AMS HUB), the AMS reduces the output pressure (operating pressure setpoint) to the secondary, or stand-by, pressure setting (lowest feasible pressure setting on the machine). If the standby mode continues until a user-defined time, the isolation valve closes to exhaust the output pressure. From standby mode or isolation mode, the AMS’s output pressure is set to increase to the operational pressure mode when the standby input signal goes OFF (0 VDC), thus putting the machine back into Operation Mode. The AMS installed for our test was designed to replace the traditional filter/regulator unit for easy installation and maintenance. Its compact size took little additional space in the facility or on the machine, making it an attractive solution for users looking to improve their environmental performance without incurring significant installation costs.

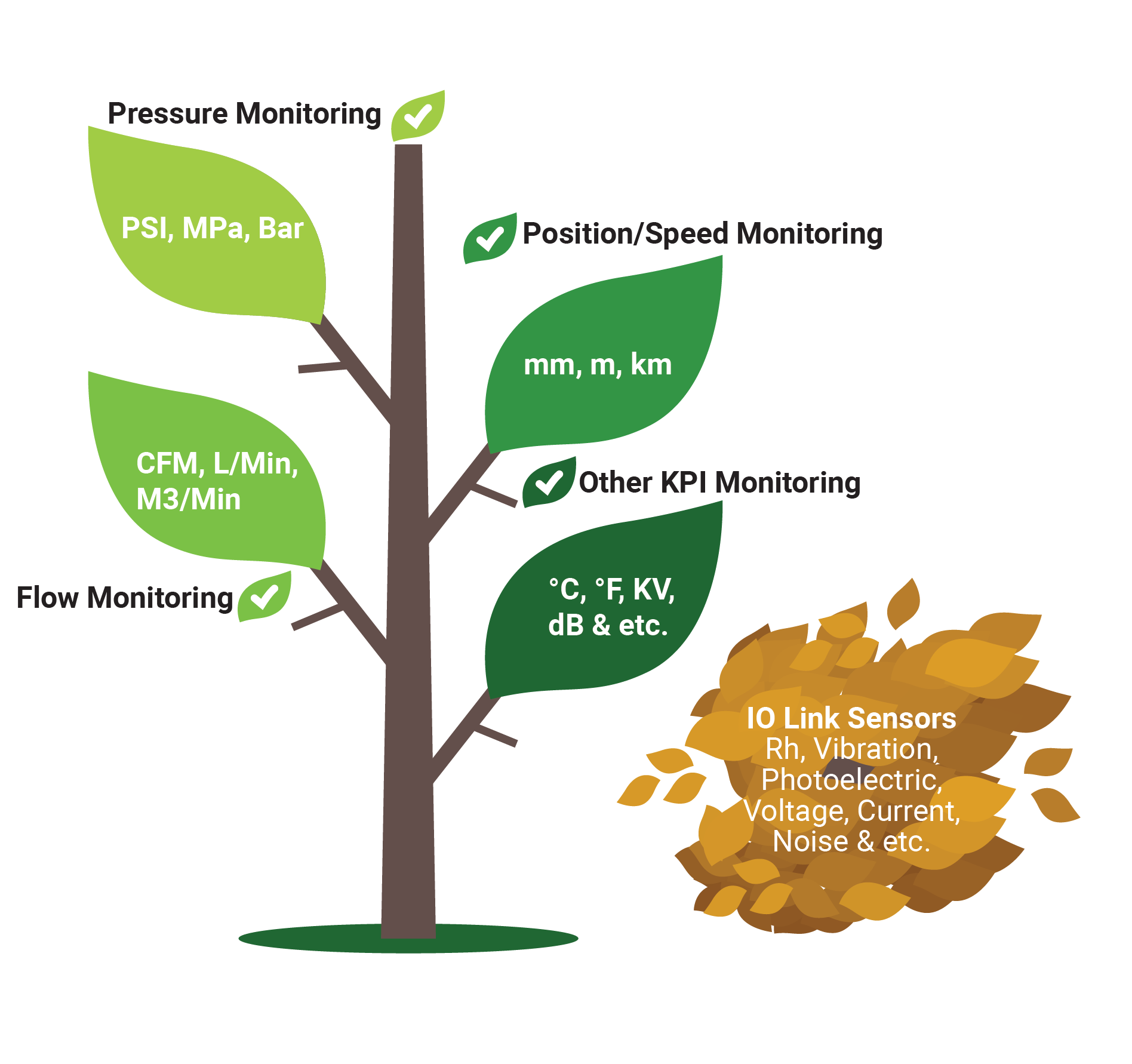

AMS & IO-Link

Connected devices are gaining importance for their increased capability, easy configuration, and the ability to change parameters while the system is running, providing higher resolution data for enhanced operations. The AMS was developed to simplify and standardize device wiring and installation. IO-Link compressed air pressure, flow, and temperature sensors were built into the AMS HUB. In addition, the AMS included a web-based configuration tool to set the parameters of the AMS unit. Although not used in the initial case study, the AMS unit was able to support an additional IO-Link sensor (such as dewpoint or vibration) that could be connected to the AMS HUB. Figure 3 shows a Digital Ecosystem where IO-Link devices are connected and monitored using an Air Management System (AMS) in a star topology network.

AMS & OPC UA

Manufacturers across the world are prioritizing the need to digitize factory data. The advent of Industry 4.0 has driven the manufacturing environment towards machine-to-machine communication or machine-to-cloud communication to make improved production decisions. This makes OPC UA the world’s most popular standard for open automation data connectivity, since it is manufacturer, platform, and programming language independent. With built-in security mechanisms, OPC UA avoids the use of Distributed Component Object Model (DCOM) and eliminates translation middleware. The AMS does not require the use of an “Edge Computing” device but will work with architectures that utilize them. Innovative technologies and methodologies such as new transport protocols, security algorithms, encoding standards, or application services can be incorporated into OPC UA while maintaining backward compatibility for existing products. OPC UA products built today will work with future products. The Air Management System in our test had an embedded OPC UA server which provided secure data connectivity to directly integrate into the client’s enterprise network.

