At the Crossroads: Smart Sensor Connectivity

By Dennis B. Carstensen, Senior Business Development & Portfolio Manager, Danfoss

By Dennis B. Carstensen, Senior Business Development & Portfolio Manager, Danfoss

Global industries are at a crossroads. Urbanization and globalization are driving new economic, environmental, and social demands for greater efficiency, safety, and optimization – and so OEMs, wholesalers, and installers must determine how to confidently navigate Industry 4.0 and digitalization.

Fortunately, at the heart of the paradigm shift from analog industrial processes to digital products and solutions are smart sensors. Across primary industries around the world, smart sensors are the central driving force behind implementing connectivity and are empowering businesses to achieve ambitious goals for optimization.

The Industrial Internet of Things (IIoT) has made a smooth transition from analog sensors to digital smart sensors possible. No longer limited to simply passing an electrical-measurement signal along, smart sensors collect, convert, and process data – and offer machine-to-machine communication. This enables predictive maintenance, improved productivity, and flexible and responsive manufacturing. In other words, businesses experience entire value-chain optimization, achieving more with less in the ultra-competitive Industry 4.0 marketplace.

No industry is left untouched: from mobile hydraulics to water management, and from marine to wind power, smart sensor connectivity allows industries to use resources in smarter ways. And that means businesses can maintain a competitive edge and respond to megatrends such as smart cities and electrification.

This article presents an overview of the smart sensor connectivity of tomorrow, an exploration of the driving forces behind smart sensor technology and the reasons why it is a future-proof solution.

The challenges and payoffs of digitalization

With every great industrial innovation comes the challenge of implementation. In the case of Industry 4.0, technical integration, organizational transformation, data security, and future viability all play a role in assessing how to integrate IIoT technologies into business models.

However, smart sensors are the framework for taking full advantage of IIoT, and major payoffs await on the other side of implementation. Data and information that is captured, processed, evaluated, and communicated by smart sensors mean organizations can take action on optimizing industrial processes both vertically and horizontally.

No longer limited to process control, the ability to purposefully analyze and process manufacturing data through smart sensors fosters the transparency of value creation. This new way of activating data opens the door to new business opportunities such as predictive maintenance, flexible manufacturing processes, and improved productivity.1

Ultimately, however, the main business challenge is not about the adoption of Industry 4.0 technologies; it is the fact that primary industries must do more with less to remain competitive in the digitalized global marketplace. And smart sensor technology is one of the gateways to taking full advantage of IIoT and optimizing your business model.

