Grip on Reality: Pneumatic Tooling in Automation Robotics

By Frank Langro and Mike Guelker, Festo

As implementations of stationary and autonomous mobile robotics grows, the focus on innovations in end-of-arm tooling technology intensifies. End-of-arm tooling innovation falls into two broad areas. The first involves designing new and improved specialized tools for performing single-purpose tasks such as gluing or screwdriving. In the second, design engineers work toward solutions that expand flexibility in picking and placing, holding, and clamping. The greater the range of objects grasped by a gripper, the more a single robot can do and do efficiently.

Pneumatic- and vacuum-powered grippers are applied in numerous industries and applications due to their small-form factor and high-force capabilities as well as the lower relative cost of pneumatics compared to servo-electrics. Pneumatics and vacuum are also ideal for adaptively gripping variable shapes and delicate, easily damaged objects. Servo-electric grippers are primarily used for precision, low-force gripping and have a narrower band of applications compared to pneumatics.

In some cases, unique designs rather than force, size, and cost make pneumatics the ideal choice. In one recent customer application, a pneumatic cylinder incorporated a vacuum assist and blow-off function via a hollow through rod on the cylinder. Compressed air flowing from the through rod removed debris and protected the workpiece surface.

Demand for flexible automation

The COVID-19 pandemic has accelerated interest in flexible automation. Automation reduces worker density, lowering the risk of airborne germ transmission. Flexible automation also helps lower dependence on a labor market in which too few skilled workers are applying for open positions and serves to counteract the rising price of labor.

The development of autonomous mobile robots has moved robotics into new applications. Robots today, for example, can sanitize areas of a facility between shifts and other transition periods. The implementation of robotics for these tasks makes it possible to sanitize more often, thus protecting patients, guests, staff, and workers in hospitals, hotels, and plants. Due to the variety of tasks diverse types of grippers could be needed to accommodate different sanitizing tasks.

New materials, controls, manufacturing innovations such as 3D printing, and energy management for greater sustainability are driving innovation in robotic gripping. The ideal gripping solutions are typically lightweight and handle a variety of objects. This means that most gripping solutions no longer consist solely of heavy-duty metal parts. Today, 3D-printed and molded parts are increasingly incorporated

into grippers. The speed and versatility of 3D printing allows for

customized gripper fingers to handle specific objects. Companies that can 3D print gripper fingers internally are less susceptible to supply chain disruption and better equipped to make repairs and modifications rapidly, which positively impacts uptime and productivity. A rapid prototyping capability provides companies with greater agility and can help them adapt to a rapidly changing environment.

Artificial intelligence

Artificial intelligence and smart pneumatics also play a part in furthering pneumatics gripping applications. AI, smart pneumatics, and gripping are simply a natural fit. The ability to adjust and control grip force based on the attributes of the object is useful in applications in which the objects being grasped can vary. As the AI system recognizes the object, with a pneumatic gripper pressure can be adjusted to apply the appropriate gripping force or vacuum level to hold the part securely without causing damage.

AI and smart pneumatics are making great strides in terms of not only adjusting force but also in the flexibility of the “grasp.” The human hand has 27 degrees of freedom, enabling it to grasp and manipulate many different objects with varying force. In production environments, this level of flexibility would eliminate changeovers in tooling and prevent production interruptions. In distribution centers, handlike gripping accelerates the adoption of robotic picking and packing. And in agriculture, flexibility facilitates planting and harvesting, particularly of fruits and vegetables.

Robot with parallel grippers for versatile picking and placing boxes in a warehouse.

Food processing and the handling of meat, poultry, and fish require high levels of sanitation. Soft gripping solutions made from food-safe materials can prevent contamination from being introduced to the food stream and can be easily disinfected. As soft grippers come into contact with these food items, they gently shape around them without harm. Pneumatics with its inherent cushioning makes this possible.

Similar soft gripping solutions for agriculture are rapidly developing successful strategies to deal with inconsistency in shape, sizes, and ripeness. Mobile robots with AI-based systems in tandem with soft gripping are learning to differentiate fruit and vegetables that are ready to pick from those that are not. Labor shortages along with the emergence of indoor and vertical farming are drivers of new robotic applications in the agricultural space, opening the door to a host of soft gripping applications.

