Equal Footing: Swing-Axle Cylinders Manage Uneven Terrain

Marcel Knobloch, Sales Product Promotion, Bucher Hydraulics

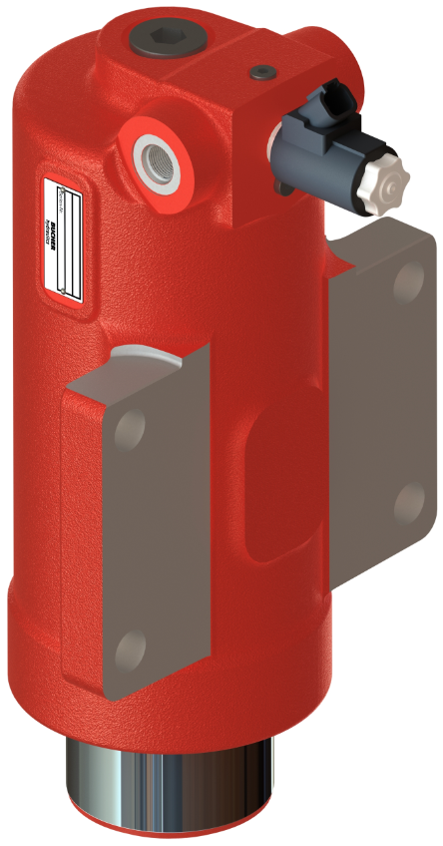

The new generation of swing-axle cylinders from Bucher Hydraulics.

Mobile machines have to meet widely differing requirements. To get to a job site, they need good off-road capability. While they are working, however, they require high rigidity and stability. Added to this are the increasingly demanding safety and environmental regulations. This dual requirement is fulfilled by swing axles, which can be locked when in working mode.

Swing-axle cylinders (SAC) are based on the principle of the plunger cylinder, in which the piston rod serves as the piston. When open (axle unlocked), they enable a vehicle to drive over uneven terrain. The undercarriage can then to a great extent follow irregularities in the terrain without individual wheels lifting up and off the ground. When closed, they lock the axle and thus ensure high rigidity during working operations.

The cylinders are designed for secondary pressures up to 600 bar (8,702 psi) and require minimal installation space. As safety components, they are responsible for the stability of the mobile machine. A malfunction can result in the machine toppling over, with disastrous consequences.

Swing axles are usually attached to the machine undercarriage, while the hydraulic power supply is situated in the rotatable superstructure. This means that the oil supply/return for the cylinders, as well as the control signals for the valves, must be routed through a swivel joint.