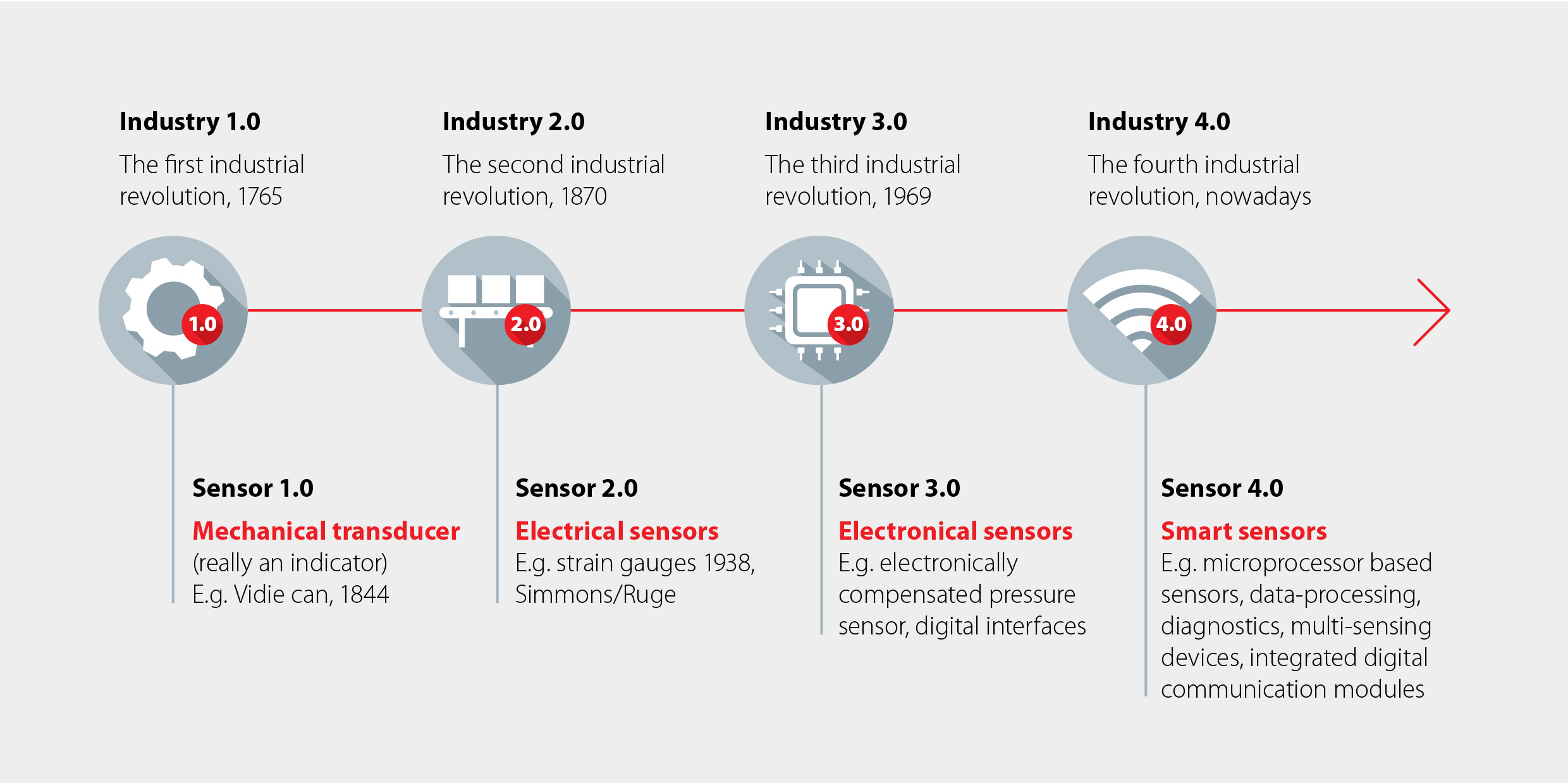

The transformation from Industry 3.0 to Industry 4.0

The role of industrial controls continues to evolve at a faster pace than ever before. That means every sensor on the plant floor, production floor, or the application site is going to be smart, connected, and IIoT-ready.

In order to anticipate industrial controls of the future, it is important to understand the controls of today and why they are needed. Industry 3.0 – or the Digital Revolution – marked the shift from manual pushbuttons and relays to the first programmable logic controllers (PLCs) and digital human-machine interface (HMIs). PLCs made it possible to reconfigure an HMI screen when mechanical devices failed, providing both cost- and time-saving benefits.

Industrial controls served a basic but pivotal role: the ability to turn electrical devices on and off and control operational speed. However, data collection and analysis were not on the Industry 3.0 agenda: the primary focus was to establish reliable process control, so data was collected manually with chart recorders and external hard drives.

As PLCs, HMIs, software, and embedded controllers became mainstream, the possibility of starting to automatically collect data instead of using manual processes became a reality – marking the dawn of Industry 4.0.

Industry 4.0 enables manufacturers to harness digitized, connected, smart, decentralized value chains through the integration of IT technologies. In other words, it allows businesses to capture increased efficiency while preparing for the next wave of industrial innovation.

In the face of market volatility and complexity, smart sensor technology delivers the automation, safety, and optimization we have been accustomed to through traditional PLCs and gateways, but is empowered by networks, machine-to-machine communication, and machine learning.

What defines smart sensor technology

Smart sensors are the backbone of Industry 4.0 and its success. As a central driving force for innovation, smart sensor technology makes industrial processes more efficient but also has broader economic, environmental, and social benefits. From megatrends such as smart cities to critical ecological impact such as reduced energy consumption, smart sensors are driving the world forward.

Responsible for enabling the automated and more accurate collection of environmental data, smart sensors are crucial elements in IIoT applications and data ecosystems.

