Drive-Through: Hydraulic AWD Takes It on the Road

By Paola Ipsa, AddiDrive Program Marketing Manager, Poclain Hydraulics —

Maximizing productivity and safety while minimizing CO2 emissions is a top priority for many people in many industries. For companies that use trucks, the challenges they face include maximizing payload, uptime, and material lifetime while minimizing fuel consumption. Add to these challenges recent supply chain constraints all over the U.S. and diminishing spare-part inventories. With all-wheel-drive trucks, finding the right compromise for the job and route is paramount to ensuring a truck gets the job done effectively.

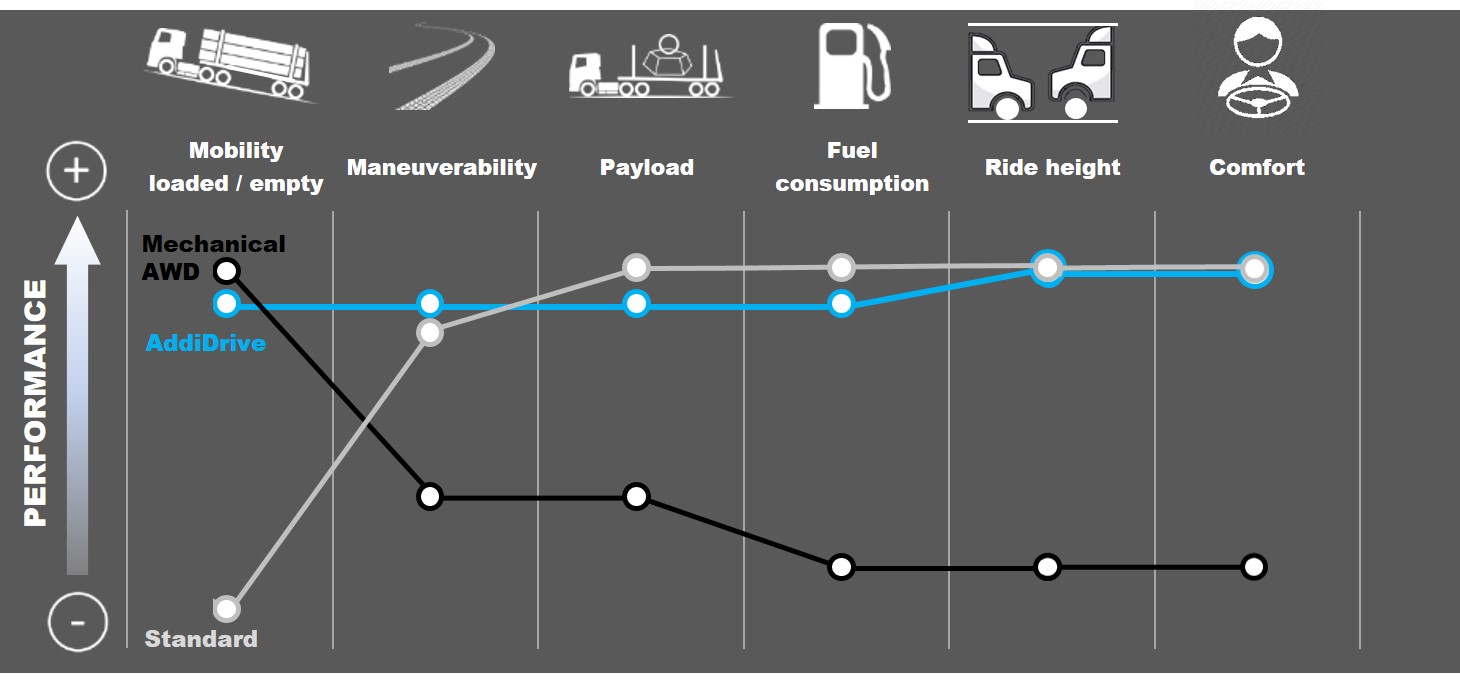

The most popular trucks on the market today are those for on-road applications such as long-haul trucking. Those trucks are optimized for driving on the road but not for rough terrains, as they are not supposed to drive off-road. On the other hand, mechanical AWD versions are perfect off-road but offer limited on-road performance. Having only these two alternatives presents a problem for vocational application truck users who spend nearly all of their time on-road and only a small amount of it off-road. They are based either on a standard long-haul truck that can get stuck in off-road conditions, or, if based on a mechanical AWD transmission, they limit their on-road performance.

