Mobile Hydraulics and Controls for a Rail Car Heating System in the Railroad Equipment Industry

Adobe Stock | candy1812

By Kevin Smith, Vice President of Sales, Scott Industrial Systems

The railroad industry has long relied on innovative technologies to ensure the safety, efficiency, and durability of its infrastructure. One such critical innovation designed for rail service and repair is the mobile hydraulics and control systems used in rail car heating equipment. These systems are designed to heat continuously welded railroad rails up to 260°C (500°F) so they expand to be secured in place while hot. Once cooled, the rails contract to create tension and stability to support the locomotive and rail carloads. This article explores the technical aspects, challenges, and innovations behind the systems incorporated into rail service cars.

The Role of Mobile Hydraulics in Rail Heating Systems

To achieve the precise range of speeds and torque required for heating rails, a combination of hydrostatic drive and mechanical linkage systems is deployed. This setup ensures sufficient power to move the system across the rails at controlled speeds, even on inclines. Additionally, an auxiliary pressure-compensated, load-sensing circuit operates ancillary equipment, such as burner assemblies, blower fans, and vibratory mechanisms.

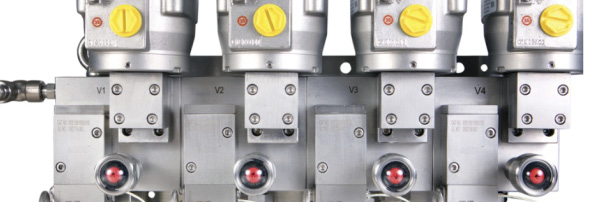

The system’s hydraulic components include a hydrostatic pump featuring pulse width modulation (PWM) control, as well as radial piston motors for the main drive system or vehicle propel function. Pressure-compensated piston pumps supply hydraulic power to the auxiliary functions. Directional control valves, both cartridge-style and sectional-style, manage the hydraulic flow. These components, paired with a hearty mobile control module, create a hydraulic and control system capable of thriving in harsh outside environments.

Control System Operation and Design

The control system is built around a durable mobile PLC control module, programmed with software developed using the CoDeSys environment. This module interfaces with the directional control valves via wired communication and with the diesel engine via the J1939 CAN bus protocol. Analog and digital sensors provide real-time data for monitoring system performance, guaranteeing reliable operation even in austere conditions.

Field Challenges

One of the primary obstacles faced by rail heating systems is operating with minimal downtime in severe outdoor environments. These machines often function in remote areas, where resources for troubleshooting and repair are limited. Downtime can halt an entire segment of the railroad system, making simplicity and reliability paramount. The system’s design simplifies maintenance, allowing field technicians to quickly identify and address issues.

Heating System Configurations

Propane-powered and diesel-powered configurations are available when choosing a rail heating system. The propane system requires controlled propane flow, while the diesel system uses a fan/blower assembly with a closed-loop control system to maintain consistent airflow. Both systems feature independent burner banks to heat each side of the rail, ensuring uniform temperature distribution.

Innovative Features

The rail heating system incorporates a cruise control function conducive to precise speed control. In work mode, the rail car system operates at speeds as low as 0.08 kmph (1/8 mph), a capability unique to the industry. This slow, steady speed is critical for effective rail heating. Additionally, transport mode allows speeds of up to 12.4 kmph (20 mph) for relocating the equipment. Operator controls include an electronic joystick for speed and directional adjustments, along with comprehensive system monitoring and fault indicators used for troubleshooting.

Safety & Maintenance Measures

Safety is key to the system’s design. Real-time monitoring ensures optimal fluid levels and temperatures, while built-in shutdown mechanisms protect against low or overheated conditions. The system also includes “driver presence” technology, preventing the machine from operating in an unmanned state. Maintenance is facilitated using intricate operator manuals, on-site training, and diagnostic tools such as test points and fault indicators. These features prepare railroad industry technicians to efficiently service equipment and minimize downtime.

Historical Context and Evolution

The concept of rail heating systems dates back to the 1950s, an era where mechanical technology was used to perform the task. Since the early 2000s, advancements in hydraulics and electronic controls have revolutionized systems. Modern designs that have been operational for over 15 years continue to set a precedent as the industry standard.

Energy Efficiency and Environmental Considerations

The closed-loop hydrostatic drive system improves fuel efficiency by reducing waste, allowing for longer operating durations before refueling. In the diesel-powered configuration, the shared fuel system between the engine and burners further enhances efficiency. These features contribute to a more sustainable rail heating approach.

Conclusion

Mobile hydraulics and control systems have transformed rail heating in the railroad industry. By combining advanced hydraulic technology, innovative control features, and robust safety measures, these systems guarantee reliable operation in even the harshest environments. As the industry continues to evolve, these systems will remain at the forefront of technological advancement and align with the demands of modern rail operations.