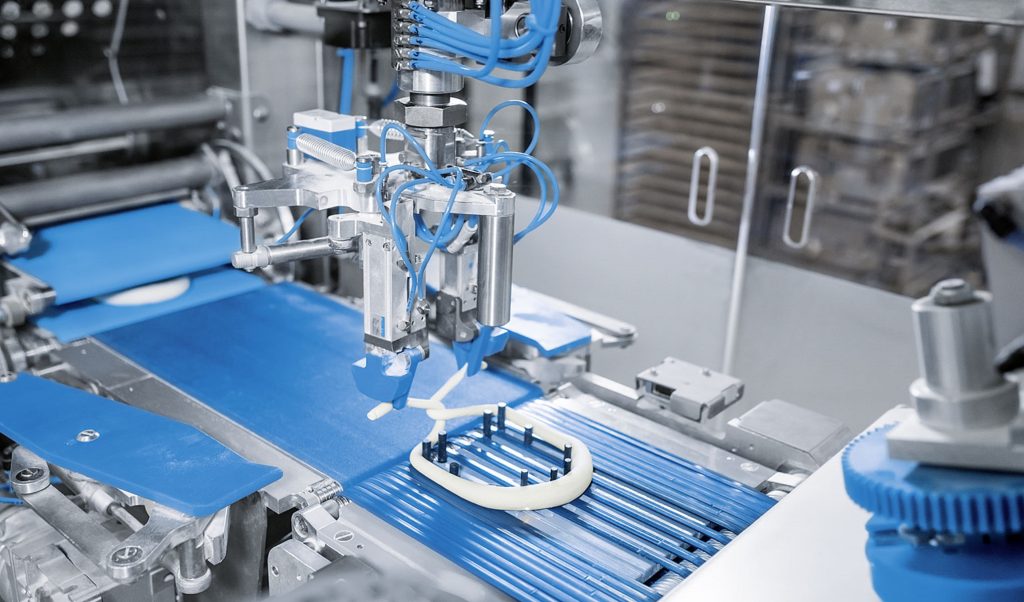

Adaptive grippers in a bakery gently grasp dough in a high-speed pretzel-making process.

Autonomous mobile robots

Stimulating profound change in automation is the marriage of autonomous robotic mobility with flexible gripping. In manufacturing and end-of-line packaging, work comes to the robots; the robot does not go to the work. Using autonomous mobile robots with flexible gripping, robots travel safely among humans and go to the work. This is happening in hospitals and distribution centers were people and robots safely inhabit the same environment. For these applications, innovative, compact, portable, and low energy consumption compressors are being introduced.

Parallel pneumatic gripper.

The most common types of industrial pneumatic robotic grippers are parallel, three-finger, angled, and vacuum. Parallel grippers, the most frequently applied, do just what their name implies: two slides either close parallel to the workpiece to grip its outside edges or open out to put pressure on inside walls.

Three-finger grippers are used to center the workpiece between the fingers, which are offset by various angles. The three fingers slide the workpiece to the gripper’s center, holding the workpiece snugly. A variation of the angled gripper is the radial gripper: The fingers open a full 180˚, which is useful where vertical space is limited. Fully open radial fingers can rest just above or below the workpiece and close when it is in position. Vacuum grippers can be as simple as a single suction cup or as complicated as a 12-x-12 matrix with different configurations of cups fed vacuum as needed to conform to various shapes and weights of the load to be grasped.

Adaptive gripping is a new class of gripper. These grippers offer flexibility in the range of objects they can grasp.

Mention adaptive grippers to anyone in manufacturing or assembly today and their first response will be to say adaptive grippers are being developed for collaborative robotics. They would be partially correct.

Just as important as collaborative robotics, other industries are driving development principally because the price of automation is falling, and the capabilities are rising. For example, dairy farming is a labor-intensive agricultural business with low margins and a shortage of workers. Due to technology advancements, there is a trend toward dairy farms incorporating robotic milking barns where cows learn to enter the barn to feed and, at the same time, be milked by a milking robot – all without human intervention. In the baked-goods industry, soft-adaptive grippers gently grasp breads and muffins. These flexible robotic systems can pick and pack mixed assortments to conform to each customer’s order.

Just as important as collaborative robotics, other industries are driving development principally because the price of automation is falling, and the capabilities are rising. For example, dairy farming is a labor-intensive agricultural business with low margins and a shortage of workers. Due to technology advancements, there is a trend toward dairy farms incorporating robotic milking barns where cows learn to enter the barn to feed and, at the same time, be milked by a milking robot – all without human intervention. In the baked-goods industry, soft-adaptive grippers gently grasp breads and muffins. These flexible robotic systems can pick and pack mixed assortments to conform to each customer’s order.

