Pure and Simple: A Servo Valve that Streamlines Hydraulic Control

By Ben Dupre, Senior Technical Writer, HydraForce.

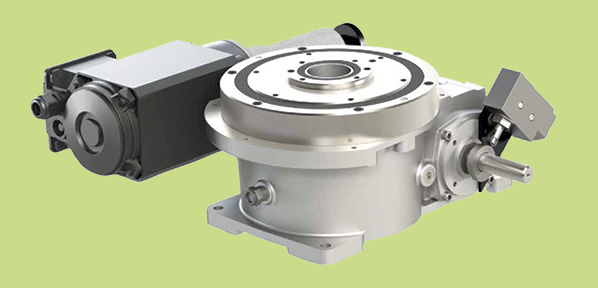

HydraForce recently added to its ExDR family of electronic valve drivers. The new ESDR-0201A was developed as a closed loop control for servo valves. The driver is built on the successful ExDR platform of coil-mounted integrated valve drivers. This version features two outputs for driving two-coil proportional valves, but it can also be used with single-coil valves. It has a single 0-5 V analog input that forms the feedback leg of the PID control, along with a 5.5 V (200 mA) reference voltage to power a sensor or other input device, such as linear variable differential transformers used with servo valves. It also includes an SAE J1939 CAN network interface that receives the PID set point, and it can transmit diagnostic messages and status information back to the main vehicle controller.

The ESDR simplifies control of hydraulic functions on the machine and greatly increases their accuracy, repeatability, and reliability. It uses a sophisticated closed loop PID control that drives proportional hydraulic valves precisely while compensating for factors such as coil temperature, valve-to-valve manufacturing variation, hysteresis, and hydrodynamic forces.

Testing with HydraForce SP type proportional directional controls demonstrated a significant decrease in hysteresis over open loop control using the same components. Valve washout performance also made notable increases, and the control demonstrated near-perfect linearity across the control range from A coil to B coil.

What makes these advances possible is position feedback. The control is able to drive rapid small changes in the coil current to maintain the desired position at all times. Other forms of feedback are possible using sensors such as pressure transducers, speed sensors, and position sensors like LVDT.