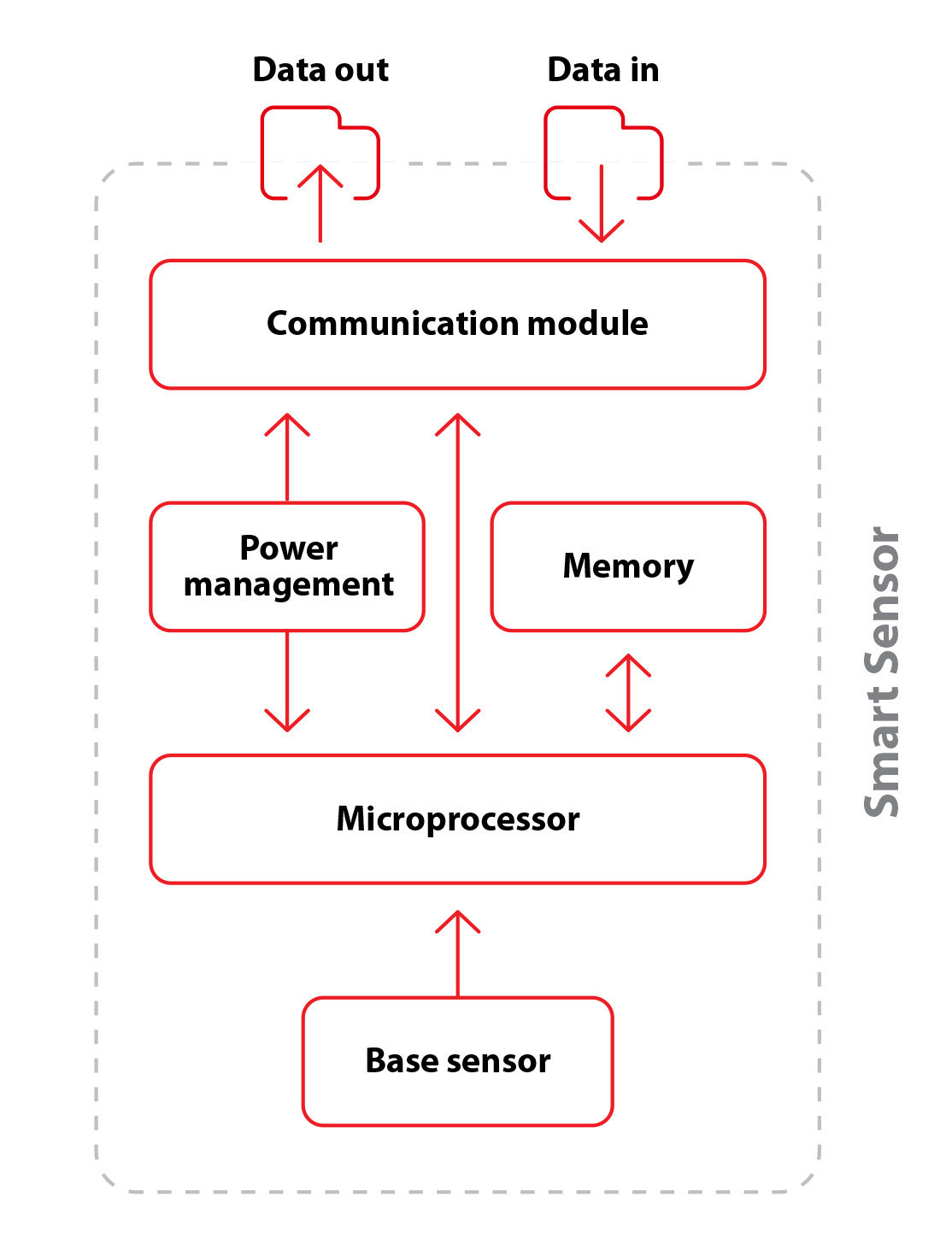

A smart sensor is a device that takes input from the physical environment and uses built-in computer

resources to perform predefined functions based on specific input. It then processes data before passing it on. If a sensor simply sends an electrical measurement signal forward for remote data processing without additional information, it is not considered a smart sensor.

At a minimum, a smart sensor comprises a sensor element, a microprocessor, and a communication technology. Computer resources, typically provided by low-power microprocessors, must be integrated with the physical design.

A smart sensor also incorporates software-defined elements that provide functions such as data conversion, digital processing, and communication to external devices. In more advanced cases, a smart sensor can support various sensing technologies, handling and delivering multiple measurement values.

Used for monitoring and control mechanisms in a wide variety of applications, smart sensors are used in water management, mobile hydraulic, marine and offshore, wind power, and HVAC applications, to name a few.