For items that are oddly shaped and not easily damaged, adaptive grippers with metal or hard plastic hinged fingers can be used for grasping. For items easily damaged, such as produce or baked goods, the pneumatic fingers are made of a flexible elastomer. Some elastomeric grippers have flexible zones and nonflexible zones. When pressurized, the flexible zones inflate and flex around the nonflexible zones, creating a nonmechanical hinge. Elastomeric fingers do not damage an item because both the elastomer and compressed air give when in contact with an object and thus offer a built-in cushioning effect. This inherent damping causes less shock during initial grasp, making these grippers ideal for baked goods, confections, fruits, and vegetables.

The continued advancement of adaptive gripping will rely in varying degrees on:

- Tactile force sensors for measuring force and detecting different objects.

- Flexible printed circuit board with inertial and force sensors.

- Compact valve terminal with proportional piezo valves for rapidly and precisely ventilating and exhausting individual gripper fingers and swivel modules.

- Inertial sensors for recording the position of the gripper fingers.

- Elastic silicone skin for improving the haptics (the experience of simulated touch) and protecting the sensors.

- 3D textile knitted fabric of high-strength synthetic fibers for long wear.

- AI for reinforcement learning.

- Vision systems for identification and location sensing.

There are drawbacks to adaptive grippers. They open and close more slowly than comparable stroke conventional grippers. Elastomeric materials wear faster than metal or hard plastic. The size and weight of objects limit what these grasping devices can manage.