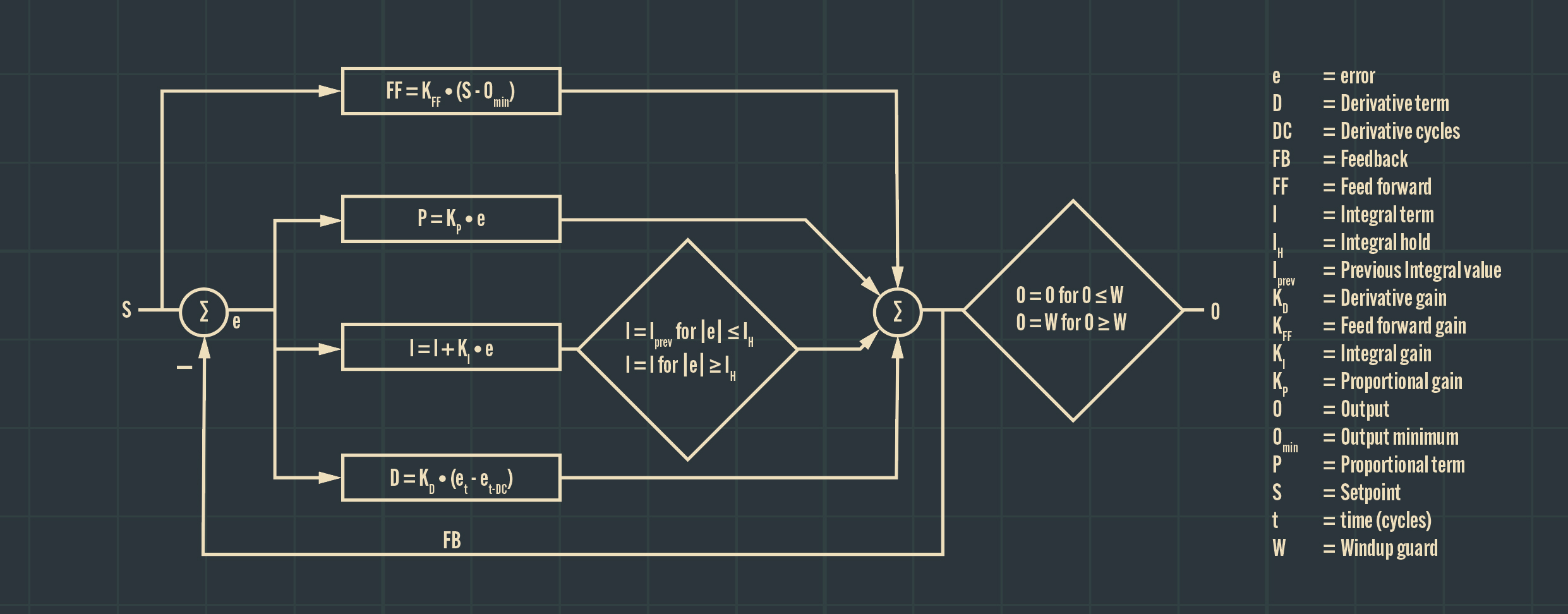

Closing the loop locally (i.e., on the valve) relieves the main vehicle control from performing PID functions and makes for faster and more efficient control systems. The HydraForce ESDR is optimized for this. The control contains a full-featured set of PID tuning parameters, including feed-forward for faster response.

HF-Impulse configuration software

To allow configuration, programming, tuning, and troubleshooting of valve drivers and electronic control units, HydraForce provides HF-Impulse. This purpose-built software allows configuration of the communications parameters and those settings particular to each device type. It also facilitates programming control logic for ECDR-style configurable drivers, and it serves as a troubleshooting tool with real-time monitoring of I/O and diagnostic messaging parameters for CAN devices.

HF-Impulse lets the user define parameters for certain input errors. When the device encounters these conditions with the input signal, it raises a DM1 message on the CAN bus. Users can also define the PWM frequency for A coil and B coil outputs individually.

HF-Impulse provides the following PID tuning parameters:

- Proportional gain: The output is proportional to the error.

- Derivative gain: The output is proportional to the previous error.

- Integral gain: The output is proportional to the rate of change of the error.

- Feed-forward gain: The output is proportional to the desired set point.

- Windup guard (output limit): The output is limited to protect against derivative windup.

- Derivative cycles: The derivative term is averaged over this number of cycles to dampen it and prevent overshoot.

- Integral hold: The integral term is limited for error greater than the hold value.

- Duty cycle minimum: The output cannot fall below this minimum value.

You can specify CAN network parameters such as:

- Transmit analog input value (enable).

- Set point message parameters: Select basic or extended joystick presets or choose custom for full control.

- ESDR communication: CAN address and baud rate.

- Set point message lookup table: Define the minimum/maximum message values and output limits.

Because the ESDR is designed as a closed loop control, output scaling is not necessary and therefore perfectly linear between minimum and maximum values.

Users can define parameters for how HF-Impulse communicates with the device. This requires a USB-to-CAN adapter, and three types are supported. You can also search the connected network for your device and perform firmware updates.

HF-Impulse charts operating telemetry in real time for monitoring, tuning, and troubleshooting activities. You can also export the data in CSV format for analysis. All data is plotted on a scale 0 to 5000 mV so the relationships of the values can be easily understood.

The ESDR-0201A valve driver.

Potential applications

The ESDR-0201A has potential as a closed loop CAN control in a distributed control network. The main benefits are controlling a device by CAN message and distributing the closed loop control to lighten the load on the main vehicle control, forming a faster and more responsive system overall. Here are some potentially useful applications.

Flow control with LVDT sensor. For applications such as auto steering that need precise and repeatable flow control, you can use the ESDR with an LVDT position sensor that feeds the spool position back to the 0-5 V input.

Position control. When used with a position sensor integrated to the cylinder, the ESDR controls its position. The PID loop can be tuned to match the desired response. For example, it can be optimized for speed or to minimize overshoot/overcorrection.

Speed control. The ESDR can provide closed loop motor speed control when used with a speed pickup that provides an analog output.

Force control. Users can control the force of a press, grapple, or other clamping device using a proportional relief valve with a pressure sensor to communicate the load to the ESDR.

Torque control. Users can easily control the torque of a hydraulic motor with a proportional relief valve, using a pressure sensor for feedback.

The benefits of closed loop PID control are well known to industrial process controls. To date the technology has had a more targeted impact in the mobile hydraulics sector, being adopted primarily in high-spec, less cost-sensitive applications and on functions with critical performance demands. The demand on mobile vehicle controllers to execute PID across the spectrum of machine functions drives applications into faster, higher cost, higher I/O devices. To break down these barriers to adoption, HydraForce offers a unique distributed control strategy that allows simple plug-and-play CAN networked, coil-mounted drivers that can be easily added to individual functions as needed. Building a modular mobile machine architecture in this way gives vehicle designers flexibility to develop solutions that fit within ever-tightening cost and performance parameters.