Controlling pressure is controlling temperature for steam applications

SPONSORED CONTENT

Many applications for controlling steam use a valve with a temperature sensor downstream and a customized PID program. When the valve is at set point, the sensor tells it to stop, but by that time the valve has overshot. Then coming back down to set point, it undershoots. This “dithering” happens until it stabilizes and even then the accuracy can be questionable.

Rather than using a valve, a regulator offers faster, more accurate temperature control because it has internal sensing and can “see” the pressure needed. A valve is meant to throttle flow, whereas a regulator is designed to control pressure. Since pressure and temperature have a direct correlation, a controller sets the pressure equal to the desired steam temperature and that’s it: Steam regulators go straight to the desired temperature and hold it steady – no dithering or over/undershooting and no PID loop required.

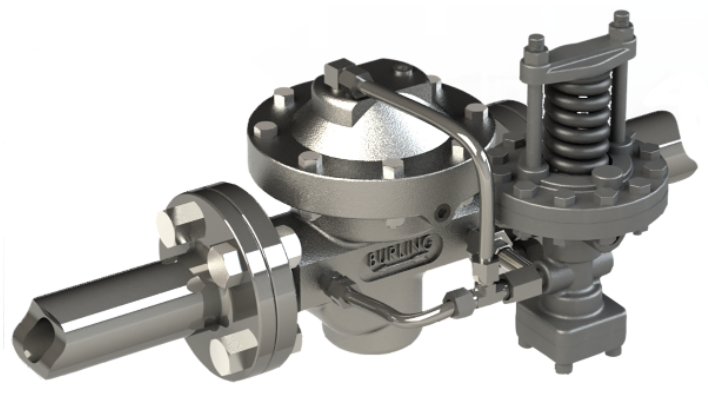

Burling Valve offers regulators for steam and other applications that require pressure control for most gases and fluids. Featuring top-entry inline maintenance, Burling Valve products save time and lower repair costs.

Fast delivery • Competitive pricing • Numerous wetted and body materials • Large CVs

Burling Valve | A Proportion-Air Brand

McCordsville, Indiana

888-200-9564

sales@burlingvalves.com

BurlingValve.com