Case Study | Baseline Conditions

Production line

Ten machines were configured in the bottle filling line. The machines were numbered from 1-10 in the order of the production process; the functions of the machines were:

- Machine 1 – Bottle tipping

- Machine 2 – Bottle unscrambling

- Machine 3 – Labeling

- Machine 4 – Filling

- Machine 5 – Capping

- Machine 6 – Cap sorting

- Machine 7 – Shrink-wrapping

- Machine 8 – Cardboard box erecting

- Machine 9 – Box weighing

- Machine 10 – Palletizing

The annual operational hours of the facility were 8,760:

- 60 % – Production mode

- Product made

- 38% – Idle mode

- No product made

- Machines at full pressure

- 2% – Isolation mode

- Machines at no pressure

Operation

In the typical production process, bottles are unloaded and tipped into a drum. A conveyor carries the bottles from the drum and drops them into an unscrambler. The bottles are set upright, loaded into pockets on a conveyor, and moved toward the filling machine. The product is dispensed and caps from the cap sorting machine are indexed in the capping machine using air nozzles. The capping machine applies the caps and seals the bottles. The bottles move toward the labeling machine wherein labels are applied, and a group of bottles is then shrink-wrapped before being transferred to boxing. Simultaneously, cardboard boxes are erected at the respective machine and the wrapped bottles are placed in the boxes. A box-weighing machine compares the box’s weight to the standard and pneumatically rejects those that are out of compliance. The box then moves to the palletizing station where a group of boxes are shrink-wrapped on a pallet.

Every action on every machine is pneumatically driven and involves the use of a plethora of pneumatic components. Any mishap in the process or a machine waiting (idle mode) for the product to arrive still consumes compressed air in terms of leaks or blow- offs.