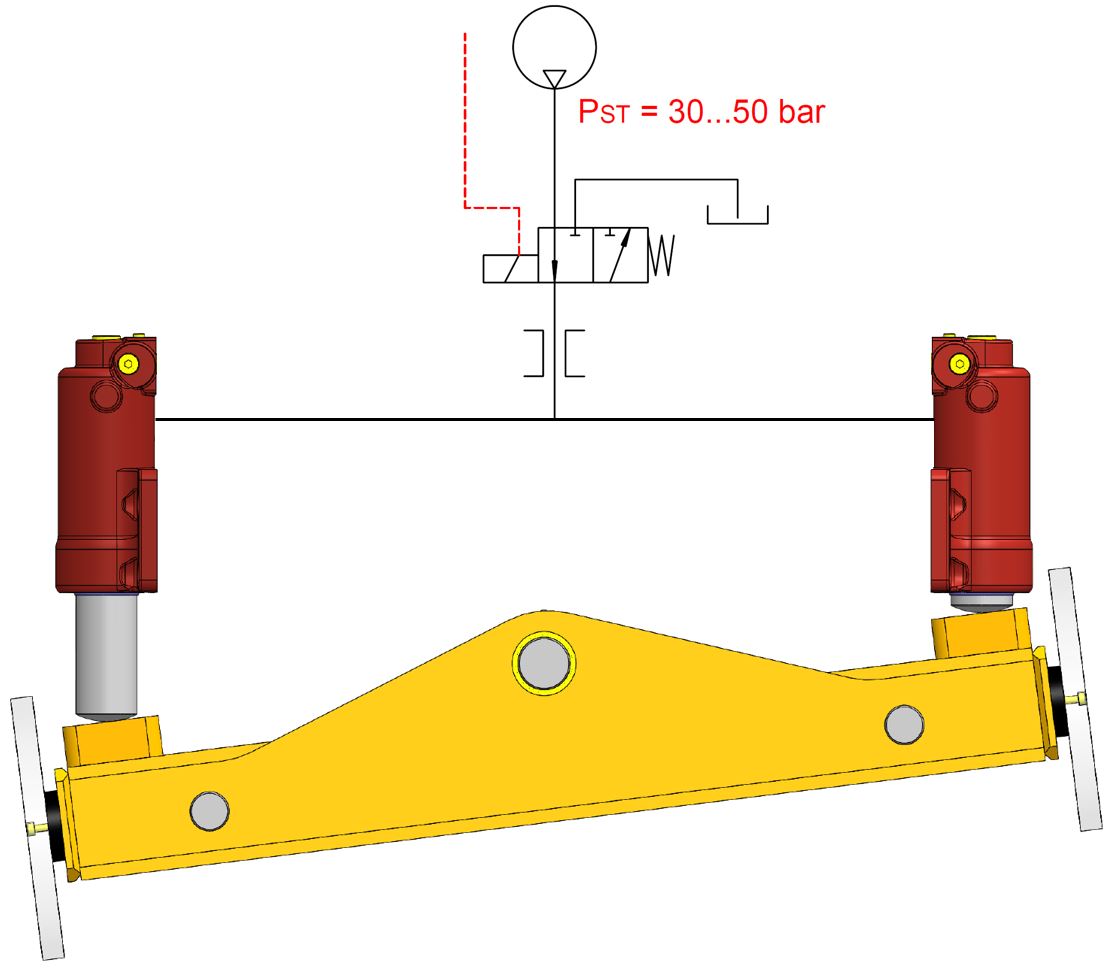

RH series swing-axle cylinder in open (above) and closed/locked positions.

Success from just one line

This was the starting point for the development of the SAC from Erding, which at the time resulted in the RH series (RH from the German for check valve with hydraulic release, i.e., pilot operated). Instead of the usual two separate lines, the developers succeeded in combining the pressure and control functions in one line. The key feature: the valves open or close the flow path, depending on the pressure level. A defined pressure closes the valve. To put it another way, the oil flow fills the cylinders; its pressure switches the valves. This is significantly more energy efficient than the two-line solution.

Getting rid of one line halves the pipework costs, and in addition only one connection through the swivel joint is needed. As well as that, the RH series can be controlled with just one inexpensive 3/2 valve.

The valving in the SAC usually consists of a pilot-operated check valve that traps the oil in the cylinder. When the control pressure exceeds a certain value, the good area ratio within the valve enables it to open against the pressure inside the cylinder. The swing axle is therefore able to move thanks to an exchange of oil between the cylinders.

There are other systems on the market in which the valve opens abruptly when the limit value is exceeded. However, this behavior carries the risk that a heavily loaded cylinder can suddenly give way, causing the machine to tilt or even topple over.

For swing operation, the valves open and the oil can shuttle freely between the cylinders.

A major safety issue with most of these solutions is hose- or pipe-burst. Under no circumstances may it result in instability of the machine. It follows, therefore, that the pressurized oil in the cylinder must be prevented from flowing out. Any outflow that occurs must be restricted to a very slow rate.