Mechanical AWD is a solution for high mobility needs and low distance driving. It is optimal for trucks working almost exclusively off-road. To avoid risk to mobility in this type of application, a common solution is to acquire a mechanical AWD truck that copes with difficult situations with or without load-maximizing uptime. However, mechanical AWD has constraints, such as a reduced turning radius, which dramatically limits maneuverability. Furthermore, AWD necessitates increased ride height, creating constraints when driving on-road. This is especially limiting when it comes to height restrictions on bridges and tunnels, and even more so for utility trucks with over-cab lifts or cranes already at the limit of height regulations. Moreover, mechanical AWD reduces the payload and increases fuel consumption, which makes it not suitable for driving on-road most of time. This makes AWD inappropriate for trucks in applications such as fire and rescue, construction, towing and recovery, or other specialized hauling applications.

A compromise for these types of applications, the best of both worlds, so to speak, is an on-demand AWD hydraulic system that has the capability of a standard truck in off-road situations but maintains its on-road performance. This type of solution delivers optimal mobility in difficult driving conditions, such as mud, snow, slope, or sand, improving maneuverability by keeping a standard turning radius and improving the grip on unstable terrains or in low-adherence situations.

With Poclain Hydraulics’ on-demand hydraulic AWD system AddiDrive, there is no need for a cab height increase; the axle fits perfectly with standard chassis integration, which means the same ride height as a standard truck. Having traction in the front wheels does not affect the installation of auxiliaries or truck-height compliance for road regulations. The system has minimal impact on payload and fuel consumption. A truck with the AddiDrive system can carry 600 pounds less payload than a standard truck and 1,400 pounds more than a standard truck with AWD. Fuel consumption with the AddiDrive system increases by only 0,5-1% while a mechanical AWD increases fuel consumption by 10-15%. The system increases tire lifetime by avoiding excess slippage. It also lowers total cost of ownership because of reductions in downtime, maintenance, fuel consumption, and tire usage. It boosts productivity by maximizing the daily payload and offering better comfort and safety for the driver.

From a driver’s perspective, keeping the same cabin height as a standard truck improves comfort and optimizes the driver’s visibility and ergonomic accessibility. The system also reduces stress and fatigue on the driver and provides peace of mind that he or she will meet their mileage goals. Additionally, on-demand hydraulic AWD, through increased mobility without added height, reduces the planning required of fleet managers and drivers by optimizing routes and thus driving hours. Even when drivers encounter harsh weather conditions or irregular terrain such as fields, forests, or construction sites, they will not get stuck or lose valuable time.

From a driver’s perspective, keeping the same cabin height as a standard truck improves comfort and optimizes the driver’s visibility and ergonomic accessibility. The system also reduces stress and fatigue on the driver and provides peace of mind that he or she will meet their mileage goals. Additionally, on-demand hydraulic AWD, through increased mobility without added height, reduces the planning required of fleet managers and drivers by optimizing routes and thus driving hours. Even when drivers encounter harsh weather conditions or irregular terrain such as fields, forests, or construction sites, they will not get stuck or lose valuable time.

Besides advantages to end users, an on-demand hydraulic AWD system has a positive impact on the environment. Reduced slippage increases tire lifetime, which reduces waste and fuel consumption, thus limiting emissions. It also means there may be no need to pave access to the work site. Additionally, the system reduces the risk of cash spent for towing a stuck standard truck, which is beneficial to fleet managers, drivers, and the environment. By keeping the same fifth-wheel height as a standard truck, the manager can unify his fleet of trailers.