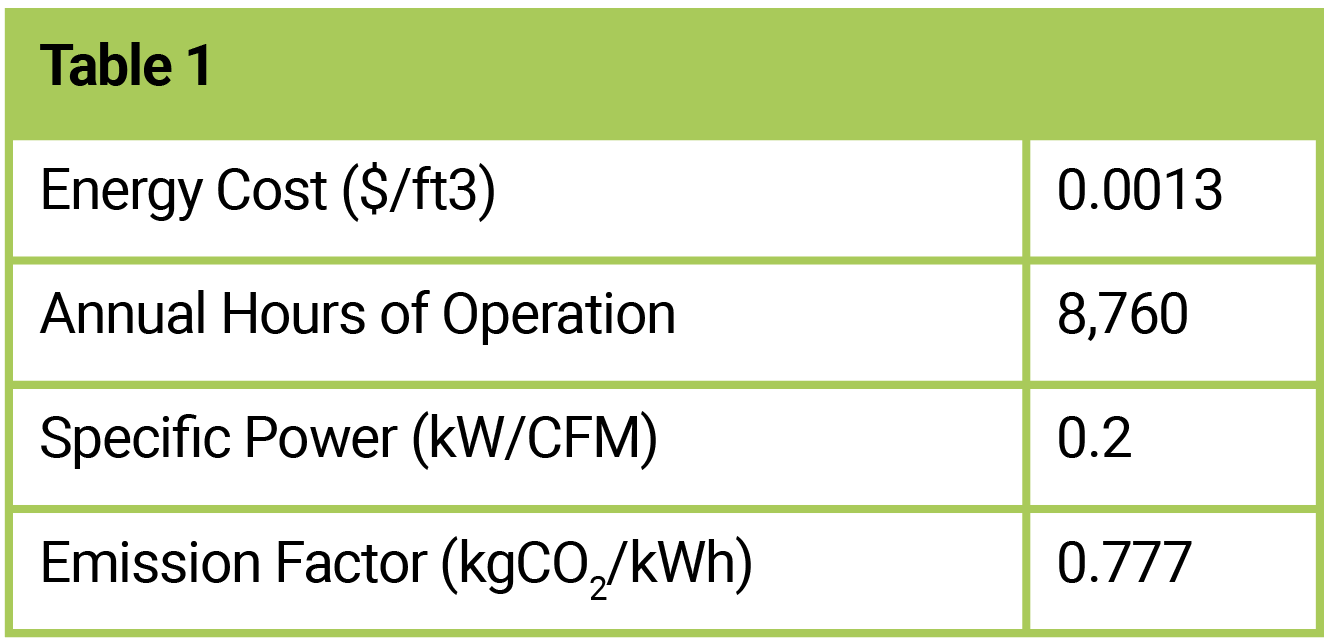

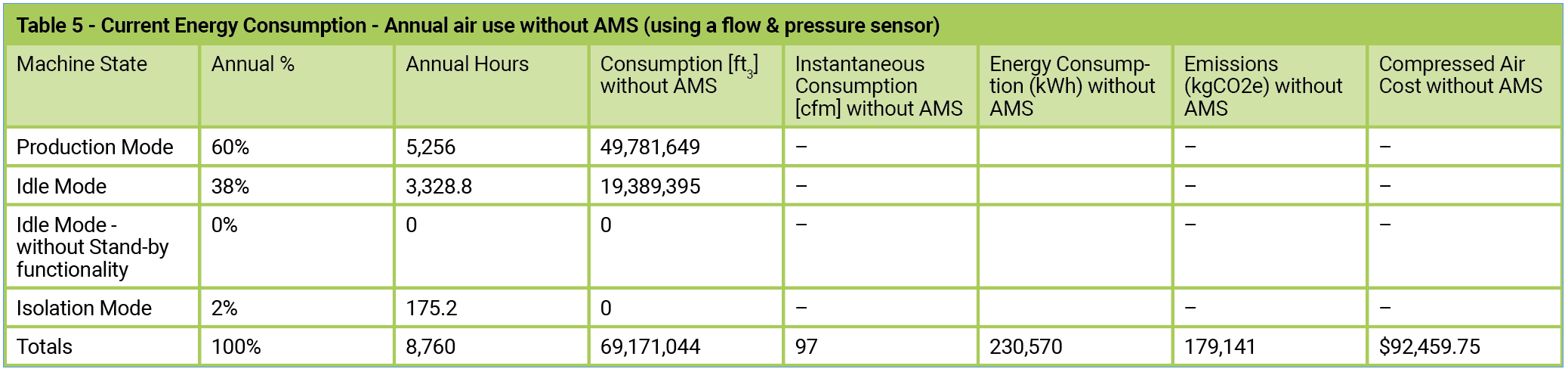

To estimate energy savings and carbon emission reduction for any given system, it is important to consider:

- The specific power consumption of the compressors (kW/CFM)

- The compressed air energy costs ($/kWh)

- The CO2 emission factor (kgCO2/kWh) The annual hours of operation (see Table 1)

The target for compressed air cost reduction is typically the “Idle-mode air consumption,” which includes the machine’s internal leakage, air used for blow-offs, air used to cool electric motors and electrical cabinets, and other pneumatic functions. Also of concern are the machine’s pressure set points, average, maximum and minimum flow rates, and any fluctuations.

Instrumentation

The activity began with selecting and installing the instrumentation required to measure the compressed air pressure and flow to understand the machine’s air consumption.

