CCEFP Fluid Power Research Webinar Series

“Co-Simulation: The Road to a More Precise Model”

The CCEFP webinar series continued with a presentation on May 24 with Celine Cabana, technical account manager at FD-GROUPS America, Inc. The topic was “Co-Simulation: The Road to a More Precise Model,” which detailed a dynamic simulation study of the complete hydraulic system for the MPG (Multi-Purpose Gantry) being operated in the London Subway. The purpose was to understand how to close the gap that exists between the virtual prototype and the actual machine. While the machine is in operation, torsion in the structure affects the hydraulic system’s performance. In integrating the deformation of the static part with the dynamics of the vehicle, the engineering entity of FLUIDESIGN Group performed a study on a complete new articulated boom lift design.

The intention of the numerical simulation, performed in conjunction with Haulotte Group, was to validate the mechanical structure and the hydraulic sizing of the new articulating boom lift kinematics. The mechanical structure and hydraulic actuation modeling allowed the researchers to understand the interaction between the two physics that govern the boom behavior. Vibratory phenomena related to the bodies’ flexibility and the actuators’ dynamics were studied via a co-simulation method with Virtual Lab Motion and AMESim software.

From inception of the project, the risks were substantial, mainly on the backward stability of the machine. The chosen methodology was to perform a co-simulation. The 1D dynamic simulation confirmed the hydraulic system sizing, validated component choice, and verified hydraulics and mechanical structure stability, while the 3D mechanical model confirmed the dynamic stability, calculated the loads in the connections, and validated the effects of the controls done in the dynamic simulation on the behaviors of the machine’s systems.

In each section of the co-simulation, the models were optimized in order to perform as required. The coupling of the models was then achieved, and the researchers were able to verify the operation and the controls. They tested the virtual prototype with the recommended profile. They noticed an imbalance in the pressure at the moment the boom was going down, with an amplifying effect as it was progressing. They evaluated different solutions, both in the component sizing and on the operation controls. They could then manage the controls before the material prototype was built.

The first trials of the actual prototype were conclusive. Not only did the researchers achieve a gain of time in the fine-tuning of the machine, but they were also able to reduce the design time significantly. The multitude of benefits by using co-simulation allowed them to foresee the future perspectives of using this type of methodology. Co-simulation is a powerful tool to build numerical models closer and closer to reality.

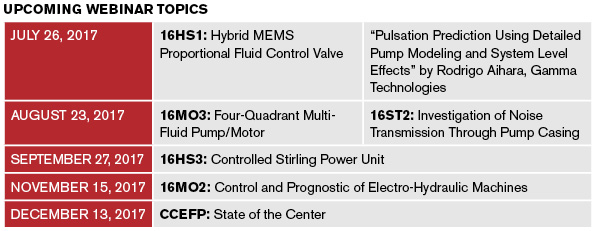

About the CCEFP Webinar Series

The series is a monthly webcast with research, workforce, and special topic presentations hosted by the CCEFP and sponsored by NFPA. Listeners learn more about fluid power research projects at the CCEFP and how they benefit the fluid power industry. Registration is required to attend these free webinars, and interested NFPA members can sign up at www.ccefp.org.