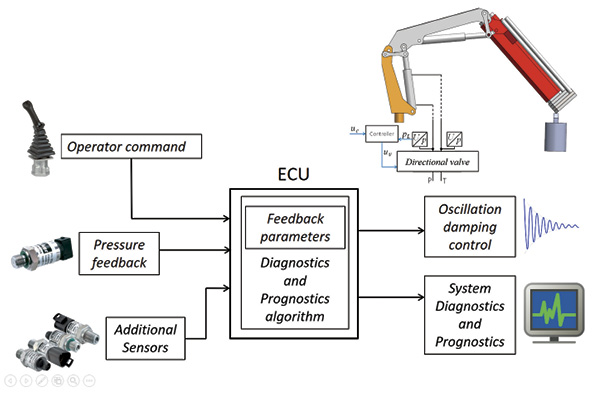

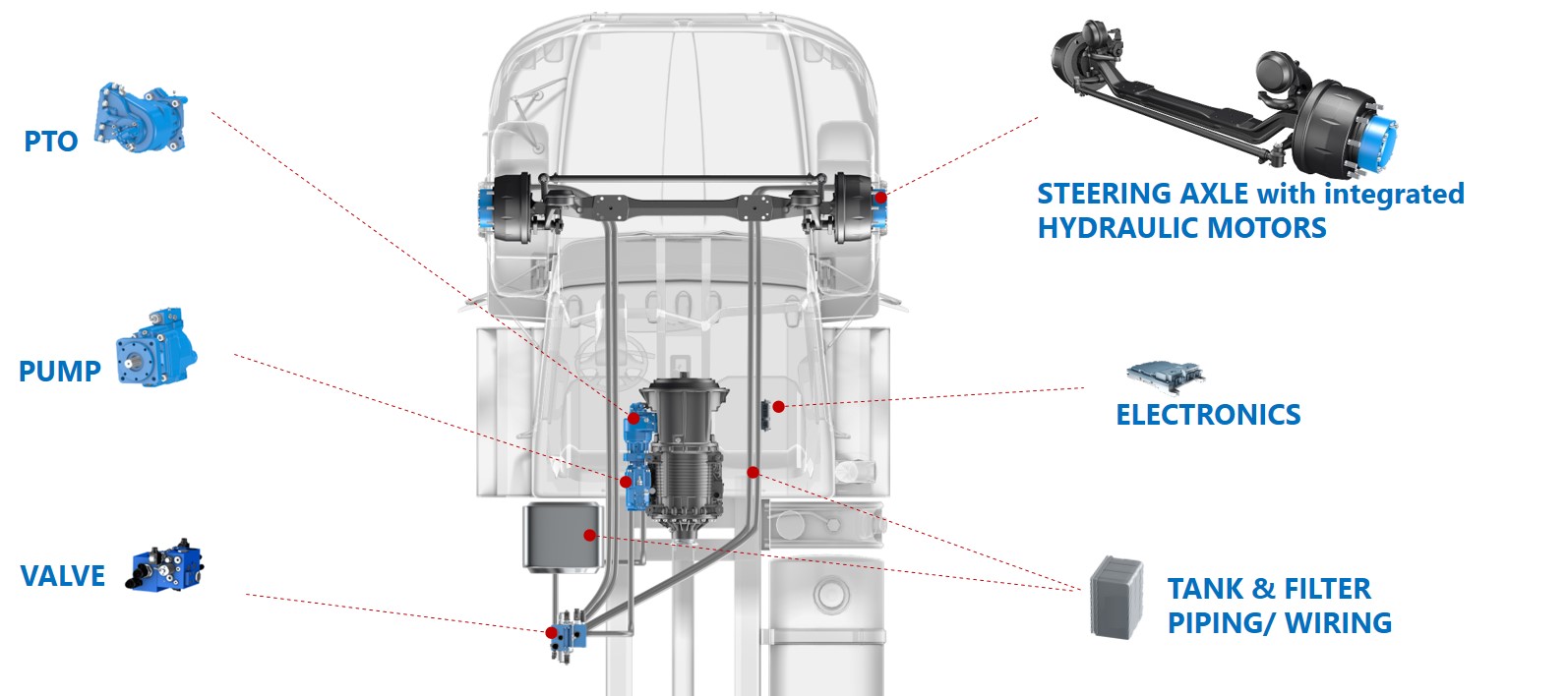

On-demand hydraulic AWD system architecture is relatively simple. The new AddiDrive open loop system optimized for U.S. trucks consists of a load-sensing-type pump, a valve, an electronic control unit, and two motors assembled onto an axle that is fitted inside the truck’s wheels. Besides these components, the system requires a hydraulic tank, a filtration system, and pipes and wiring to ensure connections.

