Compressed Air Maintenance

By Ron Marshall, Marshall Compressed Air Consulting

Like any industrial equipment, the air compressors, dryers and associated components on your compressed air system need occasional attention. It is very tempting to stay out of that dark, hot and dirty compressed air room, especially if the air compressor is running trouble-free, but maintain the system you must. Maintenance intervals can be stretched for a while, but it usually comes back to haunt you in the end, like the old Fram oil filter commercial says, “Pay me now or pay me later.”

If you have compressors that run continuously, you need to be especially diligent. It is often quite easy to relate the oil changes of your compressor lubricant to the oil changes for your own personal vehicle, thinking infrequent oil changes are acceptable, but for a compressor that runs all the time, it is important to ensure the lubricant stays in good condition, requiring timely changes to the compressor oil, often more frequent than you would expect.

Air compressor lubricant for oil-injected screw compressors is fairly expensive, but for a few good reasons. The duty inside a screw compressor is not normal. The lubricant reduces friction in the internal parts, like all lubricants, but it is also in direct contact with compressed air at high pressure, exposing it to the negative effects of oxygen. The oil is also used as a coolant, carrying away the heat of compression. It captures particles of dirt that are sucked into the compressor and get past the inlet filter, reducing its quality. And it traps the condensed moisture that forms when air is compressing, contaminating it further.

Compressor lubricants have additives to prevent oxidization and to extend its life in these harsh conditions, but these measures only last for so long. Once the lubricant reaches the end of its lifetime, if pushed beyond normal, damaging deposits will start to form inside the compressor that will clog up bearing and cooling surfaces with varnish. Its only a matter of time before overheating, bearing wear, and oil carryover cause major rebuild costs, or worse, the total failure of the compressor.

Some tips about compressor maintenance:

- Compressor lubricant failure is a major cause of problems with air compressors. Do not skimp on regular and timely oil changes with high-quality lubricant.

- Compressor lubricant and inlet filters need regular replacement. Think twice about buying inexpensive replacement filters from third parties. Always ensure any filter meets the required extreme duty for air compressors.

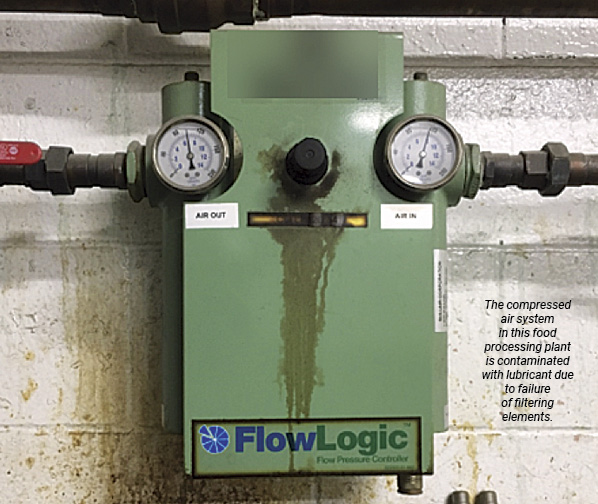

- For screw compressors, the condition of the oil separator is quite important. Failure of this item can cause high quantities of compressor lubricant to pass downstream so regular maintenance is required, as well as timely replacement.

- Compressor coolers must be kept clean, and ambient conditions reduced to a cool environment as much as possible. The major output of an air compressor is heat, overheating the compressor lubricant greatly reduces the life of the lubricant and causes premature compressor failures.

- Compressor main and fan motors need to be kept clear of debris as clogging of internal cooling air passages will lead to early failure.

- Keep compressed air filters and water drains well-maintained so contaminants do not pass downstream.