Drivers of smart sensor technology

Access actionable data and information. A distinguishing factor of smart sensors is their ability to provide actionable data and information resulting in benefits such as predictive maintenance and troubleshooting.

With an embedded microcontroller solution, smart sensors have the intelligence to take care of the signal conditioning and calibration of the sensor signal itself. They also handle and store information inside the sensor. By storing data such as a part number, supplier information, target-application information, production date, and the software firmware version, it is possible to improve application complexity and the quality monitoring system.

Smart sensors also provide automatic self-diagnostics that can reduce critical downtime by passing on diagnostic information for improved root-cause analysis. For example, maximum measurements recorded over the sensor’s lifetime, such as over-pressure and max. temperature, are valuable when investigating an application quality issue or field-return case.

Simplify the wire harness at the edge/application. Each analog sensor in an application control loop has to be individually wired to the controller interface, often leading to complex and expensive cable-harness solutions that at the same time make troubleshooting difficult.

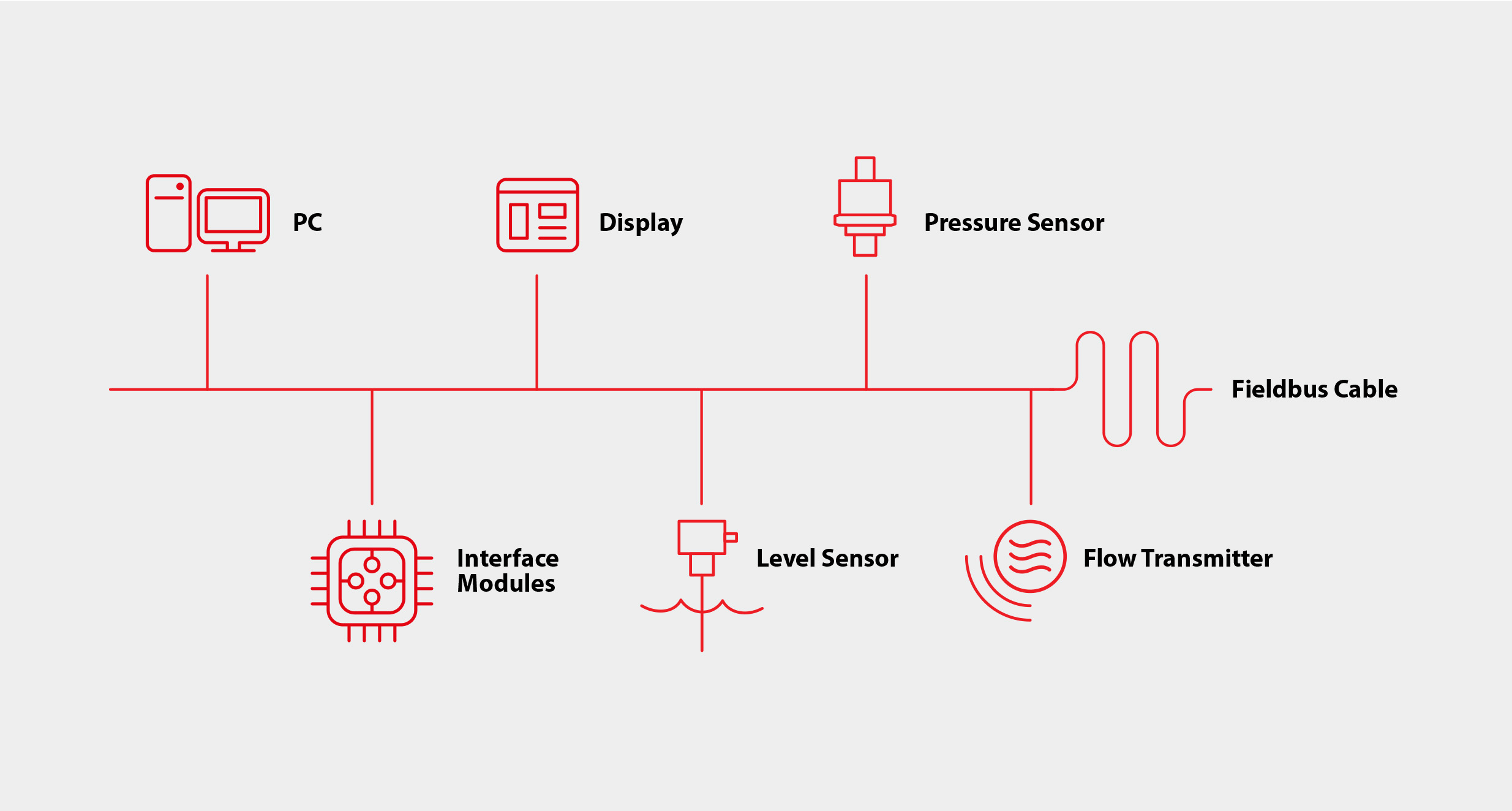

A smart sensor communicating directly on a digital fieldbus is daisy-chained to the fieldbus cable rather than running individually to the controller. This significantly reduces the cable-harness cost and complexity and creates a simplified environment for troubleshooting at the application site.

Optimized input/output hardware architecture. The digitalization of customer environments and applications is driving the demand for more sensors to control, monitor, and improve system performance and efficiency.

However, this often poses a challenge to the physical limitations of controllers when multiple sensors need to be added to the hardware architecture. Because controllers are often tailored – and therefore limited – to specific application needs, the demand for more sensors hits a bottleneck on the input/output (I/O) side of hardware architecture.

Opting to change some or all analog sensors to digital fieldbus sensors can solve the controller I/O challenge. Most controllers have fieldbus capability used for higher-level system communication; this simplifies the process of expanding the communication protocol down to the sensor and actuator level.

Unique sensor identification. Smart sensors provide interesting and relevant information to the controller through digital communication. Each sensor in the system has a unique identification number that can be related to specific application characteristics. This unique identification number addresses the sensor in a communication chain, which means controller algorithms can use this information to evaluate whether

it is connected to the correct sensor and hence is receiving valid data. Thus, it automatically detects if an incorrect sensor has been installed or two sensors have been mixed up.

