Land & Sea: Adapting Land-based Pressure-sensing to Deepsea Technologies

By Greg Pinto, Product Manager, Electronics (Sensors and Diagnostics), Hydac USA

Some advances in safety and innovation in the Oil & Gas industry were first made with land-based technology and then adapted to subsea technology. For example, let’s consider the areas of pump control and circuit status switches. The critical part of isolating a dangerous well kick due to piercing a gas pocket or a downhole explosion is the BOP (Blowout Preventer) system. In both existing and legacy-design BOP systems, pressure switches that were very popular—adjustable, mechanical pressure switches indicating circuit status sensing and pump control motor starter firing—were used. This is now an extremely antiquated technology. These switches have bi-metal spring or Bourdon tube components for their repeatable set points and are affected by aging metals, rusting, humidity effects as well as shock and vibration. This constant “change” causes set points to drift and require a constant check/re-check process to be sure set points haven’t drifted from acceptably safe levels.

Our invention of electronic switch technology nearly 40 years ago eliminated the issues associated with mechanical switches. Even so, relative to the Oil and Gas market, change comes very slowly with electronic devices. Once we had switches approved by ATEX, IECEx and CSA as explosion/flameproof, customers began their integration and wondered why they waited so long to change. Our feedback is they prefer the tech advancement, stating once they install an electronic switch, it’s checked and verified during the factory acceptance test (FAT) and then it’s ready for years of trouble-free service. Once in-the field, the electronic switch does not have to be continually monitored. Remember, a pressure switch is a pressure transducer with only an additional switch ASIC (Application-specific Integrated Circuit Board). Even though the Bureau of Safety and Environmental Enforcement (BSEE) and the Minerals Management Service (MMS) each requires a quarterly check of sensor accuracy and switch points, electronic set-points rarely need attention.

Another benefit of electronic pressure switches is the ability they give you to set your normally open, normally closed functionality electronically and to set points from 5-100% of the pressure range. The expected life of 100 million cycles confirms the “set-it-and-forget-it” capability. A simple program allows you to reset on the fly (takes 45 seconds) without the need to pressurize a circuit to be able to set the switch(s) points (which could take 10-20 minutes each). The program also gives you the capability to specify a delay of up to 2 seconds between the set point of the pressure and the actual change of state of the switch, allowing the user to eliminate the switch on/switch off of pump relays, motor starters and circuit status lights which cause uneasiness and can damage components in a system.

This same pressure switch/transducer design criteria used in land-based technology has been integrated into our Subsea Deepwater pressure sensing technology with one enhancement, seawater depth compensation. This compensation can be accomplished using the DCA filled compensated pressure OR the direct seawater as direct compensation technology.

When we first witnessed how Deepwater pressure transducers require a second transducer to sense water depth pressure and then “subtract it” from the system process pressure, we felt we needed a better approach since currently there were additional costs in programming and components to do a simple pressure reading. As a result, we took the initiative and involved our Research & Development department to develop a better solution. Our goal was to eliminate this extra step by removing the water depth head pressure within the transducer itself, outputting the system pressure via one, 4-20 mA signal. This was the birth of the direct compensated transducer.

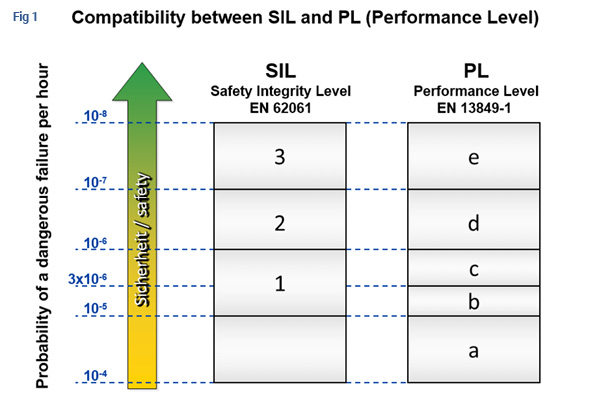

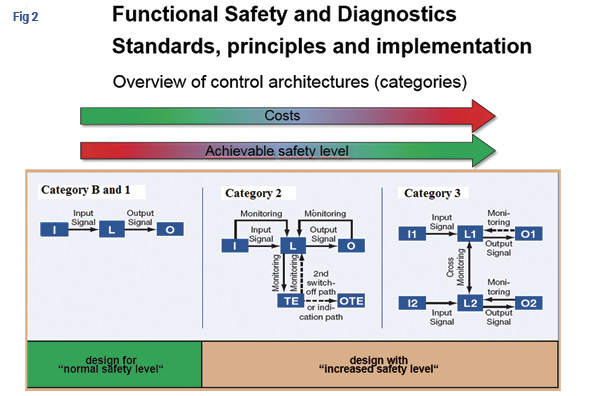

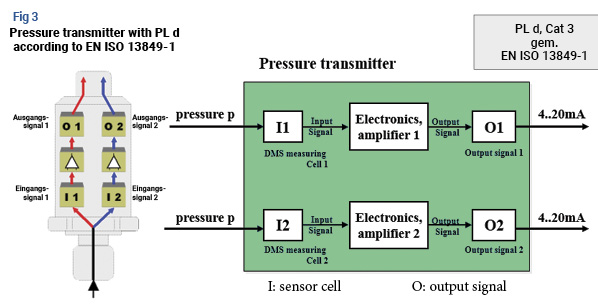

This quantum leap in technology quickly simplified the pressure-sensing challenge for subsea systems on production, drilling, and Remotely Operated Vehicle (ROV) applications. In addition, coupled with this direct compensation transducer (DCT), one customer asked us to go one step further and supply a subsea transducer suitable for use in a system that requires Safety Integrated Level SIL2 or Performance Level D. We were also able to realize this utilizing a dual cell, (with or without) a galvanically separated set of individual outputs from the same transducer; this accomplished the redundancy requirement to achieve suitability for use in systems that require Performance Level D or SIL 2 ratings (see Fig. 2, Category 3). This technology is acceptable for depths up to 20,000 ft. of water depth and in excess of 16,000 Psi system pressures (see Figure 3).

Lastly, our goal was to make the system more user friendly for the production team. This was accomplished by using direct compensation which allows for relocation of a drilling or production system “on the fly” without requiring any reprogramming or resetting of any feedback technology from sensors since the depth is automatically adjusted as depth changes occur. In addition, we work to help the O&G Industry with better, safer and smarter controls. We feel that sensors suitable for use in SIL and Functional Safety systems not only enhance the safety of our most precious component, human life, but also help protect and preserve our environment.