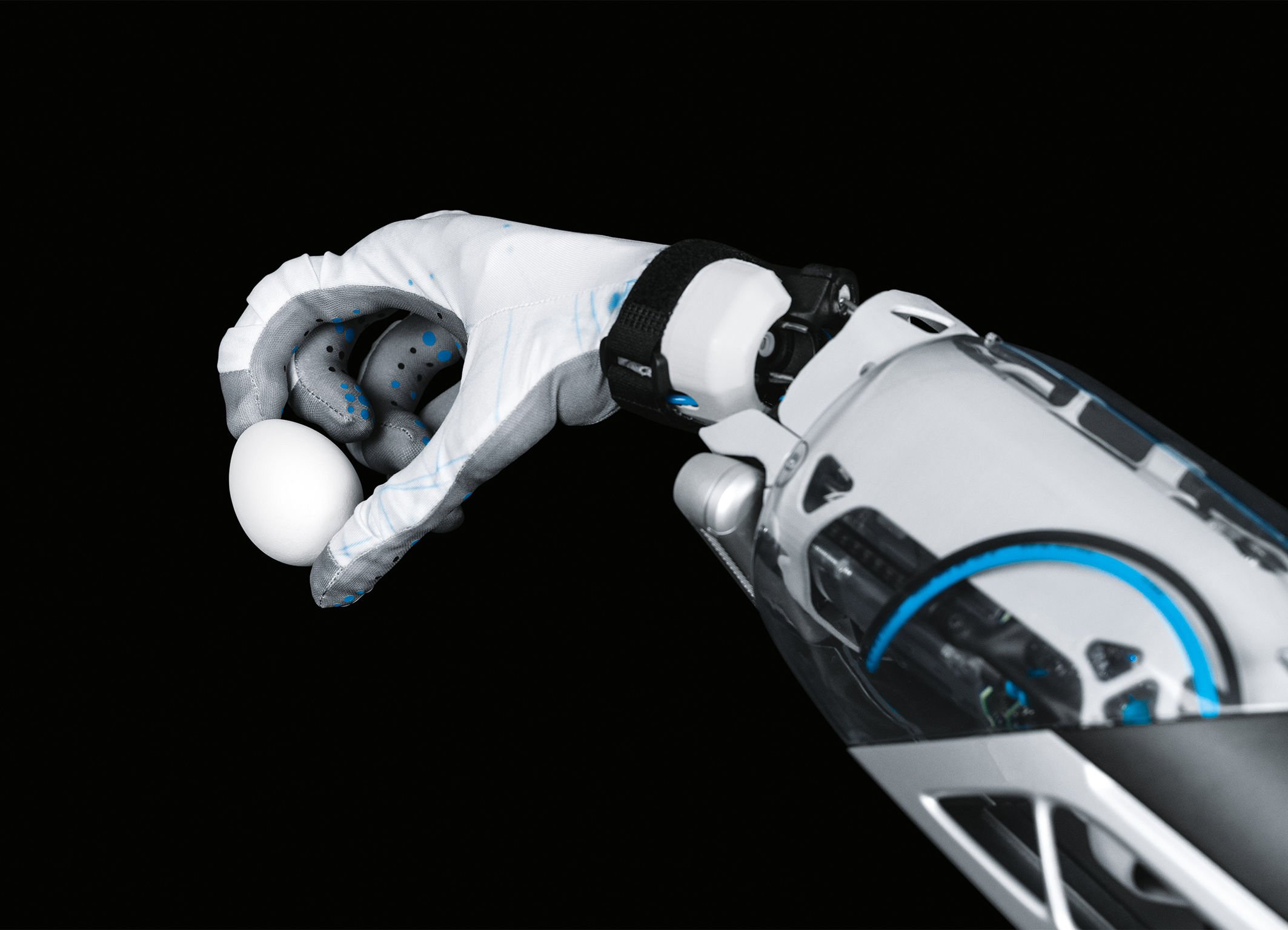

The greatest area of exploration for the future of adaptive gripping will be simulating the functionality of the human hand. The reason for this is simple. The hand offers the greatest efficiency – one gripper for a wide assortment of tasks. And with sensor technology providing touch feedback there can be object manipulation, something grasping finger-based grippers cannot do.

Shorter product lifecycles, small lot sizes, and labor demographics are accelerating the need for adaptive systems. There are fluid power engineers today envisioning the possibilities and moving the industry forward. For a fluid power engineer, the opportunities for innovation in this field are endlessly gripping.

