The Impact of Smart Manufacturing on Maintenance Practices

By Eric Whitley.

Defining Smart Manufacturing

The shift towards smart manufacturing is pivotal in the evolution of the fluid power industry, shaping how hydraulic and pneumatic systems operate. A closer look at what smart manufacturing encompasses is instrumental in understanding this transition’s depth and potential.

Smart manufacturing is primarily an umbrella term, encapsulating various technologies and methods that use data, machine learning, and interconnected systems to optimize and refine manufacturing procedures. It signifies the amalgamation of IIoT — a network of devices furnished with sensors and software for data collection and exchange — with the analytical prowess of AI and big data.

In fluid power systems, these technologies endow hydraulic and pneumatic mechanisms with heightened autonomy and intelligence, fostering real-time monitoring and proactive maintenance. This combination — IoT, AI and big data — transforms the approach to maintenance through smart manufacturing, driving the industry towards predictive maintenance and beyond the traditional reactive measures.

The Shift from Reactive to Predictive Maintenance

A defining feature of smart manufacturing in the fluid power industry is its transition from reactive to predictive maintenance. Traditional reactive maintenance has long been the norm in the industry. However, it carries with it inherent inefficiencies and risks, including equipment downtime and the potential for cascading failures.

Predictive maintenance, in contrast, seeks to prevent these issues by identifying potential problems before they occur. This approach leverages the power of IoT sensors embedded in hydraulic systems, which collect real-time data on a multitude of parameters, such as pressure, temperature, and flow rate. This wealth of data is then processed by AI algorithms, which can identify subtle patterns and anomalies indicating system failures. In essence, predictive maintenance allows fluid power professionals to address issues proactively, optimizing the performance and lifespan of the hydraulic and pneumatic systems under their care, while minimizing disruptive and costly unexpected failures.

Impact on Efficiency and Performance

The benefits of predictive maintenance in smart manufacturing are multifaceted, with significant improvements in efficiency and performance being most noteworthy. In the hydraulic and pneumatic systems of the fluid power industry, uninterrupted operation is key to productivity. Predictive maintenance harnesses the continuous data stream from IoT sensors to optimize the system performance, identifying signs of potential failure long before they escalate into actual problems.

This ensures timely corrective measures, drastically reducing system downtime and enhancing operational efficiency. An example is the implementation of predictive maintenance in an industrial pneumatic system. Historical data showed that the system was prone to unexpected pressure drops, leading to unscheduled halts in production. Using AI-driven predictive analysis, engineers were able to predict these events before they occurred, managing to reduce system downtime by 30%. This case underlines the transformative effect of smart manufacturing and predictive maintenance on fluid power systems.

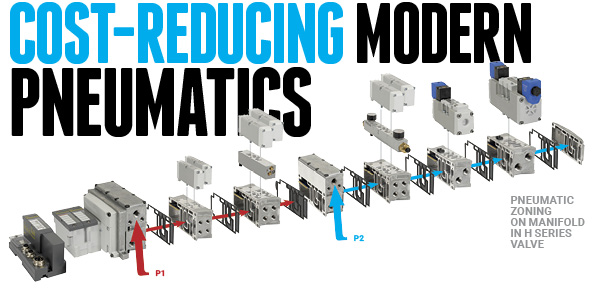

Financial Implications and Cost Reduction

The implementation of predictive maintenance in smart manufacturing also has significant financial implications. It can lead to considerable cost reductions primarily by minimizing unscheduled downtime and reducing the losses associated with interrupted production. However, the cost of implementing these technologies must also be factored into the equation.

The initial investment may be substantial, but when balanced against the cost savings achieved, the return on investment becomes clear. Furthermore, the efficiency improvements offered by predictive maintenance lead to lower energy consumption, contributing to further cost savings. Therefore, despite the upfront costs, the financial implications of embracing smart manufacturing are predominantly positive, promising long-term profitability for fluid power operations.

Enhanced Safety and Compliance

Another significant impact of smart manufacturing and predictive maintenance is the enhancement of safety and compliance. This is primarily achieved by reducing the risks associated with unexpected equipment failure, which can lead to accidents and safety hazards.

Sensors and AI can monitor for irregularities or deviations in performance that, if unaddressed, could result in component failure and potentially hazardous situations. Through early detection, necessary maintenance can be scheduled proactively, thereby ensuring a safer working environment.

Moreover, smart manufacturing tools also facilitate compliance with industry regulations and standards. Detailed, real-time data simplifies audit processes and compliance reporting. This offers fluid power engineers and technicians greater confidence in their regulatory compliance and adherence to industry standards. Therefore, predictive maintenance not only ensures the smooth operation of hydraulic and pneumatic systems but also contributes to safer work environments and easier regulatory compliance.

