Monitor Equipment Performance

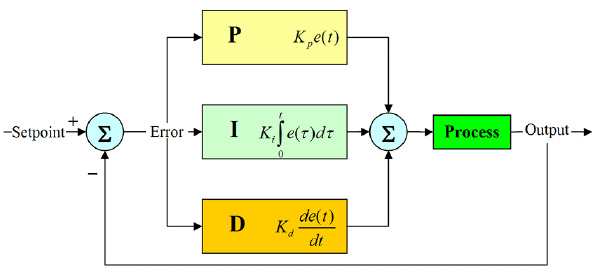

![]() PLCs with PID loops can often be used to monitor equipment performance, sometimes even without adding dedicated sensors. For example, consider a simple hydraulic press where each cylinder is equipped with an LDT and is actuated by a proportional flow control valve with voice coil actuator and integral pressure transducer. The signals from the LDTs and pressure transducers coincide to input to the PLC PID, and the output from the PLC manipulates the valves.

PLCs with PID loops can often be used to monitor equipment performance, sometimes even without adding dedicated sensors. For example, consider a simple hydraulic press where each cylinder is equipped with an LDT and is actuated by a proportional flow control valve with voice coil actuator and integral pressure transducer. The signals from the LDTs and pressure transducers coincide to input to the PLC PID, and the output from the PLC manipulates the valves.

Many modern PLCs offer data-logging capabilities that would allow us to review trends in the control signals for analysis, as well as the PID loop error signals, without adding additional, dedicated sensors. As seals wear out and leakage accumulates, these control signal quantities will increase over time. If we added a case drain flow meter input to the PLC, we could also monitor pump efficiency trends.

Not every hydraulic press application is suitable for this sort of integration; however, many products and processes do benefit from the precision controls and proactive maintenance that are made practical by these technologies.

Justin Sergeant, CFPS