On the Air: How Smart Pneumatics Saves Costs and Helps the Planet

The AVENTICS Smart Pneumatic Analyzer. (Courtesy of Emerson)

By Robert Brezni, Global Account Manager, Fluid Control & Pneumatics, Emerson

At a time when the need to decarbonize economies is at its greatest, manufacturers are better positioned than ever to take meaningful action. The digital transformation of industrial facilities makes it possible for manufacturers of every size to access real-time process data, insights, and diagnostics that can help improve energy efficiency and sustainability across the plant floor. The key is integrating smart technologies and using the data they collect to make decisions that reduce energy use and related emissions.

Many smart technologies are scalable, so facilities can focus their attention in one area and expand from there. For example, compressed air systems are responsible for about 10% of a typical industrial facility’s electricity use, which makes them significant opportunities for savings. By integrating smart pneumatic technologies, operators can collect system data, including airflow, pressure, and temperature, to identify whether and where they are wasting compressed air. With this data, operators determine corrective actions.

The AVENTICS AF2 Series airflow sensor. (Courtesy of Emerson)

Wasted energy in pneumatic systems can be staggering. To put a number on it, manufacturing plants typically lose about 30% of compressed air due to leakage alone. This wasted energy leads to machine downtime and, of course, increased energy costs.

Compressed air helps operate machinery and processes throughout industrial facilities, so its prevalence makes it pivotal to lower year-over-year energy costs. In fact, improvements in the airflow of a plant’s machinery of even just a few percentage points can mean tens of thousands of dollars in saved energy costs each month, depending on the size and nature of the equipment. That translates to hundreds of thousands of pounds of carbon dioxide (CO2) emissions saved. With smart pneumatics like software monitoring and notification solutions to detect leakage, manufacturers often reduce their compressed air energy spending 10% to 20% and reduce their CO2 footprint by 10%.

However, for many manufacturers, this transformation remains a goal rather than a reality. While they may acknowledge the benefits, over 70% of manufacturers lack a data analytics plan and a clear blueprint for success. These companies consider the Industrial Internet of Things and other enabling technologies too complex, costly, and time consuming to implement.

The PACSystems RXi2-BP Edge Computing Device. (Courtesy of Emerson)

But that doesn’t have to be the case. Manufacturers can invest in plug-and-play smart pneumatic solutions that keep installation time and costs to a minimum. They can take the first step toward digital transformation with a closer look at how smart pneumatics saves energy in areas where leaks and losses occur.

Plants improve compressed energy savings through digital transformation in two primary ways: addressing leaks and leveraging the ratio between air pressure and airflow.

Addressing leaks

The most obvious way manufacturing plants lose energy in pneumatic systems is through leakage. When pneumatic system components are subject to wear, leakage can occur and grow over time. The larger the leak, the more significant the energy loss, resulting in wasted energy, a bigger carbon footprint, and higher operating costs. Some operators lose more than $50,000 a year per machine!

In addition to energy loss, a compressed air leak causes a machine’s system pressure to fluctuate, affecting equipment efficiency and even production. As a result, a machine must work harder to compensate. This unnecessary cycling and increased run time raises energy costs, decreases equipment service life, and increases maintenance.

To detect and locate compressed air leaks, companies bring in technicians with ultrasonic equipment to test for them. But leaks often appear, persist, and grow between those periodic, stopgap visits.

On the other hand, smart pneumatics continuously monitors airflow. Some sensors collect and provide real-time insights on flow while also capturing pressure and temperature data in the feed line, enabling advanced diagnoses of the operating parameters. These solutions often easily retrofit to existing machines with the use of edge gateways. Around-the-clock software monitoring detects leaks in near-real time. The software identifies the machine in question and sends notification alerts directly to maintenance staff to investigate further.

Addressing compressed air leaks early also reduces both unplanned and planned (to test for leaks on each machine) downtime, and it improves overall equipment efficiency.

Air pressure and airflow

Some manufacturers may not have the full picture when it comes to the relationship between air pressure and airflow. This means they don’t know the optimal consumption point of compressed air for their manufacturing process. The air pressure in their industrial machines may be higher than it needs to be. When equipment consumes more compressed air than necessary, it consumes more energy, which raises energy costs and CO2 emissions.

Smart sensors and an edge computing device collect data about air pressure and airflow. By analyzing the edge analytics of the pneumatic system, plants gain a clearer picture of the relationship between air pressure and flow. By lowering the overall pressure of their pneumatic system, they reduce airflow to a certain point while maintaining the same cylinder cycle time.

Finding the optimal ratio between pressure and flow reduces compressed air consumption, energy costs, and CO2 emissions without affecting production.

