Bosch Rexroth and Tulip Announce a Strategic Alliance to Launch Smart Workstation

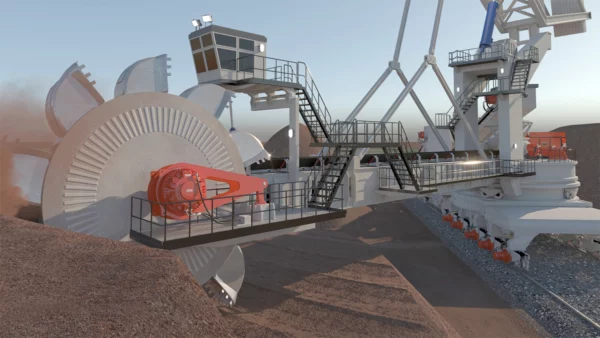

Bosch Rexroth and Tulip collaborate to launch a Smart Workstation, a joint customer-focused product that combines Bosch’s manual production system with Tulip’s Manufacturing App Platform to create a powerful Industry 4.0 workstation. The Smart Workstation leverages IoT-enabled manufacturing apps to transform traditional bench-top operations, increase operator productivity, improve quality, and collect and visualize real-time manufacturing data. The Smart Workstation is the result of a strategic alliance between Tulip and Bosch, who are joining forces after successfully collaborating at multiple customer sites. The workstation is built to order and comes ready to use.

Bosch Rexroth and Tulip collaborate to launch a Smart Workstation, a joint customer-focused product that combines Bosch’s manual production system with Tulip’s Manufacturing App Platform to create a powerful Industry 4.0 workstation. The Smart Workstation leverages IoT-enabled manufacturing apps to transform traditional bench-top operations, increase operator productivity, improve quality, and collect and visualize real-time manufacturing data. The Smart Workstation is the result of a strategic alliance between Tulip and Bosch, who are joining forces after successfully collaborating at multiple customer sites. The workstation is built to order and comes ready to use.

The Smart Workstation integrates Bosch’s IoT devices such as the Bosch XDK110, an environmental sensor; the Bosch Rexroth ID200, an RFID system; and the Bosch Rexroth Nexo, a cordless nutrunner have been added to the growing supported Device Ecosystem, which makes them ready to use with Tulip. It also comes retrofitted with a Tulip I/O Gateway, which connects all devices and machines to Tulip’s Manufacturing App Platform, a Tulip Light Kit, an easy-to-program pick-to-light solution, as well as a number of other industrial sensors to get manufacturers started with IoT-enabled manufacturing apps.

Natan Linder, CEO at Tulip, added, “We’re proud of this alliance with Bosch Rexroth. This is the first time manufacturers are able to design their digital experience online and get a fully functional workstation delivered on their shop floor, ready to use out of the box. This will completely redefine the manufacturing workbench.”