Endress+Hauser Introduces Products for Fluid Control

Endress+Hauser recently introduced two new products for fluid applications: a temperature transmitter and a flowmeter.

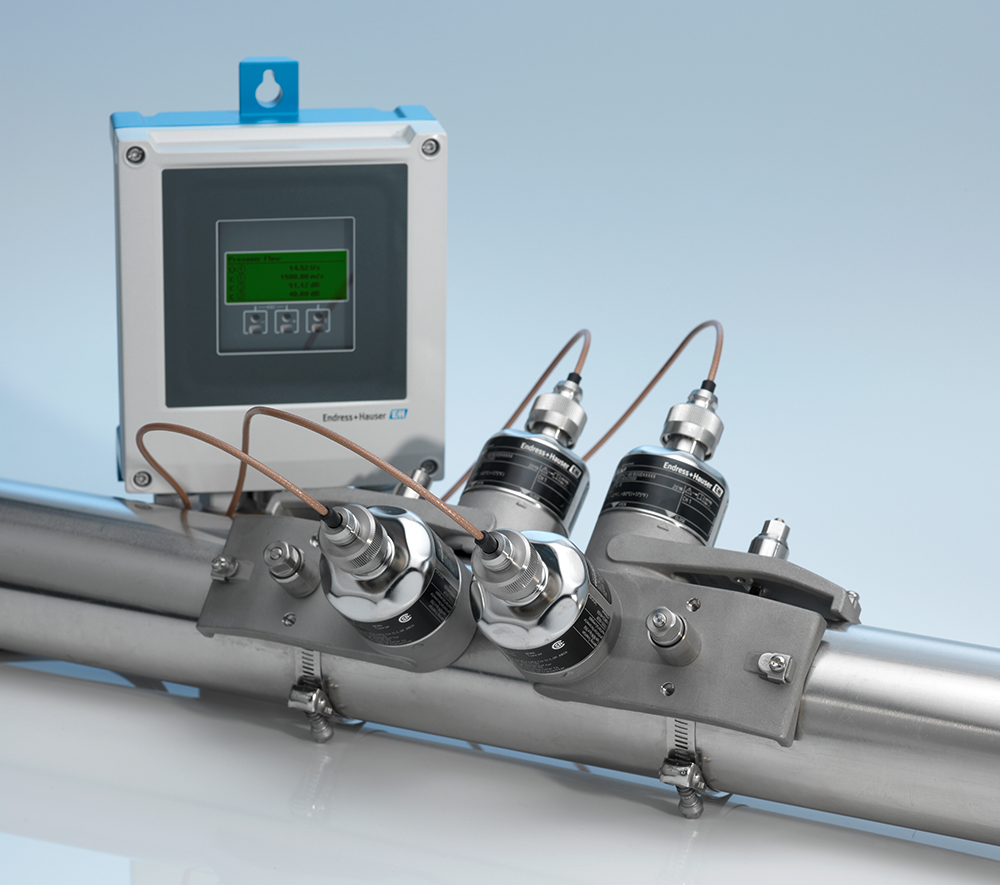

Prosonic Flow W 400

Endress+Hauser’s Prosonic Flow W 400 brings the modern technology of its Proline device series to clamp-on ultrasonic flowmeters.

The W 400 clamp-on and I 400 insertion units provide comprehensive process monitoring with long-term cost efficiency and extensive diagnostics. These sensors pair with Endress+Hauser’s Proline 400 transmitter to provide a complete flow metering solution.

The flowmeter uses a nonintrusive, clamp-on measurement method, with its ultrasonic sensors mounted directly on a pipe’s exterior. This provides safe measurement of many fluids, independent of their conductivity or other properties. This includes corrosive, abrasive, and toxic fluids, making this flowmeter ideal for monitoring countless processes.

Because neither piping nor process flow are interrupted, clamp-on flowmeters can be easily used for retrofitting at any time. They are suitable for low- or high-pressure applications, on pipes smaller than an inch in diameter, and up to 160 inches, such as those encountered in water distribution.

The flowmeter’s IP68 Type 6P submergence-rated ultrasonic sensors are suitable for harsh processes and ambient conditions and can withstand temperatures between –40°F and 266°F (-40°C and 130°C).

Piping systems in the process industry often have multiple fittings and elbows that disturb the flow profile and, along with it, the accuracy of ultrasonic flow measurement. The Prosonic Flow W 400 solution is optionally available with Endress+Hauser’s FlowDC function, which detects and corrects for the effects of flow disturbance. This ensures measurement accuracy even in the presence of a short pipe inlet run, for example when significantly reduced from the standard 15 pipe diameters down to two. The FlowDC function increases flexibility for equipping new or retrofitted systems with clamp-on flowmeters.

Prosonic Flow W 400 can be mounted on a wide variety of pipe types and materials with or without lining. A maintenance-free contact medium, called a coupling pad, provides optimum sound transmission between sensor surface and the pipe, and the resulting high signal strength ensures stable measurement results and long-term reliability. These clamp-on flow sensors are available in multiple ultrasonic frequencies ranging from 0.3 to 5 MHz, optimized for application pipe size, pipe material, and fluid.

For more information, click here.

iTEMP TMT31

The newly developed iTEMP TMT31 temperature transmitter for analog 4-20mA signals is characterized by its long-term stability, high accuracy, and ease of use, making it an important pillar for reliable temperature measurement.

Temperature transmitters are an important link between temperature sensors in the field and higher levels of automation and analysis in the process industries.

The iTEMP TMT31 improves upon its RTD transmitter predecessors with better connection technology, available in two optimized formats. The first incorporates push-in terminals, enabling tool-free, secure field wiring in a matter of seconds. It is also available in the classic screw terminal format, with an optimized design that makes wire terminations in the connection head easier. Corrosion-free contacts ensure maximum reliability of measured value transmission for both connection variants.

For fast commissioning, users have the option to receive the TMT31 transmitter conveniently preconfigured from the factory or to apply custom parameterization on site with free configuration software, such as Endress+Hauser FieldCare or DeviceCare. These software packages run conveniently on a host of operating systems, both on laptops and tablets. The USB configuration kits required for this, such as TXU10 or Commubox FXA291, are also available from Endress+Hauser as accessories.

The TMT31 is approved for safe operation in Zone 2/Div. 2 hazardous areas (nonsparking) in accordance with ATEX and CSA C/US standards, along with Pt100 and Pt1000 sensors. Additionally, the sensor adjustment parameter in the head transmitter can be modified according to Callendar-Van Dusen equations to match the connected RTD sensor characteristics, further refining the temperature measurement accuracy of the entire system.

For more information, click here.