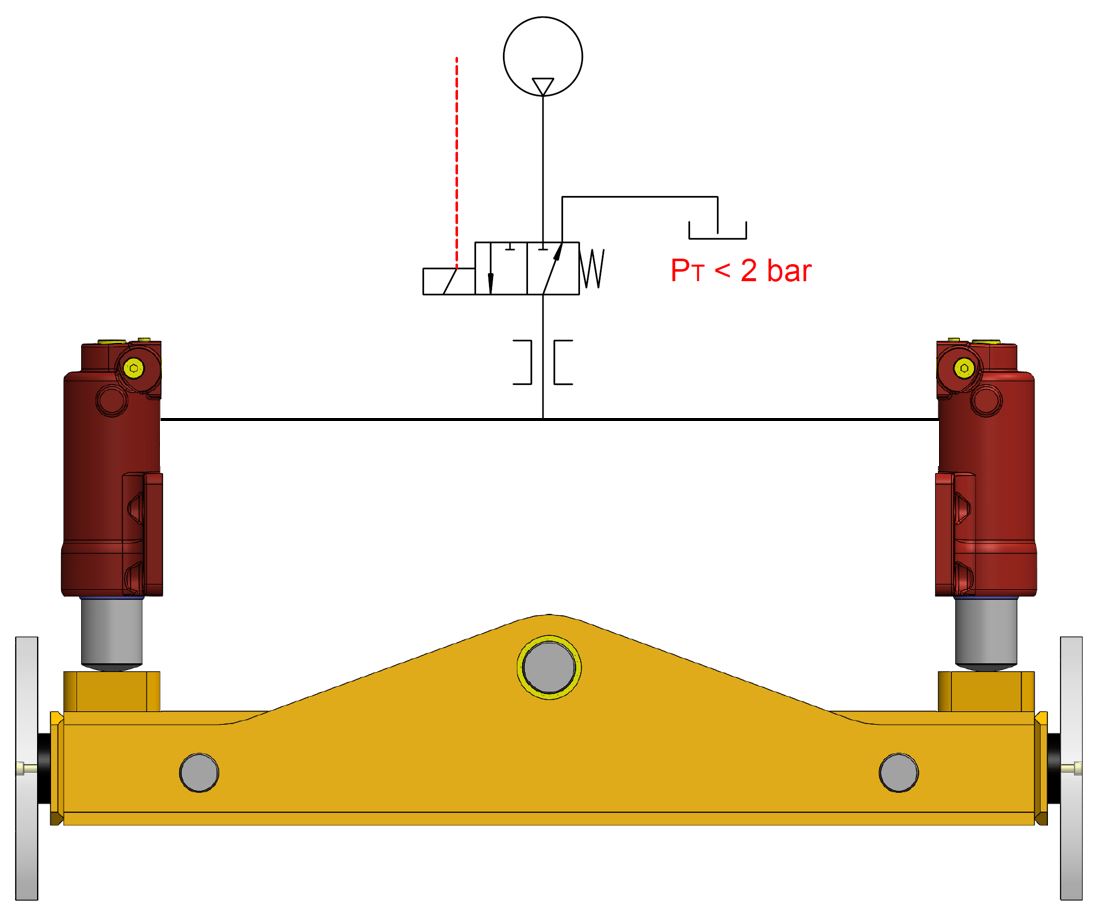

The newly developed and patented DRH (throttle check valve, pilot operated) complements the Bucher Hydraulics SAC range. In essence, it is a check valve with an additional flow control function. The valve sits in a cartridge that is mounted axially in the cylinder and includes the port for the hydraulic line.

Inside the cylinder, the check valve is series-connected with a flow control valve that throttles the outflowing oil. This throttling improves travel comfort and guarantees a safe switchover from swing mode to work mode.

One further advantage: in line with the modular-system principle, we now have a standard cylinder plus screw-in cartridge valves with DIN or UNF threads. This reduces inventories and improves serviceability.

Preload integrated in the valve

Oil compressibility and other effects result in a settling of the machine. This results in a few millimeters of clearance between the cylinder rod and the axle pad on the unloaded side, which can lead to increased wear if the load changes.

With the DRH valve, when the swing axle is in locked mode it can be recharged with only one line by applying a specific tank preload pressure. This forces oil into the unloaded cylinder, and the piston rod then rests firmly on the axle without any gap. For the machine operator, this means stiffer and more controllable machine behavior.

