Emerson Introduces Pneumatic Valve System with Embedded Wireless Connectivity

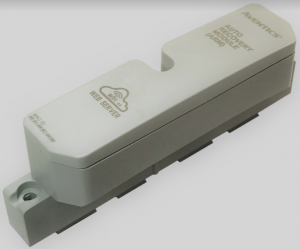

Emerson has introduced a wireless automatic recovery module for its AVENTICS G3 electronic fieldbus platform that facilitates pneumatic valve system commissioning and diagnostics from a mobile phone, tablet, or laptop computer.

Emerson has introduced a wireless automatic recovery module for its AVENTICS G3 electronic fieldbus platform that facilitates pneumatic valve system commissioning and diagnostics from a mobile phone, tablet, or laptop computer.

The new wireless automatic recovery module (ARM) and AVENTICS G3 fieldbus platform are ideal for pneumatic valve system applications in the automotive, food and beverage, tire, packaging, and metalworking industries.

The wireless ARM module provides easy access to the AVENTICS G3 fieldbus platform’s diagnostic and commissioning capabilities via an internal Wi-Fi access point and mobile website – even when the valve system is located inside a machine or on a ceiling. It offers the visual benefits of a hard-wired human machine interface at lower cost and with higher flexibility. To reduce system downtime, the wireless ARM module generates error notification for alarms, voltage levels, short circuits, module errors, open load errors, and distribution errors.

The device has a small footprint and connects easily to the AVENTICS G3 fieldbus platform in the space of a jumper clip. It features three power settings for low-, medium-, or high-distance signals to ensure safe and secure access to data – regardless of where the valve system is mounted. Additional security benefits include a wireless signal that can be turned off during configuration, multiple password options, and diagnostic and commissioning information provided with no control capability.

The wireless ARM module is compatible with Ethernet/IP DLR, and PROFINET protocols. Additional protocols are targeted for future release.

The module also protects the AVENTICS G3 fieldbus platform’s configuration information from a critical failure, including all settable node and attached I/O module parameters.

Emerson also has introduced an upgraded ARM clip for the AVENTICS G3 fieldbus platform that is backwardly compatible to existing ARMs and G3 fieldbus platforms. The ARM clip improves system reliability by protecting configuration information from critical valve system failure.

The AVENTICS G3 fieldbus platform’s electronic parameters and settings are automatically stored in the ARM’s nonvolatile memory and then the ARM is automatically disconnected from power to ensure stored information is not erased during a power spike or critical failure.

The compact ARM module installs in the space of an AVENTICS G3 fieldbus platform’s jumper clip without having to change the mounting.

A replacement G3 fieldbus communication node can automatically download the required parameters from the ARM module, enabling the valve system and production line to quickly resume operation without the need for recommissioning by a controls engineer, offering true plug-and-play capability.

The compact ARM module installs in the space of an AVENTICS G3 fieldbus platform’s jumper clip without having to change the mounting.

For more information, visit www.Emerson.com/AVENTICS.