Piab Offers Batch Volume Functionality in piFLOW

The level of automation in the food, pharmaceuticals, and chemicals markets is developing rapidly due to the adaptation of new solutions globally. The acceptance is increasing thanks to automation’s obvious benefits, such as improved product hygiene and employee safety. Heightened consumers’ expectations and legislative regulations also force manufacturers to re-evaluate their processes, but some still choose not to invest. Currently, manufacturing plants often consist of separate silos of automation in which process steps are not entirely connected.

One of the main concerns against adaptation is an organization’s lack of acceptance of new technologies. A high fluctuation rate and the scarcity of trained, competent operators and technicians makes it difficult to take the leap. Therefore, new equipment must be as user friendly as possible to decrease employee onboarding time and reduce the possibility of human error.

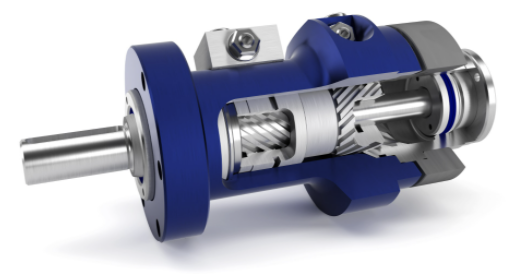

Piab has taken these requirements into account in its new product series, the piFLOW Batch Volume Optimization, which Piab offers beside the standard piFLOW vacuum conveyor range. The Batch Volume Optimization functionality is easy to maintain, compliant with industry standards, and enhances productivity dramatically.

The vacuum conveyor takes solids from a pickup point and releases them into a receiving vessel or a piece of equipment in batches. Batch Volume Optimization features a level sensor. Once the conveyor is filled up by each cycle, the sensor automatically triggers the release process. This way, operators can set the conveyor up quickly, and the automatic level sensing adds an extra layer of safety, which protects the equipment from unplanned maintenance.

Batch Volume Optimization represents a medium level of automation in the piFLOW range. The full range spans from the well-known and reliable standard product series to Auto-tuning, a fully automated vacuum conveying solution. No matter the application, there is a piFLOW tailored to it.

For more information, visit www.piab.com.