More Than Hot Air: Applying Pneumatic Energy to Automotive Applications

For motorists and vehicle operators concerned with efficiency and reducing their environmental impact, hybrids are an attractive solution. Any vehicle with two or more distinct power sources qualifies as a hybrid, the most popular of which are electric and hydraulic systems. Both technologies are a proven means of improving vehicle efficiency and fuel economy through energy capture, storage, and release.

Energy capture is most commonly done through regenerative braking – harvesting the energy produced when a vehicle applies its brakes. This is the main way that the Toyota Prius and other popular hybrid electric vehicles generate supplemental power. It’s also true of hydraulic hybrids, except they store their energy in pressurized fluid rather than electric batteries.

Each system has its advantages, disadvantages, and preferred applications. For heavier vehicles like trucks and buses, hydraulic hybrids are often more effective at capturing and reusing energy. Electric hybrids predominate in smaller vehicles, which do not need as much power to maintain speed as their heavier counterparts do. Hydraulic systems are also popular in heavy-vehicle applications where the cost and weight of effective batteries is prohibitive.

Despite their clean energy and environmental benefits, both systems present an “e-waste” risk; old batteries can be harmful if not properly disposed of, and the spilling of hydraulic fluid is a real environmental concern. Both systems also ultimately add drag to vehicles that offsets the efficiency gains they produce.

Enter the Hybrid Air System

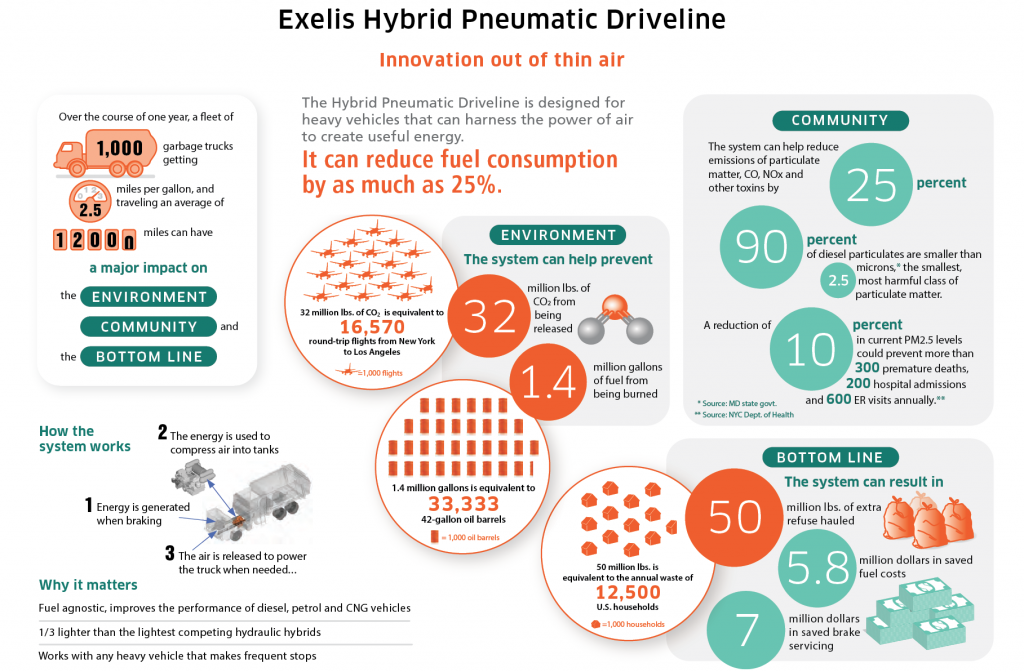

What if it were possible to reduce a fleet of heavy vehicles’ fuel consumption and emissions by one quarter, using only air? Thanks to recent engineering innovations, it is. The first true pneumatic or “hybrid air” propulsion system, designed specifically for heavy vehicles, is already demonstrating clear advantages over both electric and hydraulic hybrids.

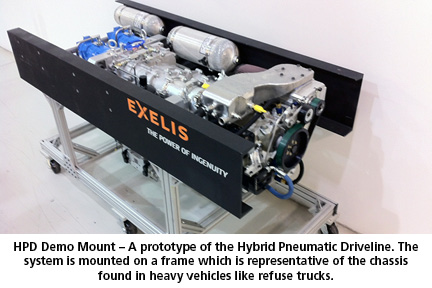

The idea of an air-powered vehicle is not new, but the breakthrough that enabled it is fairly recent. Engineers at Exelis in Amityville, N.Y., a center specializing in high-pressure pneumatics for defense and aerospace applications, figured out how to safely and consistently control very high-pressure air in real-world environments. This innovation gave rise to the first truly feasible “pure air” automotive hybrid system (with no hydraulic motor or components) called the hybrid pneumatic driveline, or HPD.