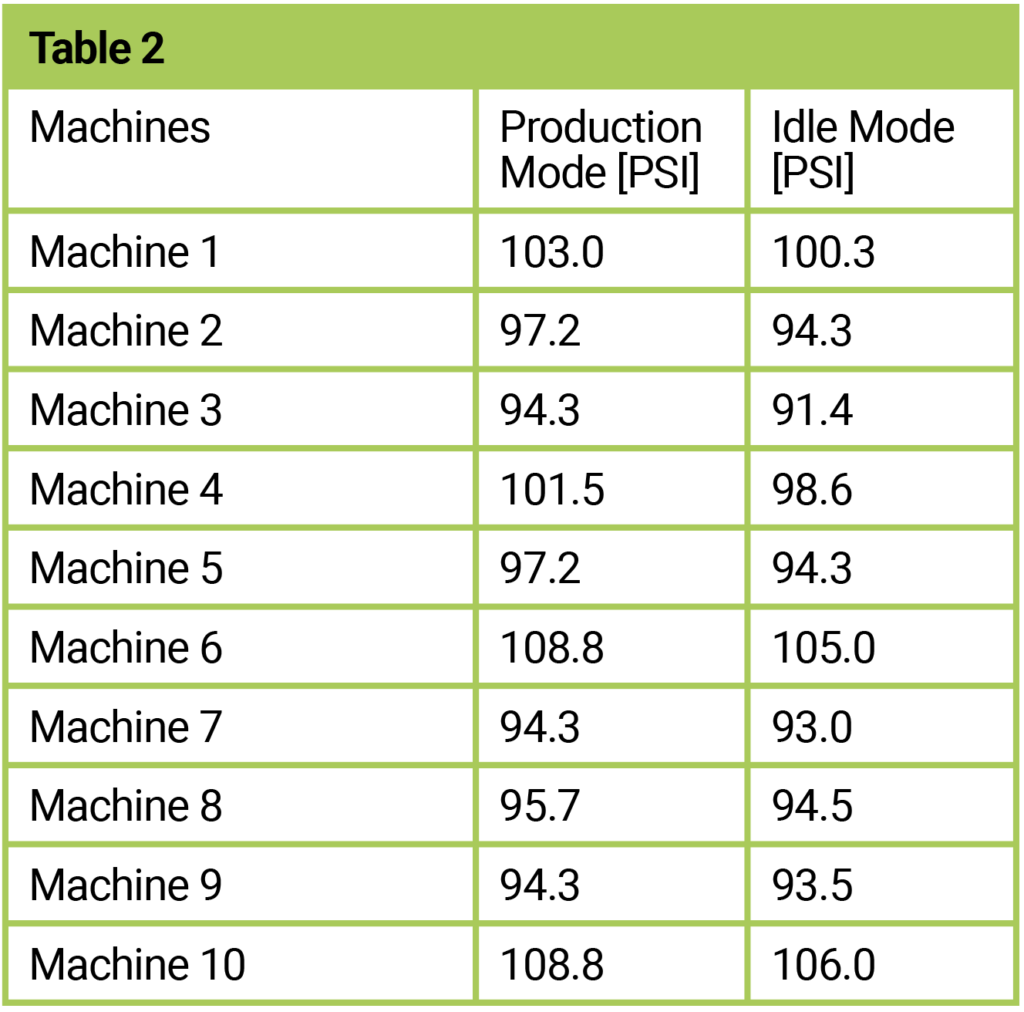

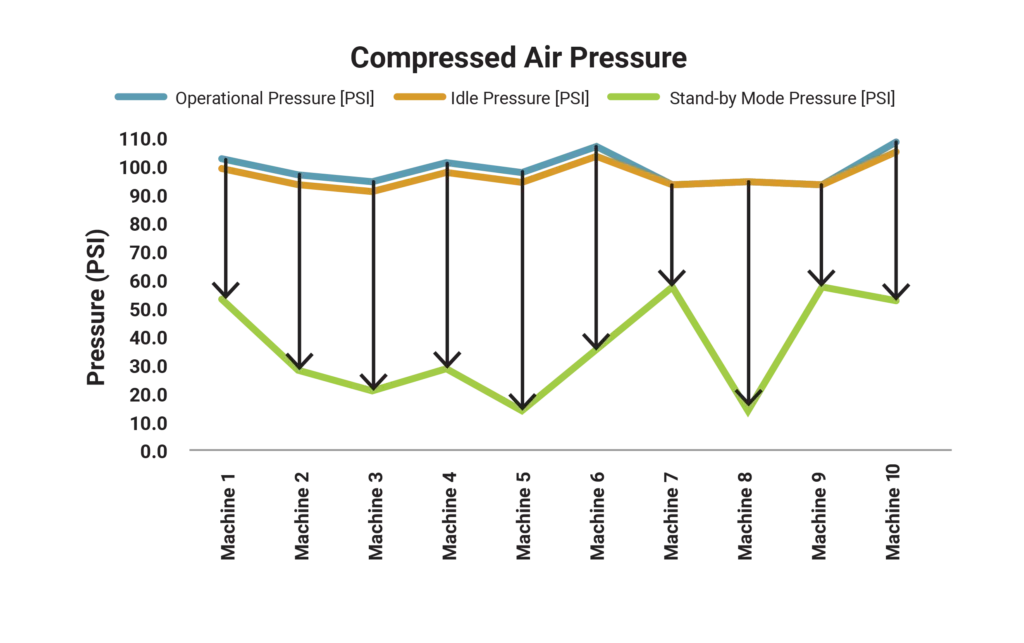

Pressure and flow measurements

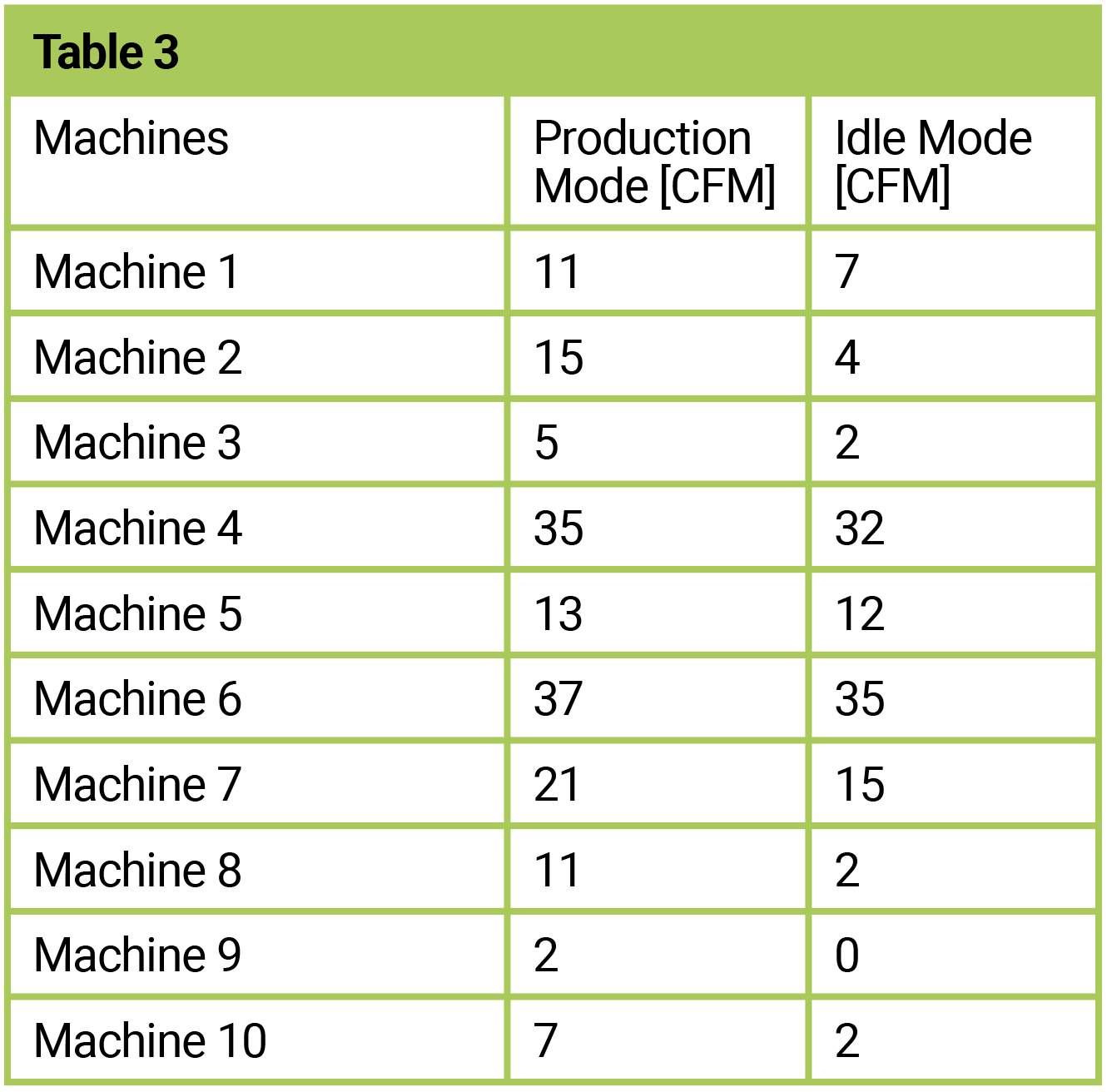

Each machine had a 1-inch air inlet pipe to the machine. Compressed air flowed from left to right through an appropriately sized air preparation unit with a manual residual pressure relief valve. In-line flow meters and pressure sensors were installed at the air inlet of all 10 machines. The air flow and pressure data was obtained using proprietary data loggers. Table 2 shows the pressure readings on the machines when in production mode and in idle mode. Table 3 shows the flow readings on the machines when in production mode and in idle mode.

