Injection Molding Machine Hydraulic Retrofits

By Alan Wheatley, Motion Repair & Services

Wheatley is a MOTION Branch Manager and has over 35 years of fluid power industry experience.

Plastic injection molding machines are key components in many manufacturing industries, including food and beverage, automotive, pharmaceutical and construction. Some machines have operated for decades and continue to produce quality parts, albeit at a reduced capacity. However, machine users get increasingly frustrated with trying to find the parts required to maintain the machines without OEM support, as most have stopped servicing older models.

Mechanically, the machines are robust, but the hydraulic and electrical components tend to be older technology or OEM-specific, requiring constant maintenance or replacement. Upgrading the hydraulic components and systems to newer technology will enable users to extend machine life while improving performance, increasing productivity and reducing unscheduled downtime. Additionally, many Tier 1 users of plastic molders are demanding guarantees that the machines are in proper working condition and will not impact production.

Upgrading the hydraulics on injection molding machines can be accomplished in multiple ways:

- Removing OEM-specific or obsolete components and replacing them with standard products with technical advantages.

- Adding IIoT sensors to provide machine performance feedback for monitoring and predictive maintenance.

- Installing contamination sensors, water sensors and improved filtration products to ensure fluid is kept in optimum condition.

- Changing fixed-speed pump-motor assemblies to variable-speed versions to match flow and pressure output to machine demand (which can offer significant energy savings).

- Upgrading electrical control systems to provide local and remote capabilities for fault diagnosis.

Figure 1 – Original Installation

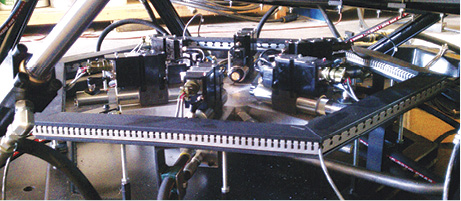

Figure 2 – Upgraded Installation

This conversion is for an injection manifold on an injection molding machine. Because the machine is obsolete, OEM parts and support are scarce. The conversion uses mostly standardized components with a simpler custom manifold solution designed by Motion, saving costs for the end user. Images courtesy of Motion.

Conversion of OEM components to standard product

Over the years, many injection molding machine OEMs have used custom hydraulic components supplied by their preferred manufacturers. These OEMs work with hydraulic manufacturers to design components to their specific requirements that are frequently proprietary to the machine builder. While this helps the OEM in the aftermarket, this practice also limits competitive product options for users who purchase their machines. Users cannot buy the products direct from the hydraulic distribution channel and must go to the OEM for replacement parts, often at inflated cost. Additionally, continuing aftermarket parts support is reduced as the machine’s age will dictate if the OEM is willing to provide parts to the end user. Sometimes, customers need to go to the internet or surplus parts providers just to keep their machines running.

Contacting a reputable technical fluid power distributor with experience in plastic machinery could yield recommendations on replacing the OEM-specific obsolete components with more readily available equivalents. Value-added technical distributors will look at the machine systematically and provide alternatives the user may not have considered. An example could be using proportional control valves instead of standard on/off valves or complete manifold assemblies for power, injection or clamp functions. Converted manifolds (Figures 1-2) often utilize newer technology components, simplifying the circuit design while improving performance and reducing heat generation—which is wasted energy.

Monitoring and predictive maintenance opportunities

Recent technology in IIoT sensors has given injection molding machine users real-time information on machine status to reduce unnecessary downtime. Unscheduled downtime of a high-production injection molding machine can significantly impact productivity and create scheduling headaches. IIoT sensors can provide continuous feedback on key machine parameters such as pressure, flow and temperature to confirm that all are within the recommended guidelines for optimum performance.

This information can be displayed locally or on a plant-wide dashboard on the user’s network. Maintenance and production personnel will be notified if a machine parameter is outside the recommended value, allowing the machine to be taken out of service before a catastrophic failure occurs. Additionally, continuous machine monitoring lets production managers predict when a machine may need to be removed from production for routine maintenance. Maintenance managers will be allowed to properly schedule machine service and ensure the required parts are available to complete the task in time.