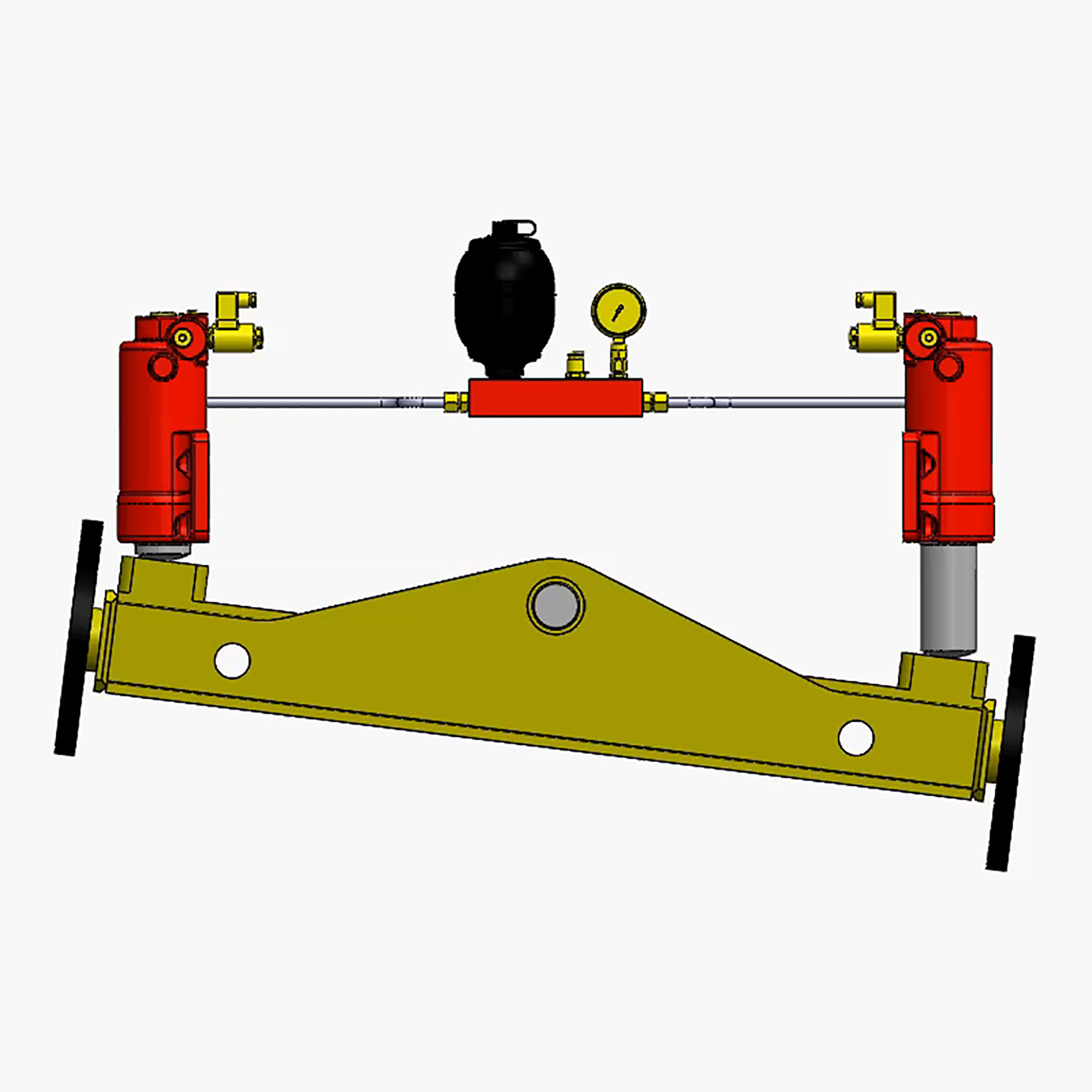

The RM swing-axle cylinder for electric machines.

The integrated throttle check valve dampens any pressure peaks that may occur in the control line when the SAC is unlocked, thus preventing possible damage.

The valve is extremely compact and requires little installation space in the SAC’s body, which is a machined casting. In the event of a pipe- or hose-burst, the valve closes automatically and goes into the closed/locked position.

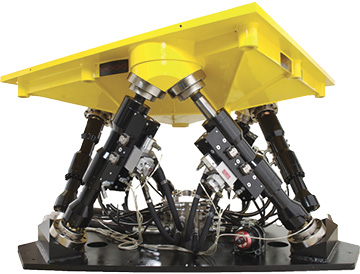

RM for an electrified future

E-mobility is also making inroads into mobile machinery. At present it is still only the smaller machines that use electric drives, but the trend is clear.

Bucher Hydraulics is more than prepared for this development. The type RM cylinder is the ideal solution. Basically, it is a closed system in which the oil just shuttles between the two cylinders.

In this case, an electrically actuated valve performs the control function. The system needs only one electrical line through the swivel joint.

Due to kinematic effects, small stroke differences may occur. These are compensated by a small oil accumulator, which also provides constant pressure. This ensures the same machine stability as with the DRH cylinder. The only external connection required is an electrical one: hydraulically, the system is completely self-contained. •