AMS installation

Figure 5

The AMS units evaluated had an Ingress Protection (IP) rating of 65, which eliminated the need for a protective enclosure. They were installed as shown in Table 4.

Other installation considerations included:

- Digital integration of the AMS units

- Communication cable (M12 -RJ45 Ethernet cable) to connect the AMS base unit to a network switch and assign an IP address.

- Supplying 24V DC power to the AMS units from the host machines

- Machine input signals for activating standby and isolation modes. In this case, a digital signal that provided the machine state was used to activate standby mode and isolation mode. IIoT architecture, as shown in Figure 4.

- Embedded OPC UA server

- IoT gateway – with OPC UA client

- Data cloud – for data processing

- Data visualization software

- Creation of OPC UA tags, so that the OPC UA clients can access the pressure and flow data

Figure 4

Figure 5

Results and Discussion

Reducing energy consumption during idle mode to first establish the baseline performance, we measured the compressed air pressure and consumption on all ten machines in the production line. As expected, there was no significant reduction in pressure or air consumption by the machines during idle mode.

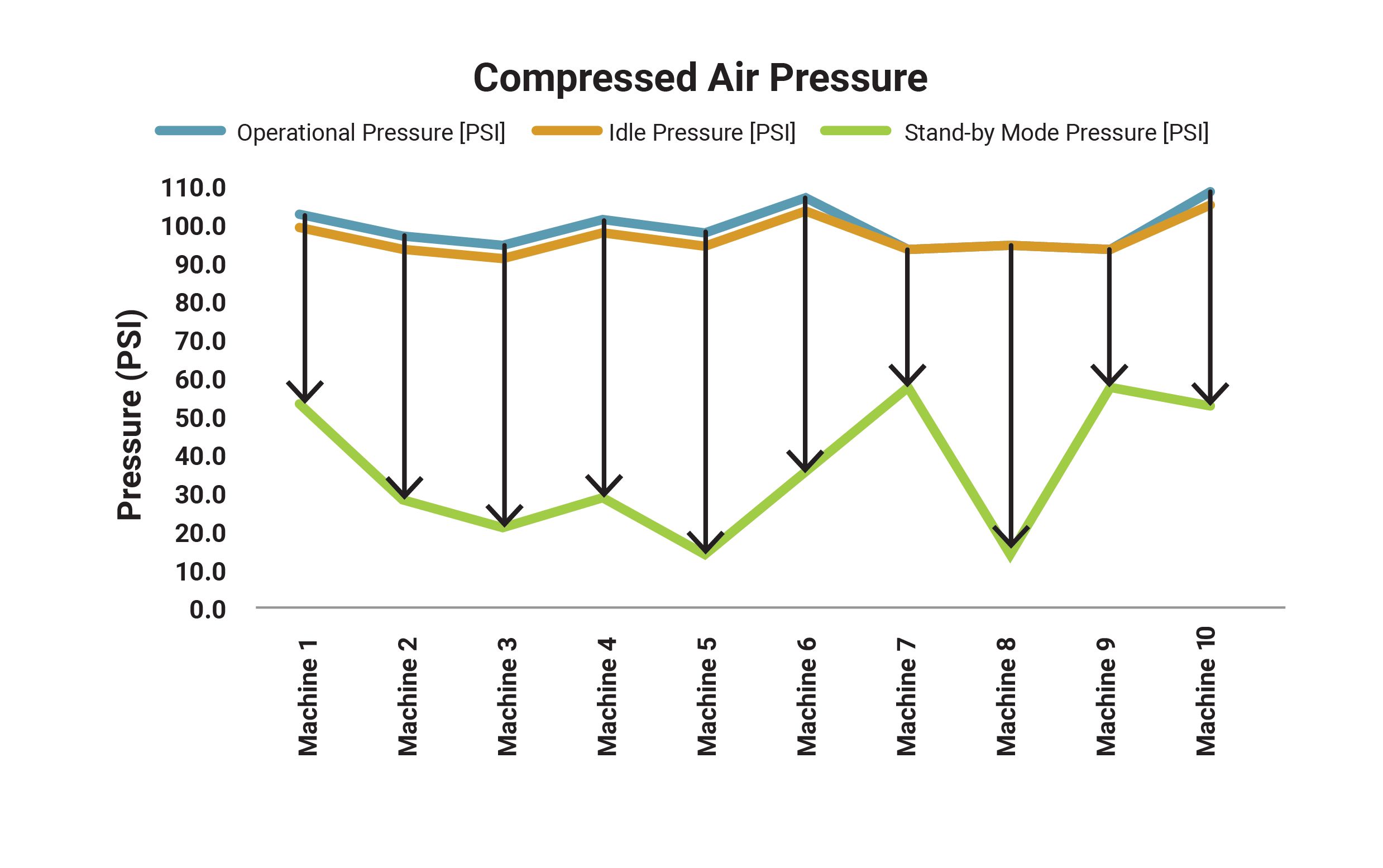

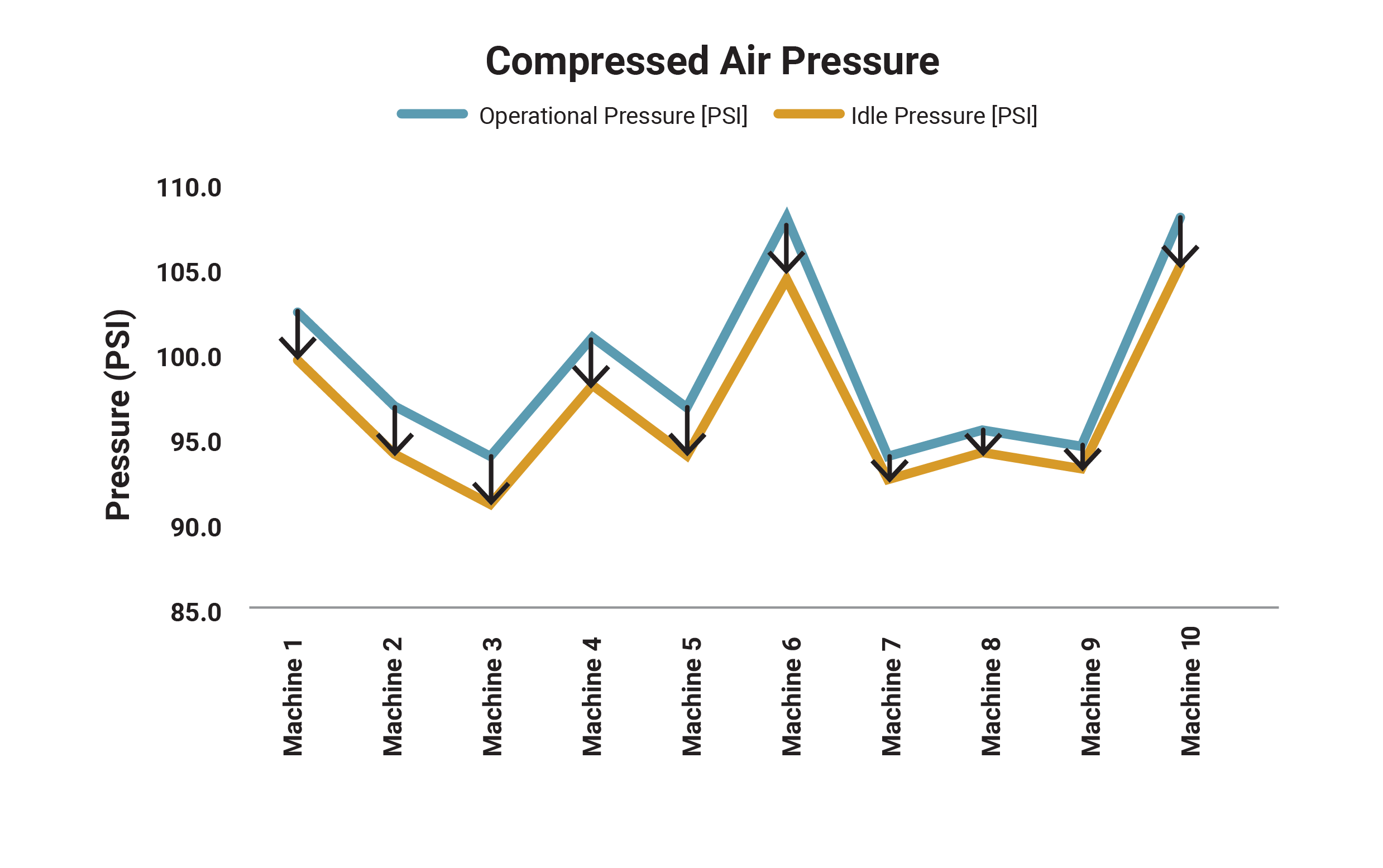

The average pressure reduction between the production mode and idle mode in the entire line, as observed in Figure 5, was 2%.

After the installation of the AMS units on the machines, the data was thoroughly analyzed by the client’s proprietary data visualization software. The AMS units semi-automatically reduced the pressure supply on the machine during the traditional machine idle mode by activating the standby mode. The user defined the secondary pressure (or the standby mode pressure) and the threshold flow on the AMS web configurator after understanding the basic pressure and flow requirements, and pneumatic functions of the machine. It is evident in Figure 6 that the average pressure reduction for the production line, because of standby mode, was 63%.