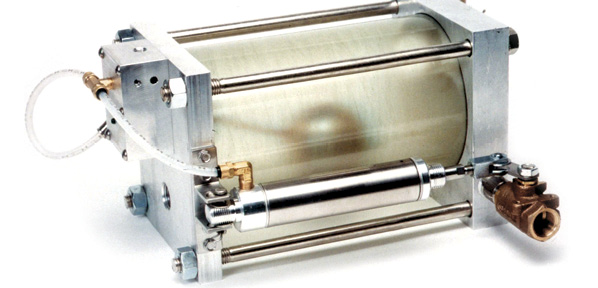

Like other hybrids, the HPD uses regenerative breaking to capture and store energy. When the vehicle brakes, a compressor absorbs energy from the driveline that is stored in the form of compressed air and heat in tanks, rather than in hydraulic fluid or batteries. The weight benefit is immediately clear; no matter how much air you compress, it never gets appreciably heavier.

The captured energy is available to be released into an air motor, providing power for acceleration and reducing the engine’s workload, fuel consumption, and emissions. A pure air hybrid avoids the complications posed by batteries, including limited lifespan, and can convert that stored energy into useable power far more quickly and effectively than electric batteries or hydraulic fluid.

Enhanced Parallel Architecture

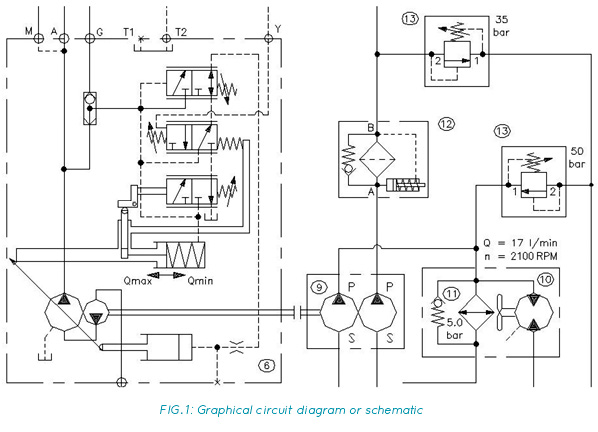

In general, there are two ways an alternate power source can provide power to a hybrid vehicle’s driveline: in parallel, where both sources can turn the vehicle’s transmission simultaneously, and in series, where the internal combustion engine does not power the vehicle directly but a generator, which transmits power to the wheels.

The HPD combines elements of both architectures. By controlling aspects of the vehicle’s normal transmission, this “enhanced parallel” design can realize much of the system efficiency gains of a full parallel system without a radical change to the vehicle’s basic driveline configuration. This approach makes it straightforward to retrofit systems to existing vehicles rather than being limited to new production models.

Designed to Help Make Heavy Vehicles Lighter and Cleaner

The entry point for the HPD will be refuse collection trucks. Lab trials of the system show promising results, and work is underway to begin trials on real refuse collection routes. The benefits of this system over hydraulic and electric hybrids are clear in terms of the efficiencies, which include up to 25% fuel economy and corresponding emissions and particulate pollution reductions, as well as reduced wear and tear on vehicle brakes.

The low cost and inherently longer service lifetime of pure air hybrid technology makes it an attractive prospect for heavy vehicles that make frequent stops, especially when multiplied across large fleets.

Why the Technology Works – and Why it Matters

Compressed air has a fundamental physics advantage over other materials (like hydraulic fluid or batteries) with regard to power density. It provides efficiency gains – fuel economy and emissions reductions – without the cost, weight, or environmental risks associated with electric and hydraulic hybrids. In general, pure air hybrid technology promises to be lighter in weight, more efficient, and cleaner than existing systems.

The high pressures at which the HPD operates were not previously manageable in real-world environments. With that problem solved, the technology lends itself well to a wide range of applications. Regenerative braking on buses, delivery trucks, or railroad cars would be excellent automotive-use cases.

There are many other conceivable applications. Windmills for generating clean energy, for example. In windy locations, excess energy can be stored and used to supplement turbine spinning on quiet days, reducing shocks to power generation and smoothing power supply. The same concept could be applied to wave-generated power.

Most importantly, the technology is readily scalable and can be integrated to any application that would benefit from high power density and light weight. This opens up the possibility of bringing the power of air to a multitude of new applications and industries, which are beginning to realize the importance and potential of clean technologies, not just for safety and the environment, but also for the bottom line.