Understanding the Selection Process of a Pressure Control Valve

Pressure control valves are sensitive to the direction of flow. For example, flow cannot pass through a relief valve from T to P. Some pressure control valves, such as sequence valves, pressure reducing valves, and load holding/load control valves (counterbalance, holding, over-center, and brake valves) are located in circuits between the directional control valve and the actuator. In order to allow reverse flow around the pressure control section of the valve, these valves include reverse free-flow check valves. If the valve is installed incorrectly (backwards), the desired actuator control will not be achieved.

When choosing a pressure control valve, there are a number of factors that must be considered. A pressure control valve must be able to handle both the pressure and flow of the system being controlled or protected.

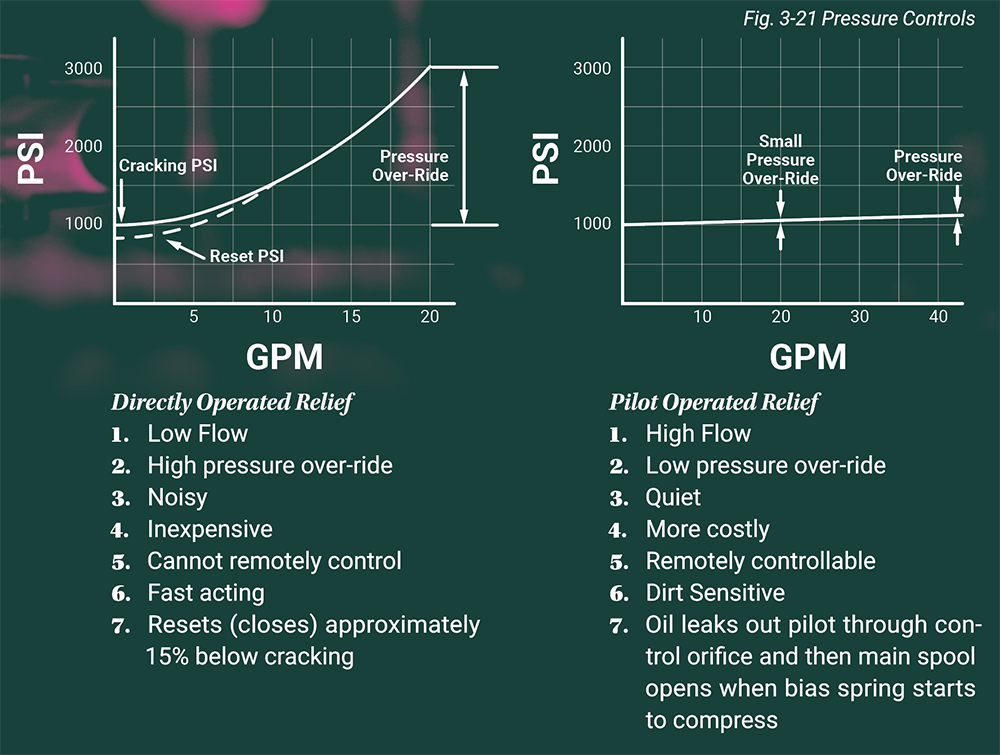

It is also important to understand the characteristics of the valve when setting the pressure. There can be a substantial difference between the cracking and full flow-pressure setting of the valve. A simple, directing acting relief is held closed by a spring pushing on a poppet or ball against a seat. When the pressure is great enough to act on the area of the poppet and lift it against the spring, the valve cracks open. However, the act of lifting the poppet compresses the spring and causes an increase in the pressure setting. As the flow past the poppet increases, there is a corresponding increase in pressure. A system whose relief is set at a cracking pressure may experience the stalling of the prime mover and/or greater than desired force at the actuator when full flow is being relieved.

A compound relief mitigates this effect by using a simple relief to vent the spring chamber of a main valve. The poppet in the main valve is held closed by a relatively light spring and by the system pressure that is felt through a small orifice in the poppet. When the pressure setting of the direct operating relief is met, the valve cracks open, venting the spring chamber of the main valve and allowing that poppet to open, relieving the system. The flow through the simple relief is relatively constant and so there is little difference between the cracking and full flow-pressure, up to the flow rating of the valve. The actual system pressure is an accumulation of the cracking pressure of the simple relief, the spring rating of the main valve, and the pressure drop through the effective orifice of the valve.

When the rated flow is passing through the valve, the poppet is fully open and the effective orifice is fixed at its maximum. Any increase in flow will result in an increase in system pressure known as pressure override.

The response time of a compound relief will be the combination of the opening of the simple relief and that of the main stage. Consequently, a compound relief will take longer to open than a simple relief. This is why a simple relief should be chosen when protecting against sudden pressure spikes.

Test Your Skills

1.The cracking pressure of a direct operating relief valve is:

a. The pressure at which the valve begins to open.

b. The highest pressure the valve can withstand.

c. Higher than the full flow-pressure.

d. The pressure at which the valve housing will split.

e. The same for all relief valves.