Figure 6

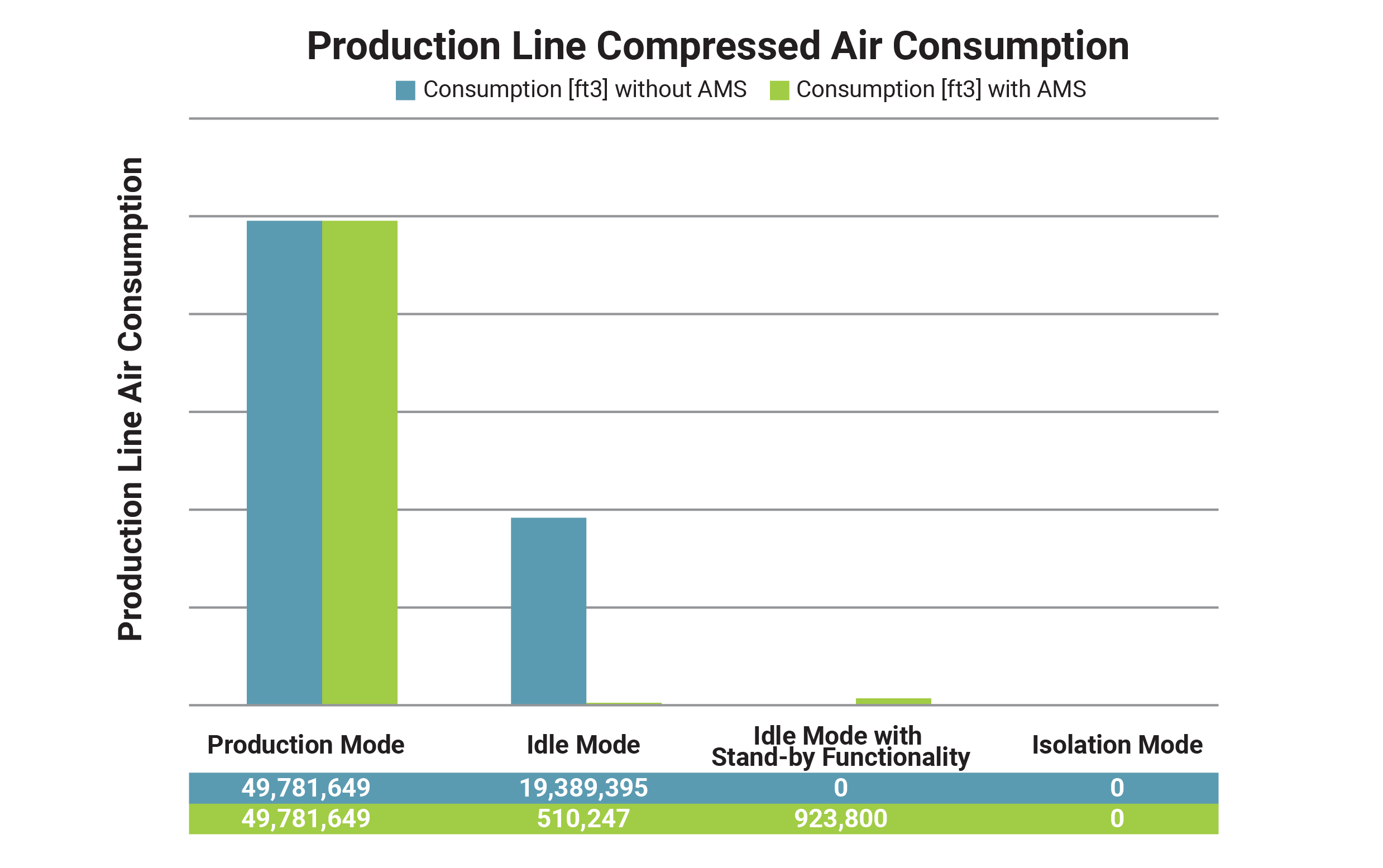

There were no changes to productivity, and no changes made to the machine’s normal operation when in production mode. The machines benefit from standby and isolation mode functionalities only when production is stopped. The significant pressure reduction contributes to the significant decrease in air consumption. The activation of the standby function during the machine’s idle mode significantly reduced the artificial demand that existed otherwise. As the machines switched into isolation mode, there was no consumption, as shown in Figure 7.

Figure 7

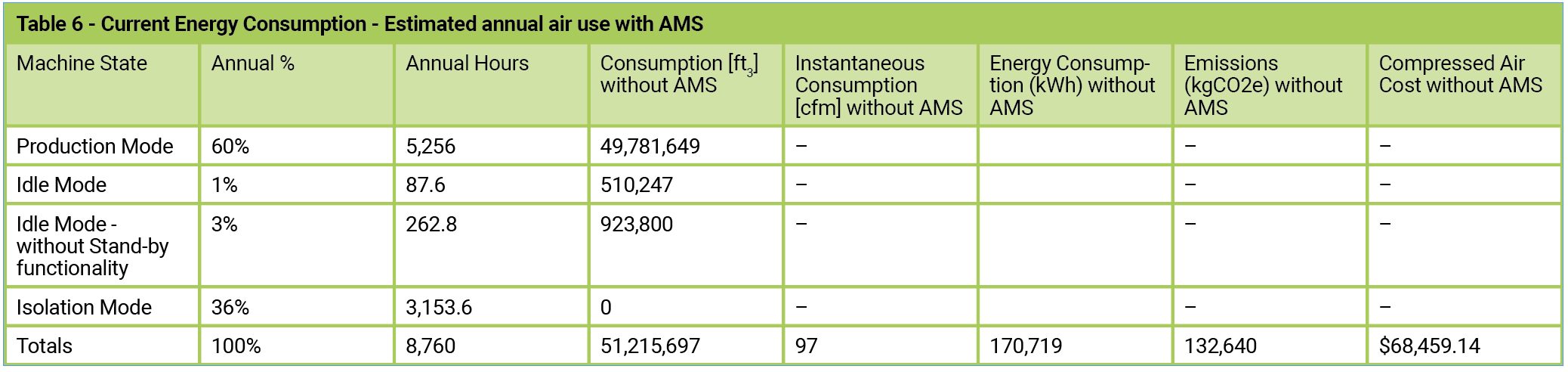

Table 5 and Table 6 (below) show a 26% decrease in annual power consumption (from 230,570 to 170,719 kWh) in the entire production line, realized by installing an AMS and taking full advantage of the standby mode and isolation mode functionalities. The savings were realized by switching the production line into isolation mode 36% of the year, as compared to the previous state in idle mode (paused under full pressure) 38% of the year. The cost-saving calculation (see Table 7 below) subtracts the annual cost of air after the installation of the Air Management System from the annual cost of compressed air before the installation of the AMS.

- $ = (annual consumption [ft3]) × (USD/ft3)

- ROI = (total investment) / (annual cost savings)

- kWh = [(kW/CFM) × 60] × (ft3)

- Emission reduction = (kgCO2/kWh) × (kWh)

