2018 Electronics Q&A

David Geiger, Moog

David Geiger, Moog

David is an engineering manager for Moog Inc. He works with hydraulic, electromechanical and hybrid actuation systems for industries, including machine automation and robotics. He earned his Bachelor’s in Physics and Engineering from the University of Waterloo.

Steve Zumbusch, Eaton

Steve Zumbusch, Eaton

Steve is Director of Technology Development for Eaton’s Hydraulics Business and has received a number of patents related to customer solutions. Steve earned his degree in Mechanical Engineering from the University of Minnesota and serves on several industry committees promoting fluid power research.

Edoardo Zilioli, Gefran

Edoardo Zilioli, Gefran

Edoardo started working in 1986 in the industrial market as an engineer with computer science specialization, creating firmware and software. In the years following the year 2000, he worked in the technical-commercial sector for several multinational companies, developing innovative products or developing business in new markets. He currently works as Corporate Marketing Manager for Sensors and Components for the Gefran Group, an Italian worldwide electronic products company.

How have electronics influenced the fluid power industry so far, and do you view this as a positive or negative development?

Geiger: There’s a heavy push on robotics and autonomous-type vehicles these days. Robotics have traditionally been inside a plant and closely controlled. Now robots are leaving the plants, working outside in difficult unstructured environments, and working alongside humans in areas such as agriculture, construction and mining.

At Moog this means that the machines need to be aware of their surroundings and to make intelligent decisions about what to do and how to do it in the most efficient way. These requirements drive a need for a whole array of perception sensors, such as cameras, radar and Lidar, as well as more traditional sensors. These sensors are used at the machine and axis levels to monitor performance. Then computing platforms are needed to process all this data and make decisions. Our work is going well beyond just closing the loop on a hydraulic system to also figuring out how to make these devices interact with their environment with reduced human input.

The opportunity is there to apply intelligent motion control, systems integration, and safety, in entirely new spaces.

Zumbusch: Electronics have changed the landscape tremendously, particularly over the last few years. This has allowed products with on-board intelligence, such as Eaton’s CMA valves, to provide huge improvements in load and motion control but also to take on additional functions. Now, built-in sensing allows machines to interpret upstream fluid signatures and communicate critical information, such as machine performance and prognostics for maintenance of large, complex systems.

Zilioli: The introduction of electronics in the fluid industry is definitely a positive development. Mechanics began to be influenced by electronics in the early 1990’s, and the term mechatronics, which finds a synergy between the worlds of mechanics and electronics, was created. In the last 15 years, fluid systems have been integrating more and more with electronic components, thus a new term, fluidotronics, has been created.

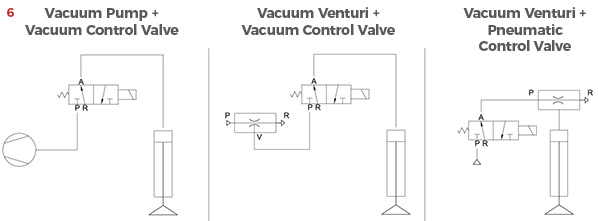

All this is to improve control and positioning by ensuring precise, timely, and especially, repeatable results. Think of a hydraulic circuit: the pressure transducers provide information about the pressure at the pump, and the more rapid the movements– with a ramp for fluid acceleration and one for deceleration– the more important is the accuracy of the components in question. Reading the pressure in real time in this case becomes crucial.

The position feedback of a hydraulic piston has also become essential information. The repeatability of movements must be guaranteed as the oil flow rate varies, depending on the temperature. Since the oil is a relatively incompressible fluid, it is easy to control the position of a piston of an hydraulic cylinder. Recent technology is now leading us to transfer the concept of controlled positioning to pneumatic cylinders. Once the target position is reached, the two areas of the pneumatic piston are pressurized to balance the forces, and only the high quality of today’s low-cost position and pressure sensors can provide the feedback necessary to maintain the locked position. This increases performance, and performance can be transformed into safety, short cycle times, and repetitive production quality.

What are the cost savings/benefits to utilizing more electronic controls in fluid power systems?

Geiger: Efficiency, safety and productivity.

More intelligent systems, using more electronic controls, enable the creation of systems that are more efficient, productive and safer. First, efficiency can be improved by monitoring and controlling the energy usage throughout the machine, as well as by optimizing the motion profiles of the vehicle movements. Efficiency is an ever-important topic as engine emission standards become stricter.

Next, productivity can be improved by automating some tasks that allow the human operator to focus on the more cognitively challenging parts of the job that humans excel at and machines do not. This increases the productivity, makes the job more satisfying for the operator and overcomes ergonomic problems that operators encounter from repetitive movements.

Finally, safety is critical when adding automation to a machine. Consider the safety of the operator and the safety of people who work around this machinery. An intelligent control system allows engineers to tie in a variety of sensors like Lidar, radar, cameras that augment the operator’s field of view. Safety critical systems are a key capability of Moog, and we are focused on how to incorporate new technology safely.

Zumbusch: One of the biggest benefits OEMs are seeing is improved productivity and management of how the machines do their work. With electrohydraulics (EH) you can now profile how a device is moved to even make it more gentle on things like bushings and structures.

