Choosing the Right Fluid Power Sealing Solutions for Construction Equipment

By Ryan Webster, Director of Sales and Engineering, Hallite

Demand for heavy construction equipment is continuing to grow. According to a recent report, the global market is expected to exceed a value of $230 billion by 2025. This is a significant increase from a value of $145 billion in 2018.1 What does this mean for suppliers supporting original equipment manufacturers (OEMs)? It signifies increased demand for the most robust and efficient products and materials to meet greater productivity requirements.

Seals, wipers, and bearings are included among the high-performance products that are essential for hydraulic fluid containment and optimal cylinder performance. They also help protect people and the environment. OEMs rely on knowledgeable suppliers to select construction equipment products designed for the temperature, pressure, and shock loads of severe operations. Their expertise helps equipment design engineers avoid costly, disruptive product and material failures.

Let’s review some field-proven seals that the construction equipment industry has successfully used for decades.

Focus on the task, then the seal

Earth moving equipment, dump trucks, cranes, and heavy-duty off-road vehicles comprise a long list of construction and infrastructure worksite tools used worldwide every day. Each machine is powered by at least one hydraulic cylinder, and each cylinder relies on a variety of seals. However, no single seal size or profile fits all. The solution depends on the application or task each piece of equipment performs. This should be the primary focus. Here are three of the most common and consistently effective sealing products based on the important work they help the construction equipment perform.

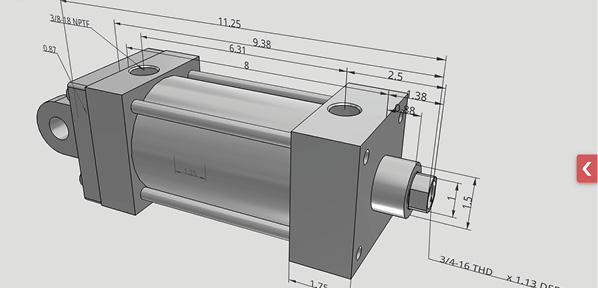

1. Unitized piston

The unitized piston has been in use by the industry for years, so it can sometimes be taken for granted. However, it is important to note that it reliably performs in high-pressure environments at 5,000 to 10,000 psi (345 to 690 Bar) continuously. It is available in hundreds of production sizes and offers simplified installation owing to its one part assembly. Specifically, the unitized piston is an assembly of seals and wear elements, which are shipped to the user as one singular part number. Thus, easing logistics and providing a significant improvement in performance and seal life. Performance, of course, comes from the seal’s tight tolerance machining and fit to the cylinder bore which helps prevent large metal-to-metal extrusion gaps and high side load impact.

Imagine heavy-duty earth moving machinery on a commercial worksite scooping and plowing through rock and granite to trench for placement of underground cable. The unitized piston’s robust design and capabilities protect the seals located inside the machine’s hydraulic cylinder. In one example, a unitized piston helped a compact equipment OEM extend the cycle life of its hydraulic cylinder seals by five times more than what was possible with the seals that were originally designed into the machine. The unitized piston’s durability helped the manufacturer address its warranty issues.

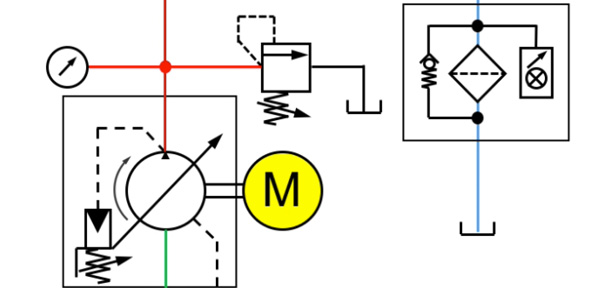

2. 714 piston seal

2. 714 piston seal

In heavy-duty construction applications, high shock load and heat are prominent. The 714 piston seal is displacing legacy five-piece designs because of its simplified assembly process and high durability. An OEM used it to upgrade the steering element in one of its machines. After 1.2 million cycles under extreme conditions, the seal continued to perform well, far outpacing what was used previously.

The 714 features a step-cut split based on a specialized manufacturing process that prevents air pockets and protects against pressure spikes in heavy work environments. The advantages can be observed in the bucket lift cylinder where, by nature of the work performed, seals take a beating. In such applications, machines do much more than scoop dirt. They lift and handle a wide range of other interesting work.

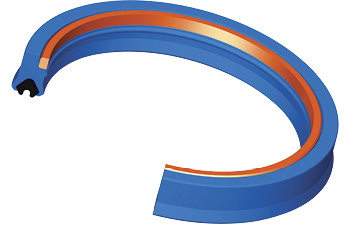

3. 621 rod seal

3. 621 rod seal

The 621 rod seal features a secondary sealing lip located behind the primary sealing lip to stabilize the seal in the gland. An NBR energizer ensures that the seal’s primary sealing lip maintains contact under low- and high-pressure conditions and helps to act as a buffer to absorb shock loads. The 621 is rated for surface speeds 3.0 ft/sec (1.0 m/sec), temperatures from -50° to 230°F (-45° to 110°C), and maximum pressure 10,000 psi (700 Bar). It incorporates an acetyl anti-extrusion ring to withstand extreme pressure peaks, even with wide extrusion gaps. An added advantage in construction equipment applications is the 621’s composition of materials that are compatible with biodegradable and water-based fluids. In today’s environmentally conscious operating climate, this is a must.

In conclusion, as construction projects increase in volume and scale, so does demand for the most efficient and highest performing sealing materials and designs. The work performed by each machine will dictate its requirements. Partnership with an experienced seal manufacturer can help OEMs navigate the process of selecting the right solutions to meet their operating needs.

Ryan Webster is director of sales and engineering at Hallite. He can be reached at rwebster@hallite.us.

1 Zion Market Research Report titled: “Heavy Construction Equipment Market by Type (Earthmoving, Material Handling, Heavy Construction Vehicles, and Others), by Application (Excavation & Demolition, Heavy Lifting, Tunneling, Transportation, Recycling & Waste Management, and Material Handling), and by End-User (Construction & Manufacturing, Public Work & Railroad, Oil & Gas, Mining, and Others): Global Industry Perspective, Comprehensive Analysis, and Forecast, 2018–2025”