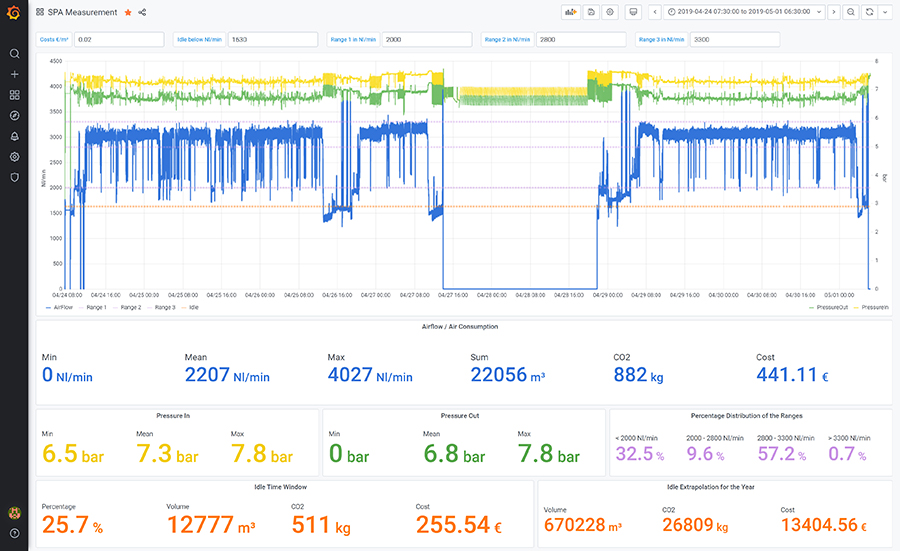

Live data captured by flow sensors using the AVENTICS Smart Pneumatics Analyzer. (Courtesy of Emerson)

Manufacturers understand that sustainability is not just a trend. It’s their responsibility to reduce energy use and greenhouse gas emissions however they can. Monitoring compressed air in pneumatic systems is one place to start. When companies monitor and record machine performance, they can be confident they are using energy as it’s intended, and they are stopping losses before they can grow.

The flexibility offered by today’s smart pneumatic devices makes it possible for manufacturers to tailor their digital transformation in ways that work for them. Partnering with an automation expert with a proven history in smart pneumatics and fluid power applications can help a company of any size recognize its specific circumstances, set sustainability goals, and identify solutions. With the right solutions in place, manufacturers can take meaningful action to make meaningful change.•

Case Study: Saving Energy in a Brownfield Setting

A global producer serving the automotive industry recently took steps in its digital transformation by focusing on the energy lost through compressed air leakage and air consumption. The company partnered with Emerson to monitor and measure the amount of energy the line used.

Like most brownfield applications, this production line included legacy equipment that came from different suppliers. A power supply, Ethernet bus coupler, power meter (one per circuit), and IO-Link, which included eight available ports for sensors, made up each meter box. Current transformers were located either inside or outside the meter box, and these modules all had to be installed upright to allow air circulation. Making the setup even more complex, there were a limited number of Ethernet access points to work with. Expanding would require considerable investment.

To meet the needs of this complex setup, Emerson recommended its AVENTICS Series AF2 Sensor, an easy-to-use airflow sensor that measures flow, pressure, and temperature and monitors air consumption in pneumatic systems.

The AF2 is ideal for a collection of legacy machines like this for a couple of reasons. First, the compact sensor is easy to assemble and install on existing machines and pneumatic systems. Second, the AF2 has IO-Link and Ethernet communication options. The sensor is easy to integrate into air preparation units and gives manufacturers the option to operate as a stand-alone version. With a colored rotatable LED display that provides clear feedback, the AF2 sends notification alerts to users when it detects a leak so they can take action. This simple IIoT-enabled device allowed the company to invest in energy savings while keeping installation time and costs to a minimum.

After choosing a sensor, Emerson helped the company monitor and measure the amount of energy the line used by temporarily connecting the AVENTICS Smart Pneumatic Analyzer to one machine. The SPA, which provides pneumatic system analysis at a glance, recorded, analyzed, and visualized the line’s air consumption during the production process. The team was able to read the real-time air consumption, which the SPA displays in norm liters per minute, alongside average and maximum values to quickly identify trends and anomalies.

The data collected from the SPA helped the company decide whether Emerson’s PACSystems RXi2-BP Edge Computing Device was worth investing in. In simple terms, the device interprets and displays incoming AF2 sensor data. The information is recorded and displayed on a live web-based dashboard and gives users even more energy insights without additional software. The SPA data revealed that the PACSystems RXi2-BP Edge Computing Device helped the company save energy and associated cost.

Emerson supplied approximately 180 AF2 flow sensors to meet the production line’s needs, along with the PACSystems RXi2-BP Edge Computing Device. This system monitors pneumatic air consumption and generates and interprets machine data, giving the automotive producer actionable insights. As a result, the company found areas for improvement, including reducing peak power consumption, optimizing maintenance costs, and avoiding downtime. It plans to continue optimizing its machines to use less energy.