As EH is used on machines, it now opens the opportunity to add electronic boxes like Eaton’s HFX controllers and create some really advanced functionality and coordination between multiple machine operations.

Another benefit is the time necessary to commission machines. Now, instead of swapping different spools and orifices in an attempt to get the performance they want, a customer can now spend a little time on a laptop and design the way they want the function to work and be done in 1/10th the time.

Zilioli: Recently I was in India, a country where there is continuous development of infrastructure and road, rail, and river communication networks. I met an old researcher from a leading manufacturer of excavator and pick & place vehicles, who, in recent years, had created his own company with his children. He told me that they were looking for a solution that would allow dealers to increase safety. Excavators were used by personnel that did not have much professional training. But did the dealers only want to prevent inexperienced operators from doing harm to themselves or others? No, they were also looking for a way to control and stop the vehicle when the operator was using it improperly. For example, excavators were not only used to transfer or remove soil, but also to split and crush rocks, and this reduced the life of the bucket and all mechanical and hydraulic components of the excavator.

This was the first time that not only did we want to safeguard human life by, for example, avoiding the vehicle tipping over, but we also wanted to take care of the proper use of machinery. My suggestion was in that case to detect if pressure peaks were too frequent and too close together. If they were, it meant that the excavator was being used in an extreme manner, like a pneumatic hammer.

This real-life story is to show that in addition to the well-known benefits of using electronic controls, man/machine safety is becoming increasingly necessary and urgent. Within 10 years, robots or cobots (instruments that interact with employees within the company) will replace human beings in fatiguing, repetitive work; the farmer will no longer have to spend his time on the tractor to plough or treat the agricultural fields. There will be autonomous vehicles, and the first of these are already operational, tractors that no longer have the operator’s cabin, a steering wheel, or an accelerator and can move without the need for constant human control.

(For an example of an autonomous vehicle, see https://youtu.be/fDWrJXJId2s?t=114)

What should fluid power professionals and companies do to prepare for and embrace this integration?

Geiger: Applications are becoming more multi-disciplinary systems problems, not just hydraulic control. So we all need to educate ourselves about the new sensors and computing platforms that can be used to build better and safer machines. For example, Moog is looking at perception systems and how to integrate these with motion control systems. Understanding how this integration impacts safety is a key piece of this problem that must be understood and thought about from the earliest stage of development. As workers encounter collaborative robots, safety requirements take on a completely new level of importance. Moog’s aerospace flight control heritage has equipped us with an understanding of the various levels of redundancy necessary for electronic systems that interact with humans.

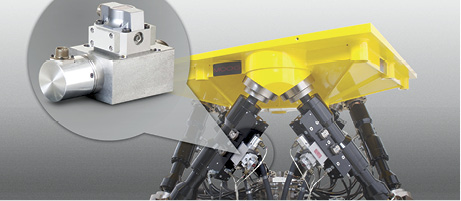

Another capability to understand and embrace is additive manufacturing. As hydraulically powered robots enter uneven, open terrains, they have to be lightweight, unlike the large, heavy robots that move short distances inside a factory. Additive manufacturing is one way to keep the weight down in developing the kind of robots that will have to keep pace with and work alongside humans.

Zumbusch: One of the biggest things an OEM can do is look at the opportunity from a system perspective and consider how the entire circuit could be improved with the move to electrohydraulics (EH). There are a lot of great valve choices out there that offer a lot of benefits for the taking.

Taking on EH has been getting easier and easier too, as suppliers make the interfaces simpler to work with and more intuitive.

Zilioli: Support the development of this integration, and thus create fluidotronics. Large manufacturers of hydraulic and pneumatic components have been doing this for a couple of decades, and this is one reason they maintain their leadership. Companies that now adopt these new solutions will need a very steep learning curve. In the next 10 years, communication between the various electronic components will become increasingly digital; therefore, companies must invest in the training of personnel who will then design, install and maintain the new systems or plants that will increase efficiency by communicating with each other, ideally starting from the purchase order of materials, to the storage, processing and shipping of the finished materials.

How much do you see the Internet of Things (IOT) impacting designs and requirements related to fluid power systems?

Geiger: One word: Huge. All of the sensors that we’re loading onto equipment will collect a vast amount of data, and people will want this information at the ready to optimize designs. As a vehicle is moving through an environment, there is endless opportunity to collect and analyze information from the multitude of sensors that now exist. Collecting and analyzing this data will make designers, their vehicles, and end users more productive and valuable.

Zumbusch: IoT is having a huge impact on the industry and machine designs. Features that used to be decided when the machine was purchased can now be turned on once customers decide to add a new value function to their machine. Machines can now communicate with one another to improve the overall worksite by coordinating machine functions to reduce waste and idle time spent waiting for another machine to do its function.

Zilioli: IOT is a system that will once again disrupt the B2B and B2C market, and the first examples are already highlighting the power of the technology. The Internet of Things will allow us to simply inventory objects and know, for example, where the articles are located in the various construction sites or in which of the company’s warehouses, or to know from whom, how many, and how the components have been used. All this information, introduced with the advent of the IOT, will allow us to carry out point analysis and design the new products precisely for the purpose without overflow or expensive frills.