Filtration system installation and fluid monitoring for improved fluid performance

An estimated 85% of hydraulic component and system failure is due to poor fluid quality. Most issues are related to contaminated fluid, but water content, elevated temperatures and machine fluid type are additional contributing factors to fluid health. Injection molding machines are high-pressure, high-speed and high-temperature applications. These extreme performance factors have an impact on fluid. How well the fluid is maintained likewise affects equipment performance. Many injection molding machines of the past did not provide proper filtration or temperature control. Additionally, recent fluids have had key additives removed to reduce environmental impact. This new formulation has made fluids more susceptible to varnish generation, leading to component malfunction, obstructions in heat exchangers and blockage in filter elements.

A crucial advance in fluid engineering is fluid sensors and high-performance filter elements that monitor and combat varnish generation in injection molding machines. These sensors observe contamination and water saturation, plus provide real-time feedback on fluid-quality status. Ensuring the fluid is maintained within the recommended guidelines for the hydraulic system reduces unwanted costly downtime. As filter manufacturers better understand how these new fluids perform in these difficult applications, they update their filter element media and designs. The updates provide static-free elements that can counter the creation of varnish and other elements designed to remove varnish and free-standing water from the fluid. Adding these fluid sensors, filter elements and system upgrades can improve productivity.

Variable-speed pump-motor assemblies to match flow and pressure to machine demand

Most injection molding machines use various pump-motor assemblies to meet the hydraulic power demand of the machine cycle. These can be fixed-displacement or variable-volume pumps, or a combination of both. However, these pumps are typically connected to a fixed-speed electric motor, which runs at a constant speed regardless of duty cycle. Injection molding machines have dwell times during their machine cycle where the flow or pressure requirements change. These dwell times are an opportunity to introduce variable-speed pump-motor assemblies that will match the machine’s power demand, reducing energy consumption and CO2 emissions. Electrical power costs are always increasing, and the ability to reduce energy costs will benefit the facility’s bottom line in the long term. It also allows the facility to reduce its carbon footprint and impact on the planet, reducing associated gas emissions by as much as 70%.

Additional benefits of variable-speed solutions are lower noise, reduced cooling requirements, simpler circuit design and connectivity to machine control systems. Lower noise levels could decrease the need for costly noise enclosures, while reduced energy losses may result in less water usage or removing heat exchangers altogether. Simpler circuit designs can be realized as the pump motor will vary the flow rate based on demand. The hydraulic circuit could allow users to remove costly proportional or servo valves and replace them with simpler on/off valving. As noted, changing the pump-motor assembly from fixed to variable speed could significantly improve the machine.

Upgraded electrical control systems for improved performance and remote diagnosis

Electrical control systems are the brains behind injection molding machines. They control all the machines’ functions, including hydraulics, safety, barrel temperatures and speed control. Older machines have obsolete controls that make part replacement difficult or have limited control capabilities compared to newer versions. Additionally, some machine OEMs have proprietary control systems allowing only their technicians to access the program and service the machine.

Upgrading the electrical control system with off-the-shelf components with assistance from a qualified injection molding machine control specialist will minimize your dependency on OEM-specific parts and services. Having a control specialist upgrade the electrical system will give control back to the user to monitor and modify the machine’s performance to suit the specific application. Most new control systems are faster and more precise and allow remote access for troubleshooting and modifications by the specialist. Finding replacement parts will be easier using standardized products if failure occurs. Overall, upgrading your electrical control system is important to improving machine performance.

As older injection molding machines continue to operate as expected, there are many ways to upgrade them to improve performance and productivity. If the machine is mechanically sound, implementing these upgrades will improve performance and productivity and minimize unscheduled downtime. Engaging a third party with experience in this specialty can bolster your operation’s short- and long-term efficiencies.