Changing Roles of Fluid Power Professionals

Smart manufacturing is reshaping the roles and skills required of engineers and technicians in the fluid power industry. Traditional roles, often centered on reactive troubleshooting and repairs, are evolving to incorporate elements of data analysis, machine learning, and systems networking.

The shift to predictive maintenance necessitates a new proficiency in interpreting sensor data and recognizing patterns that may indicate potential system failures. Professionals in the field must now be comfortable with a range of technologies that underpin smart manufacturing.

As part of this digital transformation, fluid power professionals must also enhance their knowledge of regulatory standards related to digital data security and privacy. With hydraulic and pneumatic systems increasingly interconnected and generating vast amounts of operational data, ensuring the integrity and security of this data is paramount.

Yet, despite the changes, the fundamental principles of fluid power systems — hydraulics and pneumatics — remain at the heart of the industry. Understanding these principles enables a more effective application of new technologies like predictive maintenance, which helps plants reap the full benefits of smart manufacturing. A combination of traditional engineering skills and a strong understanding of emerging technologies is what positions fluid power professionals to excel and drive their industry forward.

Challenges and Solutions

As with any significant technological transition, there are challenges that the fluid power industry faces in adopting smart manufacturing. Foremost among these is the initial investment required to upgrade to IoT-enabled machinery and systems. The complexity of new technologies also presents a steep learning curve for engineers and technicians accustomed to traditional systems.

Another significant challenge is workforce training. The shift to smart manufacturing requires not just the understanding of physical systems but also skills in data analysis and interpretation and the ability to manage digital tools and connected work platforms. This calls for considerable upskilling and continuous learning, which can be time-consuming and resource-intensive.

However, these challenges should not deter the industry’s progress towards smart manufacturing. Solutions are emerging that can help mitigate these issues. For instance, the cost and technical complexities can be managed through a phased approach. When smart technologies are integrated gradually, the costs can be spread over time, reducing the impact of initial implementation.

For workforce training, partnerships with educational institutions can be forged to provide the necessary training and skill development. Alternatively, online platforms offer many courses tailored for smart manufacturing. Real-world case studies, such as those from the automotive and aerospace industries, provide evidence of successful smart manufacturing implementation and can serve as valuable guides.

Looking to the Future:

Predictive Maintenance and Beyond

As the fluid power industry moves confidently into the era of smart manufacturing, it’s crucial to consider the potential future trends in maintenance and the implications of these trends on the industry. Predictive maintenance has already sparked a significant transformation, but further evolution is inevitable with ongoing technological advancements.

Machine learning algorithms, for example, are continually improving and becoming more adept at interpreting vast amounts of data from IoT devices. They will likely become more proficient at predicting failures, minimizing downtime, and maintenance costs. This may lead to the emergence of prescriptive maintenance, where systems don’t just predict failures but also suggest the best corrective action, providing an even more proactive maintenance approach.

Similarly, the integration of AR in maintenance practices could enhance the accuracy and speed of repair operations. With AR, technicians could have real-time access to detailed technical information, visual guides, and even remote expert assistance, all while working on the machinery.

On the data front, we could see an increased use of edge computing, where data processing occurs close to the source of data generation. This approach can reduce latency and improve real-time decision making, further enhancing the efficiency of predictive maintenance systems.

These prospective advancements, while exciting, will carry their own challenges and implications. For instance, the further we delve into AI and machine learning, the more critical data security and privacy will become. Furthermore, as systems become more complex, so too will the necessary skills and expertise required of our engineers and technicians.

Yet, if the fluid power industry navigates these developments with the same tenacity and forward-thinking approach as it has thus far, there’s no doubt it will continue to realize the immense potential of smart manufacturing. This will not only reinforce the industry’s resilience and adaptability but also its crucial role in the broader manufacturing landscape.

Conclusion

The integration of smart manufacturing in the fluid power industry has transformed maintenance practices. This shift from reactive to proactive predictive maintenance is significant, addressing efficiency, performance, and safety while reducing costs and ensuring compliance. This transformation is crucial for remaining competitive in a rapidly advancing technological era. Engineers and technicians play a vital role as their roles evolve in response to these changes.

Embracing the challenges of smart manufacturing has allowed the industry to grow and advance. Future trends will continue to drive evolution in maintenance practices, underscoring the importance of learning and adaptation for industry professionals. Smart manufacturing is a testament to the industry’s innovation and adaptability.

After an extensive career as a reliability and business improvement consultant, Eric joined L2L, where he currently serves as the Director of Smart Manufacturing. His role in this position is to help clients learn and implement L2L’s pragmatic and simple approach to corporate digital transformation.

Eric lives with his wife of 35 years in Northern Utah. When Eric is not working, he can usually be found on the water with a fishing rod in his hands.