Configuration via communication. A duplex or semiduplex communication solution enables new programmable features. Communication from the controller to the sensor can be used to change, configure, or fine-tune specific settings and parameters stored in the sensor.

This level of programmability makes it possible to achieve specific optimization goals such as improved measurement resolution and accuracy in the narrow measurement range of an application’s predefined operating mode.

Moreover, smart sensor configuration significantly reduces complexity. For example, a single sensor can be programmed to multiple measuring ranges depending on the installation point and application information that could be received by the controller. This reduces the amount of sensor part numbers in the customer’s supply chain, simplifying day-to-day application management.

The power of remote technical support

A key factor in realizing the full potential of smart sensor technology is how it can be linked to remote technical support.

Digital communication capabilities allow application and product specialists to access sensor-setting files. A specific sensor configuration can be uploaded and downloaded through the communication protocol or an external sensor- communication tool. Technicians can remotely modify sensor settings to new application demands and requirements by evaluating a downloaded sensor setting file from the application field site, factory, or laboratory.

This enables a remote simulation and evaluation of sensor behavior and diagnostics by technical experts, which can be beneficial when configuring or fine-tuning sensors in the design-in phase. A modified file can then be sent back to the application where it can be uploaded to the sensor, resulting in the new configuration of the sensor taking over immediately.

Involving remote technical experts can likewise be helpful when evaluating diagnostics from the sensor in a critical root-cause analysis situation to minimize costly application downtime.

The influence of smart sensors on machine learning and AI

A growing field of interest in a wide range of application control and monitoring systems is advanced analytics for machine learning and artificial intelligence (AI) algorithms.

Moving forward, advanced analytics will significantly increase machine intelligence, enabling the smart solutions of the future. Predictive maintenance, machine-health monitoring algorithms, and new ways of increasing system performance will be key. But the analytics perform only when fed with relevant data supplied by smart sensors.

Machine learning and AI algorithms can consume and react to smart sensor data such as the sensor’s serial number, model number, installation date, calibration history, and self-diagnostic information, as well as application-specific data such as who installed the sensor, when it was last powered up, and internal-measurement data.

Turning smart sensor data into actionable information is critical to the evolution of industrial businesses. Smart sensors make it possible to utilize connectivity and keep pace with innovation.

For more information, visit www.danfoss.com/en/products/sen/sensors-and-transmitters/.

1. Arnold, C., Kiel, D., Mueller, J., and Voigt, K. 2017. “Sustainable Industrial Value Creation: Benefits and Challenges of Industry 4.0.” Friedrich-Alexander University Erlangen-Nürnberg.