HKS Develops Advances to DA-H Rotary Actuators

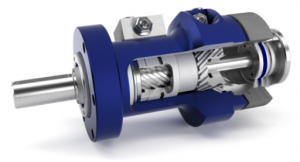

The I-DA-H universal actuator made by German company HKS is an advanced development of the hydraulic DA-H rotary actuator.

The I-DA-H universal actuator made by German company HKS is an advanced development of the hydraulic DA-H rotary actuator.

The I-DA-H is a helical rotary actuator based on a multiple helical gear. The linear movement of the piston is converted into a rotational movement via the multiple helical gears. The longer the linear movement of the piston, the greater the rotational movement. The outer dimensions of the innovative I-DA-H are flexible with regard to design, and it offers many technical features. The rotary actuator is suitable for use with working pressures up to 250 bar (3,626 psi) and for torques up to 250,000 Nm.

In its standard version, the I-DA-H has an angle of rotation of up to 360° and a special angle of rotation of up to 1,500°. Any intermediate rotation angle is possible, so the rotary actuator can be integrated seamlessly into existing systems. No external end stops are required because the pistons can be run to their end stop positions and loaded. Thanks to optimized end-position cushioning, which is standard, the mass moment of inertia is decelerated smoothly. This allows the I-DA-H to relieve the load on the machine and increase the service life of the entire system.

All sliding surfaces and gearing are surface hardened, so the rotary actuator is subject to almost no wear and its effectiveness is maximized. The standard camshaft enables sensing of the angle of rotation and end position. The I-DA-H is equipped with state-of-the-art sealing technology, which increases the safety and service life of the machine considerably because internal leaks are prevented and wear is minimized. Practical features also include the infinitely variable adjustment of the shaft position, the improved support with four-point bearings, and standard angle adjustment.

For more information, visit https://www.hks-partner.com/en/home/.