For system integration, the system must be fully adapted to U.S. standards for U.S. trucks. In the new AddiDrive open loop system, the motors are tailored to fit U.S. standard rims, while the axle covers a full range of load capacity. The pump is compact and the tank is easy to integrate without taking up space needed for other components. Thus the system fits trucks from class 6 up to class 8. Moreover, the system is compatible with U.S. truck power take-offs. Allowing assembly of the pump directly onto a transmission PTO makes for a compact and optimized integration that does not interfere with work done by the body’s builder and upfitters, making it fully compatible with their tools. At speeds up to

12 mph, where increased traction is often needed, the system is able to provide 5,000 lbf tractive effort at 5,100 psi (351 bar).

When the system is activated, the pump, powered by the transmission PTO, generates and provides flow to the valve block, which ensures safety and manages the motors’ activation. The valve block splits the flow between two motors, providing traction. The electronic control manages communication and pilots the system.

Contrary to a mechanical axle, on-demand hydraulic AWD delivers torque only at the required level and only when needed. The driver maneuvers a switch on the dashboard, activating the system and allowing it to engage and disengage. In AddiDrive systems, engagement and disengagement can be done on the fly, while the vehicle is moving.

On-demand hydraulic AWD has two modes: traction mode, in which the hydraulic-powered axle delivers torque, and freewheeling mode, in which the two hydraulic motors are disengaged.

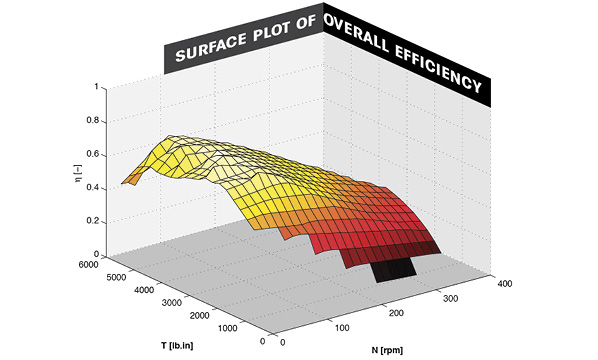

In traction mode, the AddiDrive system can drive the truck up to 12 mph, after which it automatically disengages. Depending on the resistance created by the machine to move, maximum pressure may be applied in the hydraulic motors to provide around 5,000 lbf additional tractive effort. Maximum torque can be applied from 0 mph; afterward it will be adapted at higher speed usage, never exceeding maximum power limitation. Maximum tractive effort is optimized depending on the front-axle load and low-adherence conditions typically encountered in difficult situations. While the traction mode is active, the pump displacement is controlled to ensure speed synchronization between the front and rear wheels. Additionally, the driver can adjust the pump displacement to the required level of system pressure.

When the system is disengaged, the pump returns to the neutral position and the two motors switch to freewheeling mode, reducing system drag losses to a minimum.

Generally, integration for this type of system occurs at the OEM level. It offers OEMs an opportunity to differentiate their product. OEMs can deliver more versatile truck models with efficient performance both

on- and off-road without the constraints of a mechanical AWD. The front axle is fully equipped with a plug-and-play solution compatible with the chassis installed on the normal axle; only the pipes need to be attached. This type of plug-and-play system offers fast integration at the OEM level requiring low resource.

When specifying a truck AWD solution, the work and application needs to be carefully examined. Whether a work truck is destined for full or partial off-road driving needs to be analyzed carefully to optimize the total cost of ownership and deliver a right-sized solution for each application. Having a choice between full-time and on-demand hydraulic solutions allows OEMs and fleets to differentiate themselves further in the market.