- $ = annual cost

- Ft3 = annual air consumption

- USD/ft3 = cost / cubic foot

- kW/CFM = specific power

- kWh = annual energy savings

- kgCO2/kWh = emission factor

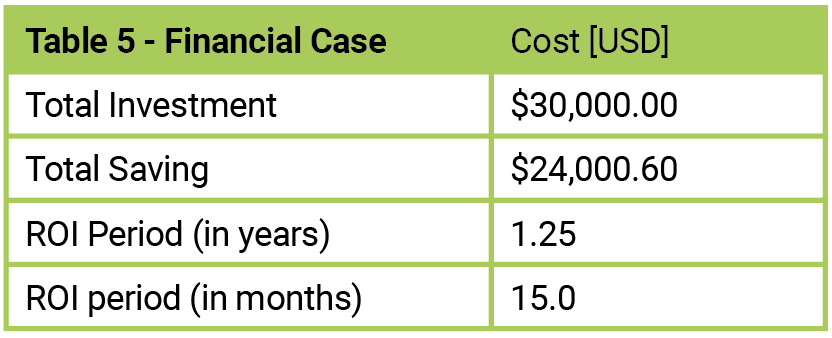

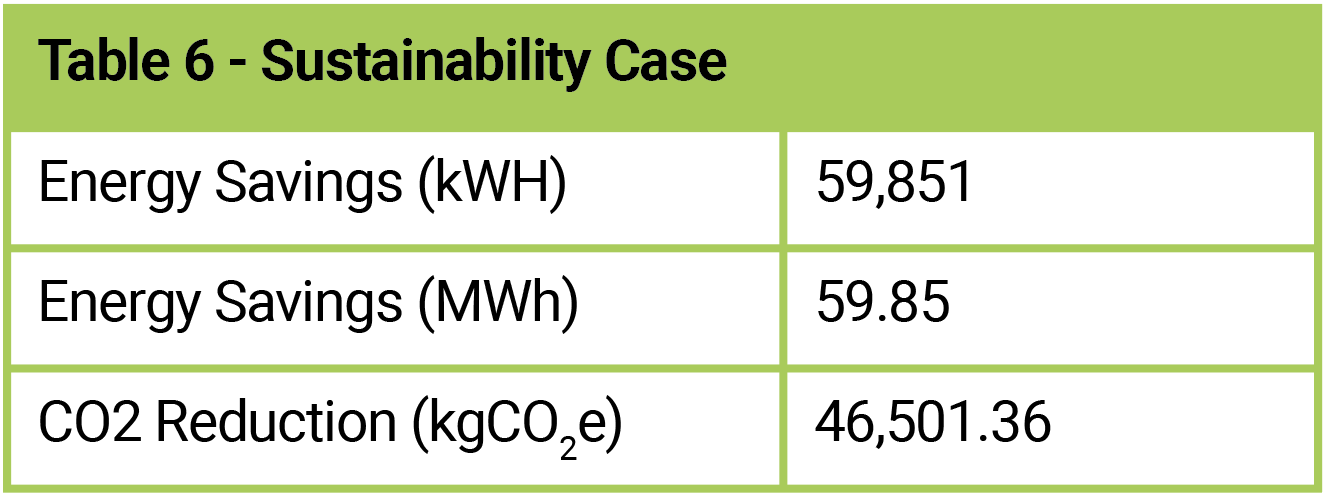

Value proposition

It can be seen from Table 7 and Table 8 below that the value of the Air Management System (AMS), just based on the energy savings proposition, generated a return on investment (ROI) of just over one year. Of course, the savings will be specific to each application, and can vary widely due to the flow rate of each individual machine. Gathering baseline data and prioritizing those machines or production lines that have the potential to generate a good return on investment is always a sound strategy.

Conclusion

Although alluded to above, it is beyond the scope of this paper to quantify the additional cost savings and efficiency gains to be realized by utilizing the data generated by a sophisticated monitoring system (AMS).

Although alluded to above, it is beyond the scope of this paper to quantify the additional cost savings and efficiency gains to be realized by utilizing the data generated by a sophisticated monitoring system (AMS).

Consider, however, that an AMS can provide real-time pressure and flow data on each machine. That data can be used to identify future maintenance needs before machine or line stoppage occurs. At minimum, a data collection system can be set to provide an alarm when the average flow or pressure increases beyond an established baseline level, signaling the need for inspection of the machine during the next scheduled maintenance window.

An improvement to the above scenario would employ a Supervisory Control and Data Acquisition (SCADA) system to “watch for outliers” and compare those to the baseline data, again signaling the need for maintenance (data analytics). Even more granularity

could be achieved by employing artificial intelligence (AI) to map the pressure and flow data against a machine’s motion profile. In such an instance, an increase in flow at a particular timestamp could be used not only to identify that a leak was developing, but to specify which portion of the circuit was beginning to fail. Then the repair parts could be ordered in advance, and the maintenance scheduled when convenient.

Each of the possibilities outlined above can provide the data necessary to perform predictive maintenance, with the end goal being little or no unscheduled downtime. Unfortunately, the cost avoidance of unscheduled production delays is difficult to calculate from the outside. It is certain that every manufacturing facility has an internal “cost of lost production” for every hour that production is halted. These costs are often significant.

From an enterprise perspective, there is also value in “digitalization.” Comparing like machines in separate locations and getting a sense of productivity at an enterprise level also has significant value.

Additional Takeaways

Significant energy savings in pneumatic systems can be realized by monitoring and semi- automatically regulating and isolating compressed air.

An Air Management System (AMS) can reduce the artificial demand for compressed air during periods of non-production.

A controlled pressure ramp function avoids sudden “pneumatic jerks” when restoring the compressed air supply to the machine.

Potential problems due to electrical control issues will not affect the pneumatic system since an AMS that operates “Normally Open (NO)” can be Selected.

Flow Consumption by the machines in the production line can be converted to energy (kWh), and energy cost ($) and be correlated to production metrics, viz., understanding the energy consumption per item produced, the cost of defective product, the cost per shift due to waste, and thereby optimize production processes.

The extra IO-Link port on the AMS can be utilized for vibration sensors, vision sensors, dewpoint sensors, etc., to gather data on critical process variables.

Pressure, flow, temperature, and other process variables can be monitored to establish baseline conditions for machines and other consumers of compressed air. If operation conditions change, preventative action can be taken by the now informed user.

The high-resolution data provided by an AMS can enable the benchmarking of machines and factories. Users can compare machines to learn from them and implement best practices company- wide.

Installing an AMS (Figure 8) on a machine’s pneumatic system and evaluating the air consumption on the machine leads to optimized air consumption, increased life of pneumatic components, and improved production process- related decision-making.