The Bionic Mobile Assistant Prototype

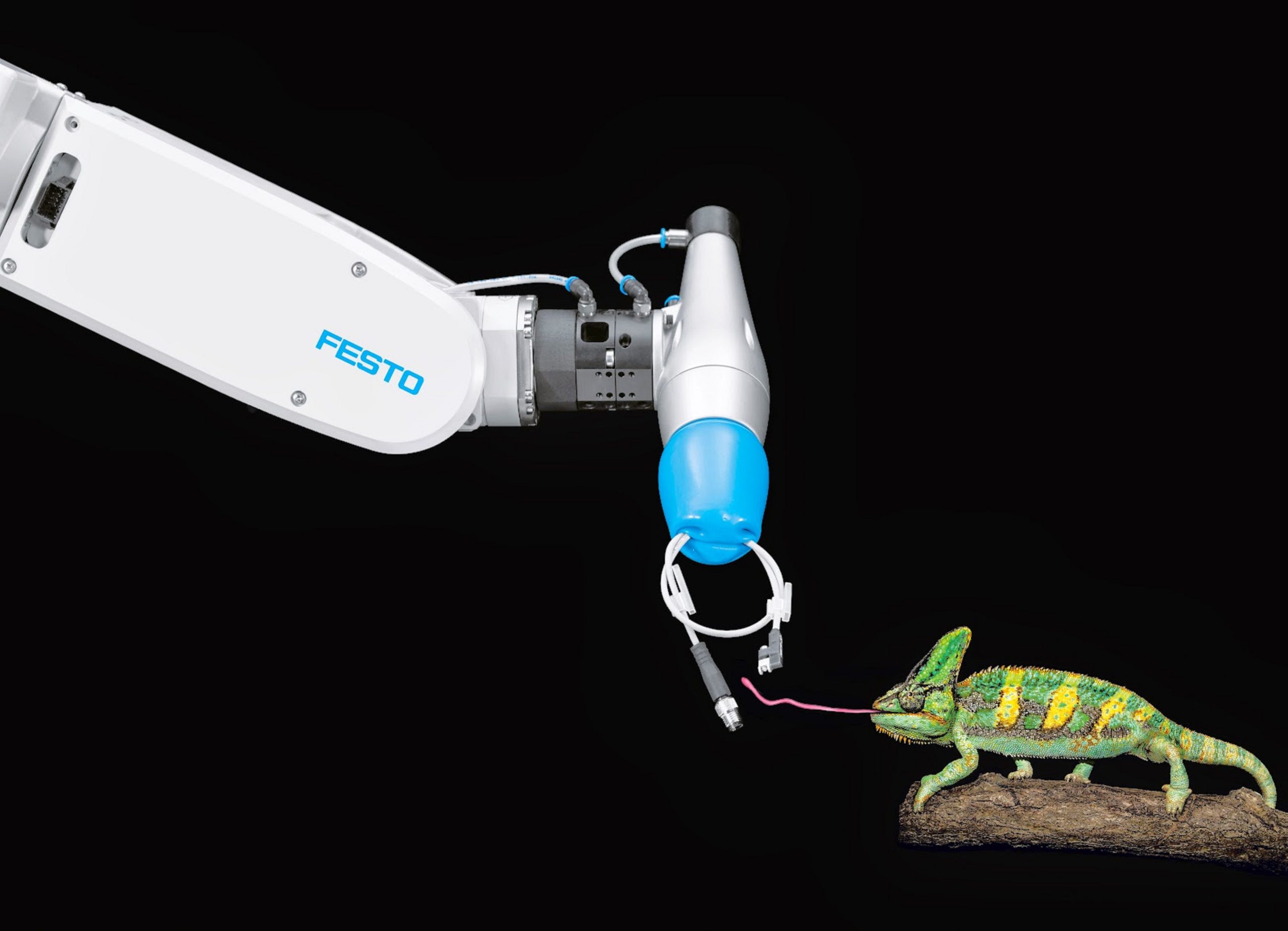

Industrial change demands new kinds of interaction among people, machines, and data. In the future, operators and robots will interact closely together, so Festo has been working intensively on systems that can relieve people of monotonous or hazardous activities while at the same time posing no risk. Artificial intelligence plays a significant role here. The BionicMobileAssistant is a prototype of a robot system that moves independently in three dimensions and can identify objects, grip adaptively, and collaborate with humans.

The entire system, which has been developed in collaboration with ETH Zurich, has a modular design and consists of three subsystems: a mobile robot, an electric robot arm, and the BionicSoftHand 2.0. First presented by Festo in 2019, the pneumatic gripper mimics the human hand.

With its unique combination of force, dexterity, and fine motor skills, the human hand is a true miracle of nature. To enable the BionicSoftHand 2.0 to replicate the movements of the human hand, compact valve technology, sensors, electronics, and mechanical components are integrated in the tightest of spaces. The fingers and the opposable thumb are made of flexible bellows structures with air chambers surrounded by a firm yet yielding knitted fabric. This makes the hand light, adaptive, and sensitive, yet capable of exerting strong forces. The pneumatic fingers are actuated by a compact valve terminal with piezo valves mounted directly on the hand.

In order to extend the maneuverability of the thumb and index finger compared with the first version of the BionicSoftHand, the developers increased the lateral swivel range of both fingers. As a result, they now work well together and grip with great precision. Thanks to a 3D-printed wrist with two degrees of freedom, the hand can also move both back and forth as well as to the left and to the right. This means that gripping with a tight radius is also possible.

To increase the stability of the fingers, the air chambers now each contain two structural elements that function as bones. For each finger, a bending sensor with two segments determines the positions of the fingertips. The hand also wears a glove with tactile force sensors on the fingertips, the palm, and the outer sides of the robot hand. This allows it to sense the nature of the item to be held, and to adapt its gripping force to the particular item – just as people do.

In addition to the tactile sensors, the hand has a depth camera inside the wrist so it can visually detect the objects. Using it, the robot hand detects and grips a range of objects, even when they are partially covered. Once the hand has been correctly trained, it uses the collected data to assess the objects and distinguish good from bad, for example. The information is processed by a neural network that’s been trained in advance with the aid of data augmentation.

Electric arm

The BionicSoftHand 2.0 is combined with a mobile ballbot and a lightweight electric robot arm – the DynaArm. The DynaArm can carry out fast and dynamic movements thanks to its lightweight design with highly integrated drive modules that weigh just 1 kilo (2 pounds).

For the ballbot, the developers chose a sophisticated drive concept: the robot balances on a ball. This means that the BionicMobileAssistant can move freely in all directions. All the system’s energy supply is onboard: the battery for the arm and robot is located in the body; the compressed air cartridge for the pneumatic hand is installed in the upper arm. The robot is thus not only mobile but also works autonomously. The algorithms stored on the master computer also control the system’s autonomous movements. The robot orients itself independently in three dimensions using two cameras.

Hand in hand with people

The system would be perfect to directly assist people, as a service robot, as a helping hand in assembly, or to help carry out ergonomically strenuous or monotonous tasks.

It could also be used in environments where people cannot work because of hazards or restricted accessibility, such as maintenance or repair work, data measurements, or visual inspections. Imagine mobile robots carrying out simple tasks in areas of risk infection. Other future scenarios include robots bringing drinks and food to the table in restaurants or delivering medicines to hospital or nursing home patients.

Thanks to the modular concept, the BionicSoftHand 2.0 can be quickly mounted on other robot arms and is easy to commission. Combined with Festo’s BionicCobot or BionicSoftArm, the gripper can, for example, form a completely pneumatic robot system that works hand in hand with people.